Interview with Mr. Kunal Kapur – Managing Director of Coats Digital

Coats Digital was formally launched in September 2019 as the official software business of our Parent company, Coats Group – which has a pioneering history in producing innovative threads, yarns and fabrics, since its inception, in 1755.

Kohan Textile Journal: First of all, please tell us about Coats Group, the history of Coats Digital and its success story in the textile and fashion sector.

Mr.Kunal Kapur: Coats has long acknowledged that the future of fashion is digital – and decided to build a dedicated technology/software business to ultimately help spearhead the much-needed digital transformation of the fashion industry – which has been notoriously stuck in the past. For Coats, it’s all about creating exceptional customer value and delivering 100 percent on its strategic pillar of digitization.

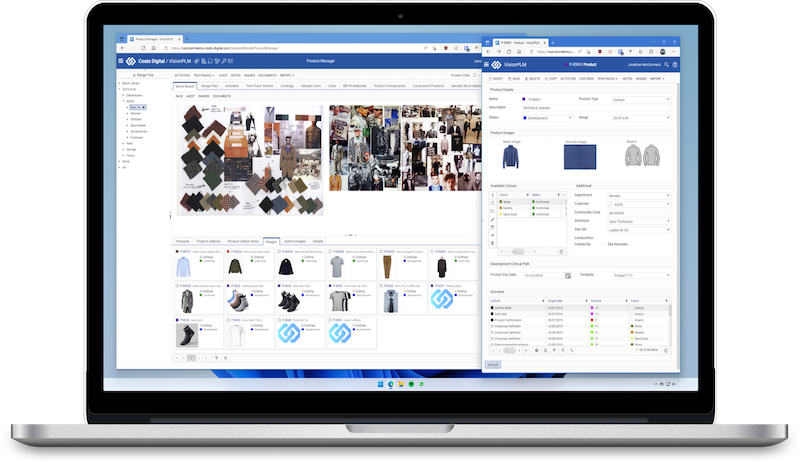

Coats Digital’s initial technology portfolio brought together leading fashion supply chain solutions including GSD and FastReact to deliver a unique, robust, connected ecosystem of best-in-class technologies that enable brands and manufacturers to step up their digital agendas quickly and solve their critical pain points seamlessly.

With the acquisition of these leading software solutions, Coats Digital offers a rare combination of industry depth and technology expertise to make a real difference in addressing business-critical challenges across the supply chain – not just specific, select areas – but those that help eradicate key problems from plan to pack – that the industry has been contending with for years.

The industry knows FastReactPlan (formerly Fast React) and GSDCost (formerly GSD) as being the go-to solutions for production planning and garment costing within the value chain.

GSDCost remains the de-facto international standard for establishing accurate method-time-cost benchmarks. This method analysis solution supports a more collaborative, transparent and sustainable supply chain, in which brands and manufacturers establish and optimise ‘International Standard Time Benchmarks’ using standard motion codes and predetermined times.

We have continued to build on this fantastic heritage, by adding and enhancing, a unique fabric optimization solution, FastReactFabric – which offers an effective way to maximize fabric utilization and reduce waste by accurately estimating fabric consumption at the buying and cutting stages. With between 70-80% of fashion manufacturing investment down to fabric costs, this solution offers a surefire way to significantly reduce costs and unnecessary fabric wastage in one swoop.

Ultimately, our goal is to quickly establish a valued ecosystem of superior, connected solutions that provide the real-time data insights and transparency that the fashion supply chain increasingly needs to deliver real growth, more efficient operations and meaningful sustainable practices across all global concerns. Our eco-system of market-leading solutions supports design and development; fabric optimization; method-time-cost reform, production planning and control, and shopfloor execution. These solutions continue to deliver significant ROI to our customers and ensure that their business processes are robust, enabling them to adapt and withstand any market dynamics that evolve in the future. Our customer success is paramount.

Kohan Textile Journal: What is FastReactPlan exactly and how can it help apparel and garment manufacturers on their digitalization journey?

Mr.Kunal Kapur: Our production planning and control software, FastReactPlan, supports a faster, more reliable order confirmation process and production plan which is optimized for delivery, efficiency and speed. Indeed – our customers are generally realizing a reduction in lead times of up to 30%, improvements in OTDP between 10-30%, and around a 10% increase in productivity – simply by implementing this one business-critical solution.

However, just recently, a key customer based in Thailand – global outerwear, sportswear and protective equipment specialist, VT Garment, realised unprecedented ROI benefits with FastReactPlan. The company not only improved its overall productivity by 95%, plan accuracy by 92% and doubled its on-time delivery performance, but the adoption of FastReactPlan also played an instrumental role in securing the company a ‘Golden’ Thailand LEAN award in recognition of its outstanding LEAN manufacturing and management processes.

FastReactPlan is the market-leading production planning and control solution that is trusted by over 500 customers and is embedded in over 2,000 factories across 40 countries. It has been developed and delivered by industry experts and its easy-to-use interface supports rapid user adoption and accelerated business benefits.

Proven to deliver significant measurable and sustainable improvements, FastReactPlan supports a typical return on investment in less than 12 months.

Kohan Textile Journal: What are the unique features of FastReactPlan and why is it used by the leading garment and apparel manufacturers across the globe?

Mr.Kunal Kapur: FastReactPlan’s highly visual, flexible ‘drag and drop’ approach to planning allows effective master planning across multiple factories, as well as fast, detailed and accurate scheduling of manufacturing lines/machines. Critical pre-production activities and material requirements are dynamically driven by the latest plan on a LEAN ‘just in time’ basis, supporting the reduction of inventory and lead time.

FastReactPlan is proven to optimize production processes by providing detailed, accurate planning and order confirmation resulting in a smoother, more efficient production flow. It also digitally connects teams across the business, so that materials and pre-production priorities can be quickly ascertained. The solution provides increased visibility, coordination and control to enable the elimination of unnecessary overhead costs in time and material resources.

The solution’s LLAPS (Lower-level Automatic Planning System) feature eliminates the need for manual calculation of reports, which are often time-consuming and error-prone. This feature allows for the more efficient planning of production lines, enabling the business to handle a wider range of orders and make more informed decisions.

This program feature allows companies to easily compare different plans and select the most optimal option, based on factors such as cost, efficiency, and delivery time. As a result, companies have the ability to view plans from multiple perspectives, providing a more comprehensive understanding of its production capabilities and limitations. The complete automation of planning processes also frees up time for staff to focus on other important tasks, such as problem-solving and enhancing the customer experience.

FastReactPlan’s drag-and-drop feature facilitates seamless planning of the main manufacturing process – typically sewing – by using standard minutes, efficiency profiles and start-up/training curves. Schedules for supporting bottleneck processes – such as embroidery, screen printing, etc., are, consequently, automatically and dynamically driven by the sewing plan. The solution quickly imports production updates on the plan versus actual reports. Color-coded alerts with drill downs menus additionally enable a rapid response to any challenges or last-minute change requests that come in, which effectively eliminates the need for stressful firefighting on the factory floor.

The material requirements within FastReactPlan are dynamically calculated on LEAN pull principles, based on the latest sewing plan. Inventory and open manufacturing production orders (MPOs) are imported from the main business system to provide a completely up-to-date picture of material demand and supply. This enables fabric mills and other fabric suppliers to have clear visibility of priorities so they can meet sewing plan requirements from the very start of the planning process. This results in on-time production runs and smoother production flows and less raw material waste – which can significantly help companies meet their sustainability targets.

For businesses with multiple factories across different countries, FastReactPlan often proves a blessing, as the planning process starts on a high-level planning board with a control tower view, so that the master planner can manage total demand (projected and confirmed orders) along with capacity, to benefit from a consolidated picture of materials and pre-production activities across the whole global business.

Kohan Textile Journal: What can we expect for the global textile and fashion sector in 2023?

Mr.Kunal Kapur: During past lockdowns, eCommerce accelerated exponentially, and although brick-and-mortar retailing has reclaimed some of its lost market share, we expect that online shopping will continue to be the preferred choice for a growing global population with increased access to the Internet and smartphones, along with more time spent at home due to growing flexible working initiatives.

If the fashion industry can adapt and respond quickly to new consumer expectations around sustainability, more personalized fashion customization, and more agile production turnarounds on fashion trends – then it will undoubtedly be able to better navigate a notoriously precarious trading environment.

Evidence increasingly suggests that all players in the fashion supply chain will be unlikely to successfully navigate this consistently changing landscape, or meet the exacting expectations of a more demanding consumer, if they don’t invest – and continue to invest – in technology and digitization programs that will help to mitigate the challenges ahead.

It’s easy to see why the BOF/McKinsey – State of Fashion Report 2023 highlights that two-thirds of apparel chief purchasing officers expect digitization to be the most important capability for suppliers to grow in the year ahead.

Looking further out, with Deloitte’s Apparel 2025 Report predicts that technology will advance greater personalization and customization of styles to enable consumers to modify every aspect of each article of clothing they buy – including trim, sizing, materials and even down to fundamental design – then only those manufacturers that have the digital processes in place to ensure rapid speed to market and accurate product data will be able to fully capitalize on Deloitte’s estimation that customizable apparel will claim between 10 to 30 percent of market share by 2030.

Add to this the fact that brands are increasingly wanting to respond deftly to fast-changing style trends driven by social media – then the emphasis on speed, and shorter, more complex orders will undoubtedly be more acute in the years to come. We predict that retailers are certainly likely to embrace this change readily, if it reduces the risks of surplus inventories.

Kohan Textile Journal: Tell us about your latest products, research and development, new investment and …

Mr.Kunal Kapur: We are making a big move towards cloud-based computing and new, ground-breaking SaaS products that will significantly fuel our growth, so we will be very busy this year with a number of industry-changing product launches that will incorporate AI and consolidate various best-in-breed products together, so that information can flow even more seamlessly and provide greater insights to customers.

Most of our offerings are available as Software as a Service (SaaS) solutions, so all potential customers need is access to a simple web browser whether from a mobile device or a traditional computer.

Coats Digital is a completely unique business that we are very proud of. We are really excited about the future of Coats Digital since our main competitive edge derives from the 250 years of domain knowledge from Coats Group, as well as our technical expertise through our gold-standard products. We have big plans for Coats Digital and our key focus areas for the short/ medium terms include the areas of innovation, talent development, customer partnerships and new product launches. These four areas will provide the key impetus for our 2023/2024 growth plans.

Firstly with regards innovation, we will continue to think ahead for our customers, so that we build innovative features into our products, including AI where possible.

Investment in our people is the cornerstone of any technology business, and we will also continue to invest heavily in the training and development of our teams, so that we retain our edge as true experts in the fashion supply chain. By consistently providing our teams with exposure to different situations, new benchmarking exercises and customers based across the globe, we will ensure our practices remain the very best across the industry.

We have a new, revamped and joined-up ‘Go To Market’ strategy this year to ensure we get closer to all our customers. Various customer-facing teams within our commercial, customer support, customer success and solutions consulting teams, for example, are working harder than ever before to connect with customers in more meaningful ways. Moreover, through our recently launched ‘Customer Connect’ program our engineering and implementation teams will also be spending quality time with customers, so they can fully understand their needs and can receive valuable, real-time feedback on our products & services.

Kohan Textile Journal: Sustainability and recycling are important subjects for apparel manufacturers all around the world. How can Coats Digital help manufacturers to design a better sustainability roadmap?

Mr.Kunal Kapur: There is no doubt that industry-wide digitization will play a crucial role in the facilitation of truly accountable and meaningful sustainability actions and Coats Digital is playing an instrumental role in helping to facilitate positive change.

Recently launched FastReactFabric is a unique market offering that will enable fashion manufacturers to significantly reduce fabric costs by up to 2.5%; shrink fabric buying and planning times by 95%, and provide 100% fabric tracking, in order to further advance sustainability credentials and reduce overall fabric remnants that so often end up in the landfill.

FastReactFabric combines Coats Digital’s previous industry-leading IntelloCut and IntelloBuy solutions into one single platform, providing a closed-loop, continuous 360-degree feedback ecosystem between buying and cutting operations, so that fashion manufacturers can accurately procure and utilize fabric effectively – reducing waste, boosting efficiency and significantly increasing their bottom line.

A new focus on people, planet – and performance – has highlighted that consumers, governments and all industry corporations are increasingly being held to account for what and where they buy; what and where they produce – and the net impacts their actions have on the world. The fashion industry has a lot to redress here.

The only way to prove that meaningful steps are being taken to drive a more sustainable path – will be through the evidence of data – and data cannot be properly harvested without the systemization and automation of core products and processes across the apparel and footwear supply chains.

This is why our industry-leading production planning and control solution, FastReactPlan, has proved so crucial for many fashion manufacturers wanting to adopt a more sustainable path, since the solution often acts as the lynchpin of their digitization roadmaps. The ability to automate time-consuming and arduous capacity and production planning processes ultimately enables manufacturers to realize such huge time efficiencies and meaningful data insights across the production process, that they have considerably more bandwidth and resources to focus on making better, informed decisions about how to make and achieve new sustainability goals.

Our GSDCost solution is also proving instrumental in supporting a more collaborative, transparent and sustainable fashion supply chain, where brands and manufacturers share a common language and standards. By facilitating accurate manufacturing cost predictions, fact-based negotiations and more efficient garment manufacturing processes, GSDCost is helping to significantly reduce carbon footprints, by eliminating raw material and finished goods waste.

With a strong commitment to putting the fashion supply chain on a more efficient and profitable, yet ethical and more sustainable path, we recently developed a Fair Wage Tool for GSDCost, in partnership with the Fair Wage Network, so that manufacturers can effortlessly factor into order quotes, fair wages for their countries of manufacture. We hope our new tool will prove invaluable to manufacturers and brands alike in their quest to not only meet impending new compliance legislation around fair global working practices but also help to meet growing consumer demand for more sustainable and ethically produced fashion.

Kohan Textile Journal: At the end, you can add any other information that you think is interesting for readers in the EMEA region and a better interview.

Mr.Kunal Kapur: Coats Digital leverages its deep industry and technology expertise to create and deliver business-critical software solutions which are proven to digitally transform the way fashion companies design, develop, cost, source, plan and manufacture.

Our apparel, footwear, and textile-specific solutions harness industry best practices and the latest technology to improve agility, speed to market, efficiency, transparency, and sustainability, and are trusted by over 1000 brand and manufacturing customers, across 55 countries around the world.

Read about the significant ROI our customers have achieved with Coats Digital solutions here.