How AQUARIA® and AIRO® technologies are setting new quality and efficiency standards

Industry Overview

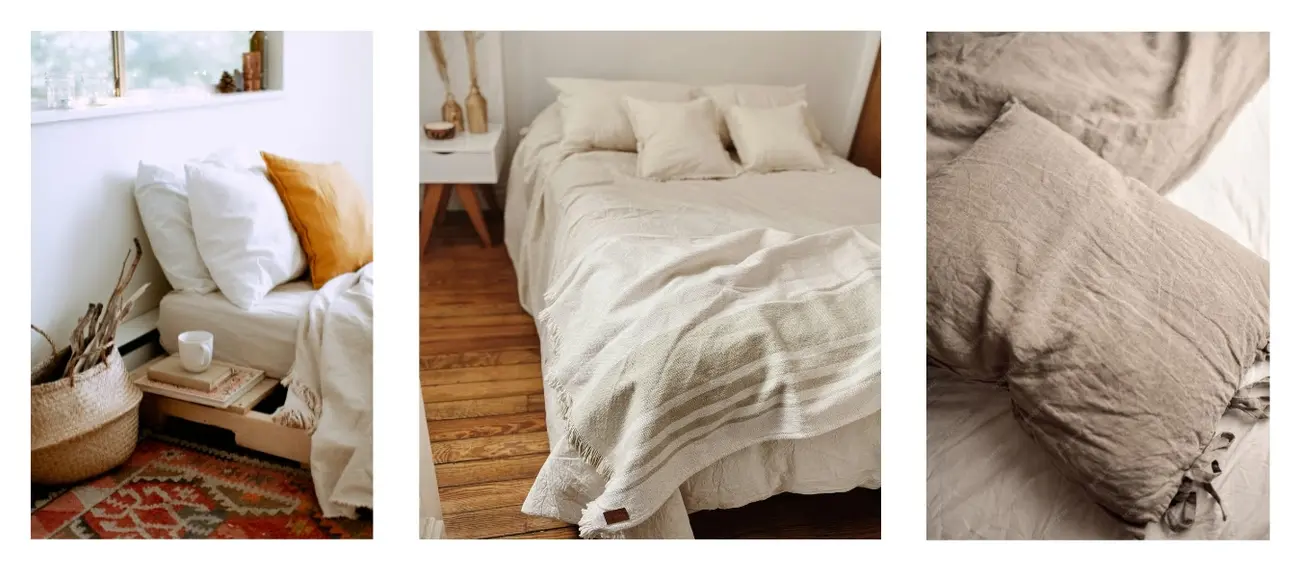

The bed linen industry is undergoing a significant transformation, driven by a growing demand for superior quality sheets that combine durability with exceptional comfort. As consumer preferences evolve toward softer, more innovative, and sustainable products, manufacturers face the challenge of meeting these expectations while maintaining production efficiency.

Traditional Limitations

Traditional production processes, while reliable, have shown notable limitations, particularly when dealing with double-width fabrics commonly used in sheet production. These conventional systems give the fabric a classic but flat appearance.

AIRO® Technology Revolution

Innovative technologies like AIRO®24 and AIRO®24 DUETTO are transforming the landscape of bed linen finishing. These advanced continuous open-width drying systems specifically handle double-width fabrics for sheets, providing superior dimensional stability through their unique mechanical action.

The mechanical action of AIRO®24 and AIRO®24 DUETTO achieves what traditional methods have always struggled with: simultaneous fabric stabilization and softening in a single pass, delivering an exceptionally soft hand feel while maintaining perfect dimensional stability, a combination that sets new standards in bed linen quality.

Dual Benefits of AIRO® Systems

This dual benefit offered by AIRO® systems addresses one of the most persistent challenges in bed linen production, where achieving both stability and softness often required compromises in traditional processes. The controlled mechanical action ensures that the fabric maintains its structural integrity while developing the soft, luxurious hand that consumers expect from high-quality bed linens.

AQUARIA® Innovation

For preparation and pre-treatment processes, AQUARIA® technology represents a significant advancement in bed linen production. The system enables efficient fibrillation and enzymatic treatments with substantially reduced water and energy consumption compared to conventional batch processes.

Efficiency and Quality

The system’s ability to process fabrics efficiently while maintaining high-quality standards represents a significant advancement in bed linen production. The reduced resource consumption and elimination of harsh chemicals align with the industry’s growing demands for more sustainable production methods. Furthermore, the improved process control leads to more consistent product quality, reducing waste and the need for reworking.

As the industry evolves, these technologies allow manufacturers to meet growing consumer demands for superior bed linens while adhering to increasingly stringent environmental standards. The combination of innovations in mechanical and chemical processes provides a complete solution to traditional challenges in bed linen production, setting new standards for quality, efficiency, and sustainability in the industry.