With the right partner to the top of the shoe fabric market

Several Corona waves, supply chain bottlenecks and unforeseen problems such as sudden power rationing in China have caused difficulties in the global textile market in recent years. The highly competitive shoe fabric market has been particularly affected by the difficulties.

Here, only those are successful who react quickly and flexibly meet customer requirements, combine quality with efficiency, hold their own in globalized markets and drive innovation. The Hua Yu Zheng Ying Group (Hua Yu) shows how this can be done. The RD 7/2-6 EN double needle bar raschel machine from KARL MAYER demonstrates what is needed to achieve this.

Hua Yu is a leading warp knitting company based in Jinjiang City, and is one of the first users of the high-performance RD machine. The RD 7/2-6 was launched in 2019 specifically to be more competitive in the shoe fabric market. Just two years later, the newcomer has established itself as the machine of choice among manufacturers worldwide.

Strengthening competitiveness with quality and efficiency

Hua Yu was founded in 1989 and produces warp knitted and knitted fabrics in a vertically integrated process chain with man-made fiber, yarn and textile production as well as finishing and dyeing. More than 400 modern warp knitting machines, including 170 double needle bar raschel machines from KARL MAYER, are running in the warp knitting mill.

The output is more than 20,000 t of functional textiles per year. This makes Hua Yu one of the leading companies in the warp knitting sector in China, and one of the largest producers of spacer fabrics in the country. The spacer textiles go mainly to the shoe market. This has been significantly overheated in recent years with full order books and short delivery times. Well thought-out strategies were needed for success.

Hua Yu has made its entire manufacturing chain more competitive and strengthened its core competitive advantages in terms of cost and size to respond quickly to external changes. It has also strengthened its technical base. “Besides, the key to our success also lies in heavy investment in KARL MAYER’s advanced machines of high speed and high yield to ensure quality and efficiency,” explains Mr. Su Chengyu, General Manager of Hua Yu Zheng Ying Group.

The RD 7/2-6 EN in particular perfects the balance between these two production factors, Hua Yu is confident. The quality of RD 7 goods is a real competitive advantage. “Of course, fabric produced with Karl Mayer’s machines feels smoother and more homogeneous and has clearer patterns, which are generally acknowledged in the industry,” said Mr. Yang Xiaoqing, Manufacturing Director of Warp Knitting Division of Hua Yu Zheng Ying Group.

Save manpower with more efficiency and flexibility

Hua Yu operates the RD 7/2-6 EN at up to 1,1000 rounds per minute and, thus, achieves significantly more output than before. The company’s capacities have increased by around 30%, according to Yang Xiaoqing. Hua Yu also benefits from the flexibility of the RD model. In the past, the production of warp knitted fabrics with different patterns required machines with different specifications and corresponding operating personnel.

This cost material and human resources. Equipped with seven guide bars and EN pattern drives for their electronic control, patterns of the most varied design can be produced on just one machine, thus, meeting the requirements of different applications. In addition, the patterns can be easily changed .

“With the RD7 from Karl Mayer, our production efficiency has been increased dramatically. Previously we had one operator on two machines, and now one operator can manage four to five machines. In addition, the company’s capacity has been increased by about 30%,” says Mr. Yang Xiaoqing.

In addition, the availability of the production equipment was significantly stabilized or improved. The machine failure rate fell from 6 to 3%, while operating efficiency increased from 80 to 90%.

With fast support to efficient operations

In addition to innovative machines, KARL MAYER offers to Hua Yu sophisticated after-sales solutions for an efficient internal operational procedure.

The innovative knitwear manufacturer is one of the first users of the RD 7/2-6 EN. If questions or problems arise, engineers are immediately on hand to monitor the required data and report back the monitoring results. If necessary, cooperation partners are also involved in problem finding on site. “KARL MAYER has service centers in China’s key warp knitting industrial clusters. It communicates with us in a timely manner, and responds quickly if there were any problems,” explains Yang Xiaoqing.

Hua Yu also cooperates with KARL MAYER’s Academy. The company’s in-house educational facility provides regular training on warp knitting technology and customized training at customers’ premises according to their specific technical requirements. Hua Yu wants to improve the technical skills of its staff and has already had them trained in a course. The first on-site training took place from 5 to 7 January and was very successful.

Co-innovation promotes the differentiation advantage

Technological innovation capability is Hua Yu’s core advantage in a competitive environment that is all about differentiation. The company attaches great importance to technological research and development capabilities. With an R&D team of around 200 employees and over 36 patented technologies, the company has won a variety of international sports brands such as SKECHERS, ASICS, PUMA, ANTA and LI-NING as long-term partners.

Hua Yu’s definition of innovation is broad.

It covers product innovations to meet the needs of the market as well as material innovation in line with the strategy of sustainable development. Innovations in the field of production equipment mainly concern the development and exploitation of machine functions and the exploration of completely new possibilities for fabric production together with the machine manufacturers. Among these, KARL MAYER is an important driving force.

Continue to grow with the right partner

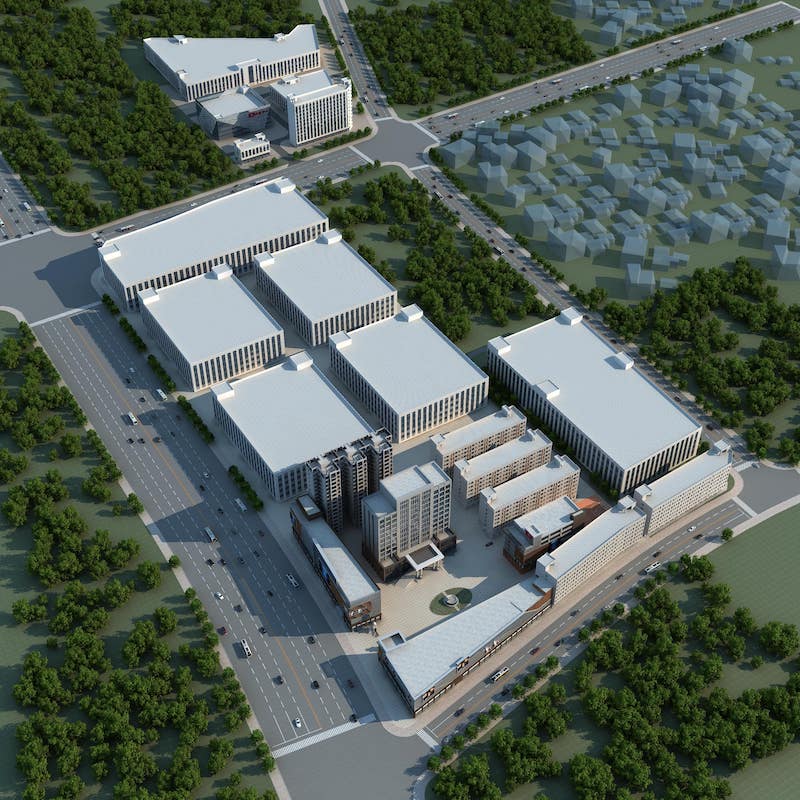

With its well-thought-out strategy, Hua Yu is still on the road to success. In order to expand and develop again, the company had just increased its investment by RMB 3.5 billion in 2019 for a new warp knitted fabric production project. The project will see the construction of a new factory covering an area of 170,000 m². As a partner of Hua Yu, KARL MAYER will also help the company improve its competitiveness in all areas with the new factory and lead it to greater success.