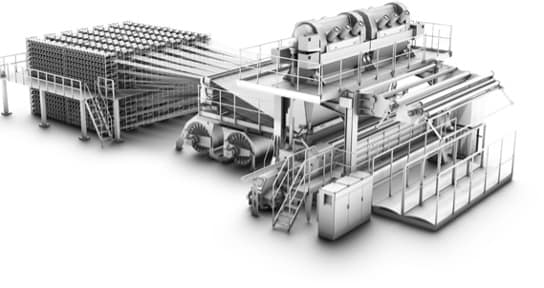

Low pile technology for 5m wide ‘light carpets’

Trends in the carpet industry are changing faster than ever before. The carpet is no longer an heirloom that is passed on from generation to generation but a fashion item used for just a few years. Television programmes and magazines on interior decoration now have a big impact on what consumers buy. This means carpet producers need a carpet weaving machine that is flexible and can keep up with the trends – one like the Stäubli ALPHA 500.

One of the latest trend is low-density velour carpets, carpets with very low pile. Traditional velour looms can weave very fine high-density carpets but only at rather low productivity levels. That makes these carpets too expensive for the consumer who just wants to follow the latest trends.

Low pile for light weight

Stäubli ALPHA 500 UNIVERSAL weaving machines enable the weaving of carpets with a pile height of 3mm (the 4m wide model) and 4mm (the 5m wide model), with pile heights similar to traditional velour carpets.

By using cotton wefts and a special ground weave structure, these carpets woven on ALPHA are very soft and easy to fold, just like ‘real’ velour carpets.

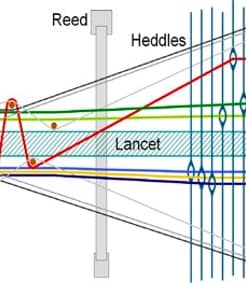

Weaving carpets with such low pile heights requires lancets in order to preclude the problem of tight pile threads pulling the top and bottom carpet together.

In its broad product range, Stäubli offers 6mm lancets for its double rapier weaving machines, allowing pile heights – before shearing – of less than 3mm. Such lancets can only be used on two-rapier looms.

Binding technologies for vintage carpets and easy folding

By having some of the dead pile threads float between the pile, the pile height appears to be even lower, and the carpet back is made softer as well.

“Constant pile height and freedom in weaving”

With the LX2493 Jacquard machine, weavers can level the pile-yarn heddles in the middle position so that they are above or below the unique Schönherr low lancets. The pile-yarn heddles, except the one in patterning action, are not hindered by the lancets. This solution offers constant pile height plus maximum freedom in weaving (as if without lancets)

– for minimum shearing loss and perfectly even surfaces.

BINDING TECHNOLOGY

Magic Weft Effect Duo for a realistic ‘used’ look

This requires a full 3-position Jacquard such as the Stäubli LX 2493. The designer can vary the length of the pile floats to create a ‘vintage look’: Longer floats show more between the pile than short floats, creating the impression of worn areas.

A standard Rep 2/2 ground weave structure normally gives quite a stiff backing fabric, but with the electric dobby UNIVAL 500T on a Stäubli system different, far more flexible ground weave structures can be used, making it very easy to fold the carpet.

ALPHA features decisive factors for economical production

Traditionally velour carpets are woven with very fine silk or viscose yarn, but the Stäubli ALPHA 500 series allows weaving with thicker – and thus cheaper – yarn of any material. Carpet yarns, like PP (polypropylene), PAN (acrylic) and PES (polyester) can be used.

Velour weaving machines are generally not wider than 3m. The ALPHA 500 weaving systems offer weaving widths up to 5.3m, depending on the application.

A reed density of 400 – 480 pile points per metre can be chosen to meet the trend of low density, light weight and foldable carpets. This low density, combined with a much lower weft density, results in a higher production capacity, i.e. more metres of carpet per hour than on a velvet weaving machine, especially when you take the weaving width of around 5m into consideration.

Until recently, weavers of machine-woven used-look carpet lacked the means of creating real, flowing transitions that give the appearance of unevenly worn spots on the carpet.

But now, using Schönherr’s new binding technology Magic Weft Effect Duo (MWE Duo), designers can create designs that include “faded out” areas. This is done by weaving a gradual transition from 100% cut pile to a pure weft pattern, creating areas with a “thinned out” pile.

This binding technology also enables additional colour effects by combining up to 12 cut pile colours and up to 5 weft colours per gripper. This allows carpet designers to set extraordinary colour accents.

Modern, used-look carpets remain a strong trend, and they are no longer mainly limited to tone-on-tone designs. With MWE Duo, carpet mills can now efficiently weave them in high-contrast colour combinations – extending their product range and potentially serving an expanded market.