Interview with Danna Drion, Senior Marketing Manager EMEA, and Yumi Taguchi, Area Sales Manager

By: Kohan Textile Journal

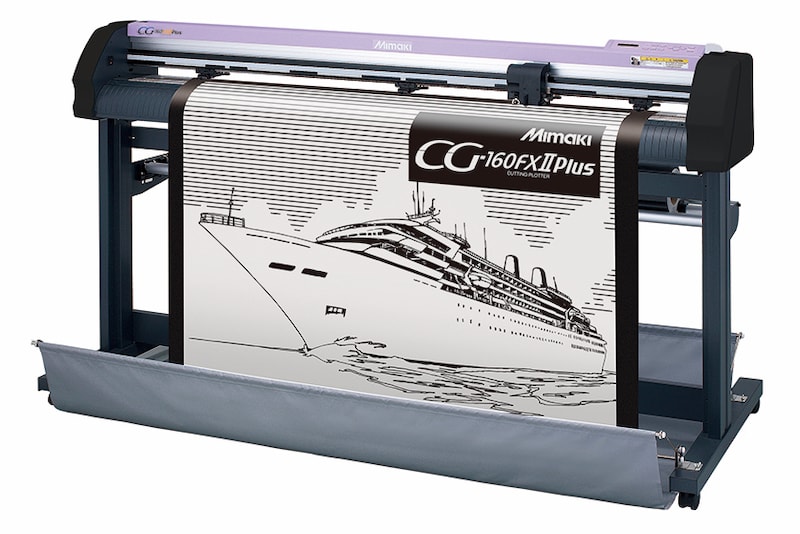

Founded in Japan in 1975, Mimaki is a leading manufacturer of wide-format inkjet printers and high-precision cutting plotters for the sign/graphics, industrial, textile/apparel and 3D markets. Mimaki develops the complete product range for each sector, from hardware and software to consumable items, such as inks and cutting blades.

1. Could you please let us know more about MIMAKI Group, its products and services, goals and success story?

Danna Drion: Mimaki first started with small machines, printing from one to five square meters an hour, and from that created a whole dealer network, forming the foundation of the market. Today, there are thousands of installations across EMEA and in a variety of markets—not only in textile, but also sign graphics, industrial and 3D.

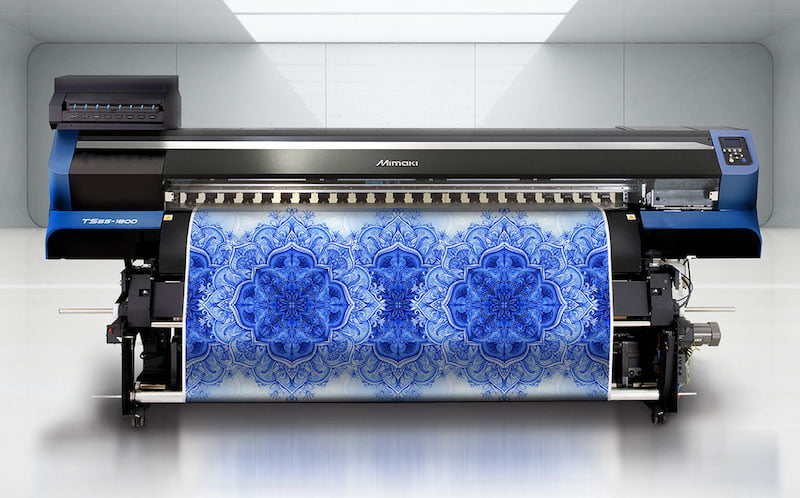

In the textile industry, we started back in the 1990s with paper transfer and direct-to-textile printers. Now, we offer the most comprehensive textile solution portfolio. This includes a wide range of textile printers for the entry and mid-market segments, a game-changing high-volume industrial textile printer, and a range of textile pre- and post-treatment machines.

Mimaki values innovation and quality – both are key to our vision. There are many standard printers in the market, and so we go that extra mile by, for example, adding intelligent features on our machines, which we call Mimaki Core Technologies.

Some of these are MAPS (Mimaki Advanced Pass System), which can reduce banding even at high speeds, and Nozzle Check Unit (NCU) and Nozzle Recovery System (NRS), which can detect defective nozzles and switch them with working nozzles so that the printer can continue printing with good quality until a technician arrives to do the necessary maintenance.

2. As a global leader company in Digital printing, what do you think about the textile industry situation globally in this hard time and what is your prediction for the post Corona Period?

Danna Drion: Like many other sectors, the textile industry has been strongly hit by the Coronavirus pandemic at a global level and, with the current ever-changing situation, it is certainly difficult to predict the exact outcome at this point in time. Having said that, we have seen printing textile companies bounce back from these adversities at an astonishing rate, by adapting their operations and making their businesses increasingly more service driven.

And here is where digital printing is beneficial, as it enables textile companies to ensure their customers get efficient and on-demand services: looking at the workflow as a whole, digital printing can provide faster delivery times, customisation and makes products easier to test, which is exactly what is in high demand in the textile market.

Looking at the future of the textile industry, I expect to see several significant changes in the way businesses are run. Just to give a couple of examples, due to COVID-19 impacting overseas imports, a lot of fashion and apparel brands are considering moving production back to local areas, which will most probably lead to local production methods becoming more competitive over time.

Similarly, the current situation has encouraged those companies who had not yet made the jump to online, to at least give it a go. In fact, not only are webshops accessible 24/7 and from everywhere, but they also make the processes both quick and easy for the customer, as well as give immediate access to personalisation.

3. In the last decade the textile printing industry experienced extraordinary growth, how do you evaluate the future of textile printing?

Danna Drion: Only a small percentage of today’s global textile production is done using digital print technology. In fact, it’s estimated that only around 5% of today’s worldwide textile production is digital, with the rest being printed using conventional analogue techniques. This, in itself, presents a huge window of opportunity for print service providers to expand with digital textile print technology.

Therefore, we can certainly expect the digital textile print industry to keep growing. Digital printing will prove key to facilitating the growing demand for shorter runs, faster delivery and more customised or personalised production of textiles, perfectly matching the current textile market requirements.

This is certainly the case for fast fashion, a dynamic market segment requiring quick production schedules at a low price, as well as for interior décor, where there is an increasing demand for customised home textiles, such as curtains or cushions. In addition, building on the feedback from our customers, I also expect to see interesting growth rate in technical textiles.

Despite the current circumstances, digital textile printing is likely to continue to increase and unlock new application opportunities.

4. What do you think about the Middle East and Africa textile market and it’s potentials?

Yumi Taguchi: The digital textile printing market in the Middle East and Africa definitely has huge potential that is relatively untapped. Sublimation printing is currently very popular in the MENA region. In particular, the market at large is focusing on the sportswear sector. Despite being less popular than sublimation printing, direct-to-textile printing technology is also growing in the areas of home textile and fashion apparel.

5. Do you have export to the MENA region? Which countries in the Middle East and Africa are your main destination? How big is your market in the Middle East and Africa?

Yumi Taguchi: Yes, Mimaki works with a vast global network consisting of long-established partners worldwide. No matter which country you are located in, we have a partner that can support your business from start to finish. Our top countries for textile in the MENA region are Pakistan and Egypt.

6. What are your strategies for expanding your market in MENA region in future?

Yumi Taguchi: Well, we need to differentiate our strategy depending on the specific country/market we target. Having said that, generally speaking, our leading technology in the area is sublimation printing, as we offer top-quality, cost-effective printing platforms that meet the requirements of local demand for both quality and volumes.

In particular, our TS300P-1800 dye sublimation printer has been very popular in the region, especially in Egypt, over the last years. Building on the evolution of the market, we are currently focusing on our flagship TS55-1800 printer, which is ideal for those companies in need of higher production volumes.

For those who are curious about the TS55-1800 dye sublimation printer, we are offering a free sample kit so that you can check out the machine’s print quality up-close. We will also hold a free, interactive webinar in September, during which you can ask any question about this machine. So I would like to encourage the readers to check out our website and social media to request for a sample kit or register to our webinar.

7. Normally to how many exhibitions do you participate annually and to which ones? Your next participation is in which country?

Yumi Taguchi: Under normal circumstances, Mimaki Europe participates in all major tradeshows in relevant markets, including international events such as ITMA and FESPA Global Print Expo and other regional events.

Our Mimaki partners are the ones participating in various tradeshows within the MENA region and Mimaki Europe supports them with their presence at these events. Some of our partners participate in Stitch & Tex Expo in Cairo (Egypt), FESPA Africa, Digi Sign Africa Cairo, and more.

Danna Drion: I would add that faced with the outbreak of COVID-19, earlier this year we had to quickly change our event policy in order to ensure we could maintain communications with our customers and support them through this difficult time.

Therefore, we have set up a series of virtual events – ranging from the Mimaki Virtual Print Festival in March and April, to the ongoing Mimaki Live Series which includes technology-focused webinars run by our local partners – to help keep the industry connected and thriving. In fact, our virtual Mimaki Live events have been exploring ways in which printers, whether they specialise in textiles, large format, 3D or signage, can keep their business going and even be reinvigorated during these trying months.

Looking ahead, we currently plan to run other virtual events until the end of 2020, but we hope to also be exhibiting at tradeshow events again in 2021.