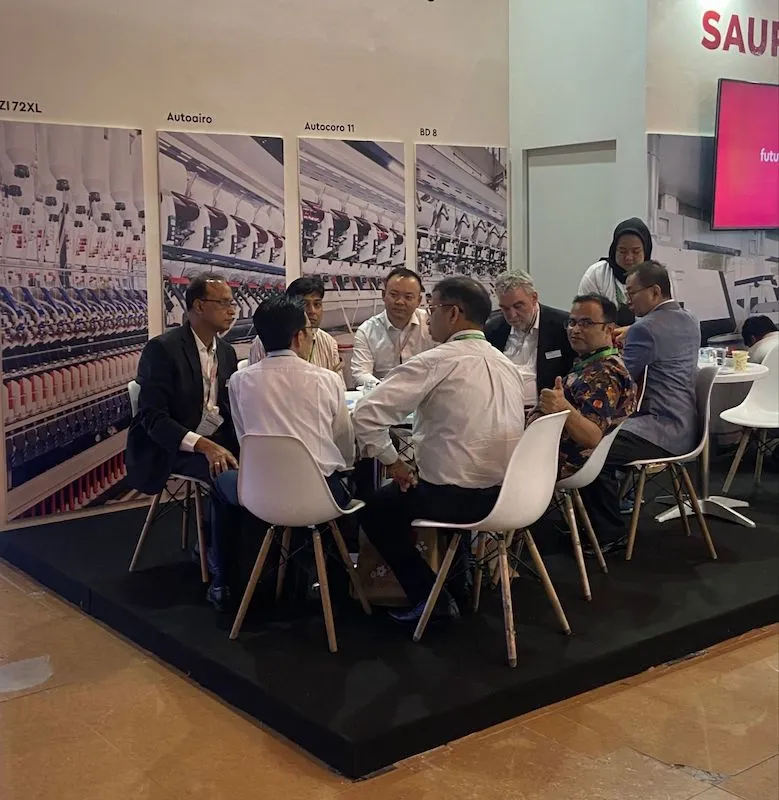

At the Indo Intertex exhibition in Jakarta, Indonesia, you will find Saurer from 20 to 23 March 2024 in hall D1, booth A 11. Meet with our experts to learn about our latest spinning and twisting solutions that incorporate energy-saving features, digitalisation, and automation. Moreover, we offer retrofit and upgrade solutions to further reduce energy consumption.

Saurer is the only supplier that can offer all five end-spinning applications for staple fibres. This puts Saurer in a unique position to advise the Indonesian customers on the best application for their specific needs. The sales and service team at Indo Intertex is looking forward to discussing customer projects and showing them the impact Saurer’s spinning and twisting applications can have on today’s textiles.

Recognising the needs of the market, Saurer provides a variety of options for the use of recycled fibres in all stages of the spinning process. The Saurer portfolio offers the right solution for every application, from fine to coarse yarns, from virgin fibres to recycled fibres. Saurer spinning and twisting machines guarantee maximum productivity with minimum energy consumption.

Every single “Watt” that spinning mills can save is important for our planet. That’s why Saurer offers retrofit and upgrade solutions to reduce the energy consumption of existing spinning machines, as well as upgrade and retrofit kits for processing recycled fibres.

Saurer’s ring spinning portfolio is the ideal solution for all spinning mill requirements. The ring- and compact-spinning machines are designed to deliver excellent yarn quality, while being equipped with energy saving solutions and Texparts quality components.

“For ring and compact spinning machines, we now offer the Twinsuction option to reduce energy costs,” explains Jan-Henri Wiggers, Area Sales Manager for South East Asia. “Customers who want to process recycled yarns on ring- or compact-spinning machines will benefit from the speed optimisation function, which regulates the spindle speed according to the amount of yarn breaks or the self-cleaning function of the Impact FXpro compacting device.”

The latest developments in twisting and cabling technology will be explained by Saurer experts. “The CompactTwister offers new standards in twisted yarn quality, is very flexible and robust, requires less space and is easy to maintain,” says Tapas Nandi, Regional Sales Director Twisting. “With our twisting technology, we have drastically reduced energy consumption, resulting in lower costs per kilogram of yarn produced. This new technology uses digitalisation and sensors to monitor every step of the production process, ensuring the required quality and reducing waste and production costs.”