Interview with Dilo Group – Mr J. P. Dilo by Middle East Textile Journal

DiloGroup is a leading supplier of industrial lines for the production of nonwovens with a special emphasis on needling lines manufactured in Germany by the members DiloTemafa, DiloSpinnbau and DiloMachines.

1. Could you please let us know more about DiloGroup and products, goals and success story?

Dilo Group is a leading supplier of industrial lines for the production of nonwovens with a special emphasis on needling lines manufactured in Germany by the members DiloTemafa, DiloSpinnbau and DiloMachines.

Lines for thermobonded or water-entangled products we offer through cooperation with partners. Our leading position includes technological leadership as far as line production rates, line efficiency and end-product quality are concerned.

The machines made in Germany are renowned for their reliability over decades of production, supported worldwide by spare parts supply and quality service through well-trained and experienced technicians. Computer controls and operating systems assure a high degree of automatization and ease of operation.

Besides needling lines a major area of our worldwide deliveries are web forming systems through highspeed carding with large working width and cross lapping lines in conjunction with the water entanglement or thermobonding technologies.

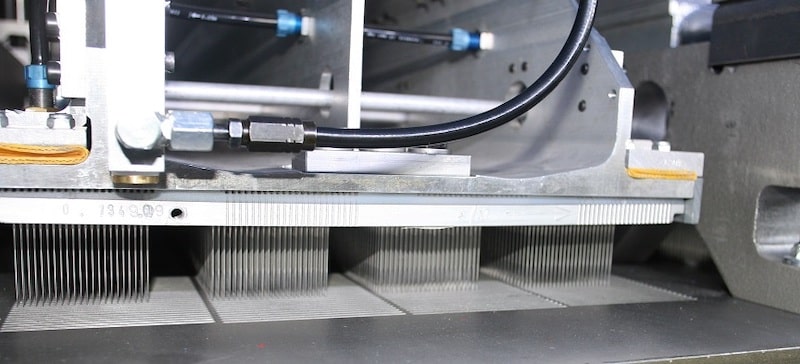

Dilo is known for a high degree of innovation in new processes and machinery. Lately intensive needling is developed further to reduce the amount of energy needed in nonwoven production. At the same time highly sophisticated systems have reduced the amount of fibre material needed to arrive at the required endproduct quality. Our goal is to provide nonwoven staple fibre processing equipment with low energy consumption and a high degree of fibre savings.

2. What do you think about the Middle East and Africa Nonwoven machinery market and it’s potential?

The machinery market in the Middle East and Africa should gain a much higher potential in the future, if the general development is considered with growing populations and steady development in the societies where the so-called middle class is requiring a higher quality of living standard. In this regard, nonwovens play a major role, particularly in the field of medical and hygienic products as well as in the building and construction industry for better infrastructure.

3. Do you have export to the region? Which countries in the Middle East and Africa is your main destination?

Dilo Group traditionally exports to this region where in recent years the main focus has been Turkey and countries in Northern Africa like Morocco, Algeria, Tunisia or Egypt.

In the whole region of the Middle East and Northern Africa, our markets are considered to have high growth potential. So far, they have a share of our production of a total of ca. 5 %.

4. How do you evaluate the nonwoven machinery industry in Germany and globally? What kind of innovation is expected in nonwoven industry and your products?

The nonwoven industry is highly successful within Germany and of course, Europe as a whole with a good growth rate at normal times. The same is true to an even higher degree in Asia and also the USA. With regard to innovation Dilo focuses, as said before, on the nonwoven process with the aim of reducing fibre consumption and energy.

In this field our “Micropunch” development or the “3D-Lofter” for 3D-shaped moulded car parts for example or for inclusion in garment and shoe production is seen as a high potential.

6. What are the major barriers in the textile and nonwoven trade in the region?

Major barriers for improved development are political issues with the involvement of the military, trade barriers because of growing risks through unsettled disputes among societies and governments in the region and abroad.

Dilo takes part in all major exhibitions for nonwoven machinery and products. To name the most important ones, ITMA, INDEX, Techtextil and many others like ITM, SINCE, CINTE, ITMA Asia. Our next participations will be at CINTE in Shanghai from September 2 – 4 and at Nonwoven Tech Asia in Delhi, India from October 8 – 10, 2020.