GSDCost will provide greater accuracy in Standard-Minute-Value (SMV) calculations ensuring production consistencies, improved line balancing and an enhanced customer experience

Coats Digital is pleased to announce that the global-leading jeans specialist, JD United (JDU Manufacturing Co.Ltd.) has adopted Coats Digital’s GSDCost solution to optimise its production efficiencies, improve costs and standardise its cost-to-make processes so that it can better align with changing customer expectations. GSDCost will provide accurate, detailed, scientific methods to initially improve method-time-cost efficiencies across three of JD United’s 31 production facilities, before being expanded out to other factories across China, Tanzania, Myanmar and Cambodia, later this year.

Established in 2005, JD United (JDU Manufacturing Co.Ltd.) became a subsidiary of Roohsing Group in 2017. Headquartered in Changzhou, China, JD United boasts 31 factories across China, Tanzania, Myanmar, and Cambodia and employs over 30,000 people. Specialising in all aspects of jeans production, JD United also produces woven jackets, knitted pyjamas, shirts and trousers for some of the world’s leading brands, including: Levis, Gap, GU, Primark, C&A, TCP and Gymboree. The company is committed to making high-value, quality products through innovative and revolutionary processes that foster more sustainable methods of production. As part of this programme, it has introduced low carbon manufacturing processes, greener energy workplaces and improved water treatment methods that make it a beacon for sustainable fashion manufacturing industry-wide.

Jessie Chen, Business Director, JD United, said: “Without standardised methods across our manufacturing units, our costings relied on inaccurate historical data and inconsistent time studies which often resulted in complex cost-to-make (CM) negotiations with customers. Coats Digital’s GSDCost solution is helping us to eradicate these challenges by enabling us to deploy accurate, scientific methods across our costing and capacity planning operations, so that we can offer reliable order quotes to customers, whilst simultaneously enhancing sewing methods and production line balancing at the same time. Coats Digital’s approach aligns perfectly with our sustainability objectives and its unique GSDCost solution will become a key driver in the advancement of our digital transformation strategy in the months ahead.”

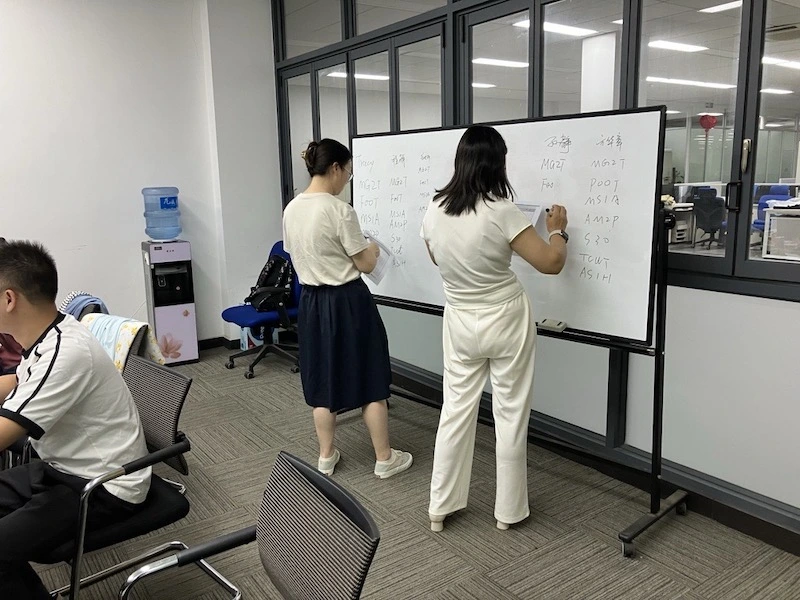

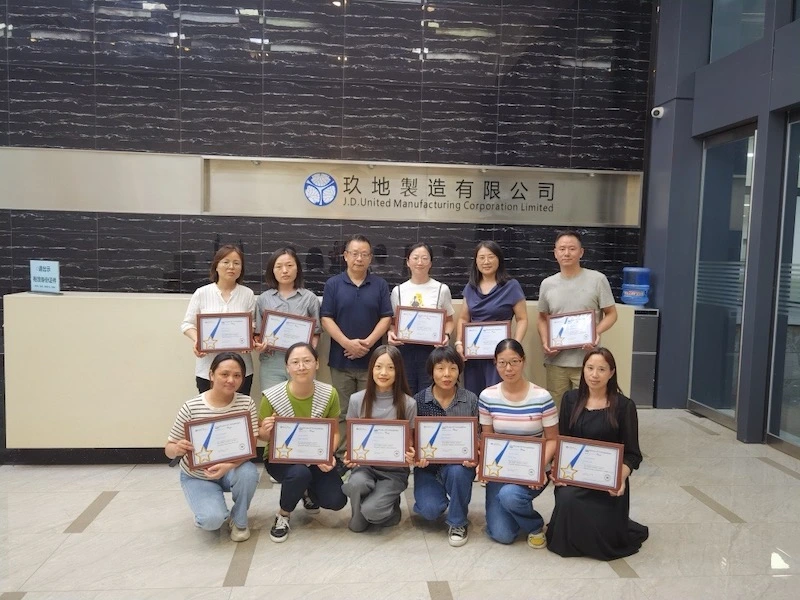

Tracy Li, Sales Manager, JD United said: ”The team at JD United has worked hard over the last few months to get to grips with the GSD methodology, and we are extremely grateful to the Coats Digital Training Team for its careful guidance and ongoing support – even dedicating its weekends to help get us successfully pass our initial assessments. We have accumulated the valuable knowledge we need to progress to the next level and are excited about putting GSDCost to good use in our technical department and on the factory floor so that we can improve efficiencies across the business.”

Coats Digital’s GSDCost method analysis and pre-determined times solution is widely acknowledged as the de-facto international standard across the sewn products industry. The solution supports a more collaborative, transparent and sustainable supply chain, in which brands and manufacturers establish and optimise ‘International Standard Time Benchmarks’ using standard motion codes and predetermined times. This use of a common language and standards supports accurate cost prediction, fact-based negotiation, and a more efficient garment manufacturing process, while concurrently delivering on CSR commitments.

。Liv Zhang, Sales Director (Greater China), Coats Digital, said: ”JD United is one of the world’s premier jeans manufacturer and we are delighted that it has partnered with Coats Digital to future-proof its business by optimising its cost-to-make (CM) production processes with GSDCost. The adoption of GSDCost is expected to result in substantial improvements across the business, ultimately boosting profits and ensuring seamless alignment with customer expectations. We look forward to supporting JD United with a successful GSDCost implementation and comprehensive GSD™ methodology training programme over the coming months to ensure it continues to retain its leading position on the global stage.”