Interview with Saurer Group / By: Kohan Textile Journal

Saurer Spinning Solutions offers high-quality, technologically advanced, and customer-specific automated solutions for staple fibre processing from bale to yarn. In this section, we have an interview with one of the most important textile machinery manufacturers in the world, Saurer Company, which we hope will be noticed by the readers and followers of Kohan Textile Journal all over the world.

1- Saurer has a wide range of products from pre-spinning machinery to Automation and mill management, please share with us the latest innovations and products from Saurer.

Saurer Technologies specializes in intelligent and economical twisting and cabling machines for tire cord, carpet, staple fiber, glass filament, and industrial yarns, which allow customers to adapt flexibly to dynamic market requirements.

Currently, the main trends in the market are automation, digitalization, and recycling. Digitalization has revolutionized traditional services such as site visits, in-person training, and machine troubleshooting.

Automation within the single machine, between the machines, and on the complete mill level has become the new standard. Aligned with Saurer’s vision as a solution provider, the Senses mill management system allows customers to connect all their Saurer and third-party machines in one system.

The Autocoro 10 is perfectly tailored to sustainable raw materials, especially those that consist largely of recycled and regenerated materials.

With SynchroPiecing 36, the Autocoro 10 offers a 50% higher piecing capacity than the previous generation, which ensures particularly high productivity, especially when regenerated material is being processed. It has a market share of more than 90% with more than 1 million spinning units sold worldwide.

Since the introduction of the air-spinning machine, Saurer now is the only textile machinery manufacturer to offer machinery for all five end-spinning applications: ring, compact, rotor, air, and worsted spinning. Saurer is traditionally strong in the Middle East region with its worsted ring-/compact-spinning machine Z 451 for wool and acrylic yarns.

Saurer Twisting Solutions offers remote service to allow the experts to access a fully digital read-out of the error log, which allows them to identify any issues. The Saurer Academy offers a wide range of online and web training courses for machine operators. Customers can book classroom and live web-based training courses.

2- Saurer is a leading manufacturer of high efficiency, high yield and high-quality blowroom machinery in the world, please let us know more about your blowroom production facilities and the latest technologies and innovations for that.

Saurer pre-spinning is the foundation of the Zinser ring-spinning and Schlafhorst open-end systems. The flexible portfolio offers the right solutions for the preparation of all kinds of fibres for the subsequent processes. The right combination of blowroom and carding machinery ensures excellent fibre utilisation and sliver quality for high efficiency and yarn quality in spinning.

Saurer offers automatic and reciprocating bale pluckers, enabling customers to adapt their blowroom according to their individual needs. Booth bale pluckers are suitable for all kinds of materials with a fibre length below 76 mm. Our engineering department offers different configurations for the blowroom depending on the raw material used.

The new Autocard was developed to create further value in the fibre preparation chain. The machine’s higher carding area means 18% higher output and an even cleaner sliver. It also features LED lights for intelligent operator guidance. Can changes are carried out during full production without slowing down the speed of sliver delivery.

Complete lines with Saurer pre-spinning line together with the fully automated Autocoro rotor spinning machines have already been installed in several markets. The combination offers excellent ROI and low spinning costs for all textile applications, for conventional cotton spinning as well as for the processing of sustainable fibres.

3- Saurer participates in the most important trade shows all around the world in 2022 like ITM Istanbul or JEC World. How do you feel to meet again customers and potential clients face to face after a long Coronavirus pandemic period?

We hope that the easing pandemic situation will allow some of the large exhibitions to take place to live in 2022, enabling more direct meetings again and presenting our latest innovations. We very much look forward to meeting our customers in person again. The pandemic has not only caused exhibitions to be postponed but also made traveling difficult. Both, our customers and we ourselves feel that digital meetings cannot replace personal meetings.

4- How do you evaluate the textile industry in the Middle East and Africa region?

Near- and on-shoring has been discussed on several occasions over the years. The current freight rates for containers from Asia to Europe are adding urgency to these discussions. A certain re-location of production also in the Middle East and African regions is expected.

Further, several African countries export cotton and this offers an opportunity for further value addition in the country and on the continent. We have been expecting the African textile industry to grow and diversify even more – maybe the post-pandemic opportunities will further support this development. We consider developments and opportunities within the region from the viewpoint of the spinning industry.

5- How do you evaluate new investments in the spinning sector in the Middle East and CIS especially Turkey, Egypt, and Uzbekistan?

The new investments are triggered both by near/re-shoring as well as the requirements to increase value add in the textile value chain inside the countries. Turkey is preparing to take over some of the Asian market shares and the investments over the past years have been considerable.

We are pleased to see the modernisation of the spinning industry in this region. Several of Saurer’s key customers come from this region and many of our most advanced automated high-speed and high-efficiency installations have been and still are being delivered to the region.

6- Saurer developed a powerful customer portal to support clients all around the world easily and fast, could you please explain more about Secos? How does it work and what are the benefits for manufacturers?

The Secos – Saurer Customer Portal is more than just an e-shop for Saurer original parts. With the updated version of the portal, it is easier for customers to find original parts – with photo uploads, customers can quickly identify the required original part they need.

In the user’s Secos account, all machine-related manuals and technical documentation for their machines are saved for quick reference in case of questions on operation and maintenance. Like Senses, Secos can be accessed anytime, from any mobile device.

Saurer Twisting Solutions experts can access a fully digital read-out of the machine log. They can also adjust machine control settings, update software and do diagnostics checks of any hardware defects as well as check CPU usage, energy consumption, and machine temperature. This means getting the customer’s machine running at optimal capacity faster with less downtime.

7- Sustainability and energy consumption are two main factors for textile machinery manufacturers for many years, what is Saurer Group’s sustainability policy, and your latest innovation and achievement in this sector?

With the E3 philosophy, Saurer ensures that each machine new generation uses less energy, supports customers to save resources, and offers improved working conditions and optimised material flow. As an environmentally conscious company, we aim to make our products as energy-efficient as possible.

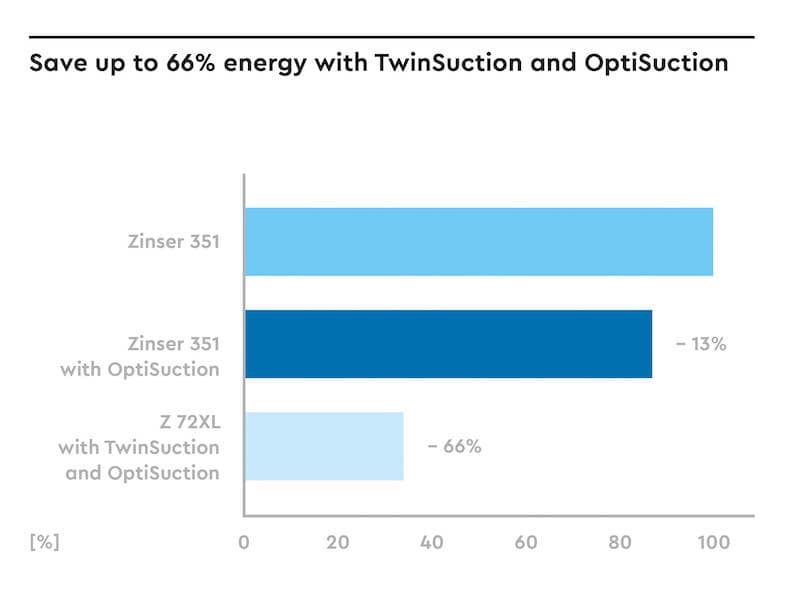

Aside from decreasing our clients’ energy costs, this approach also allows our customers to position their offerings as sustainable – a necessity today given the climate challenges the world faces. For example, the Saurer twisting machine CompactTwister offers up to 40% energy saving by optimised spindle technology, and the Saurer ring/compact spinning machine Z 72XL offers up to 66% energy on suction thanks to Twinsuction and Optisuction compared to previous models.

Saurer is in an excellent position to process recycled fibres with the market leader Autocoro in the fully automated market segment and the BD product series in the semi-automated market segment.

We already have a large number of customers worldwide in recycling and have deep inside knowledge on how to improve various processes within the mill. Our textile laboratory in Übach-Palenberg, Germany, is continuously proving consulting services to customers on how to improve efficiency and yarn quality for both ring- and rotor-spinning processes when spinning recycled fibres. Our pre-spinning portfolio also offers solutions for recycled fibres.

pls send ur journal on a regular basis, it is really useful for our textile factory. thank you