▶︎ In Brief: Marzoli’s GALILEO C702 carding machine redefines spinning performance with a 3.74 m² carding surface, advanced cylinder design, up to 270 kg/h productivity, and Industry 4.0 integration. It delivers high-quality sliver, energy efficiency, and digital intelligence for modern textile mills.

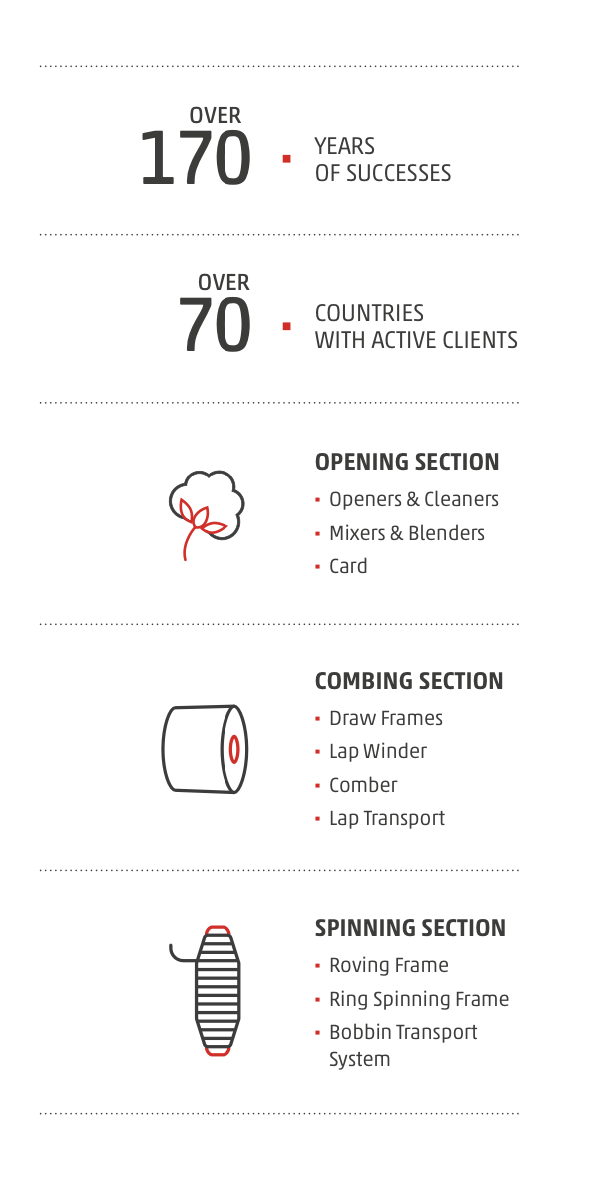

In the landscape of modern spinning technology, carding remains the cornerstone for quality yarn production. The GALILEO C702 carding machine from Marzoli, one of the few European manufacturers of complete short-staple spinning lines, exemplifies technical excellence and innovative design.

Here’s an in-depth look at five core strengths of the C702 carding section that every mill manager and textile engineer should know.

1. Engineered for High-Quality Carding Output

Carding is vital to achieving uniform, clean, and strong yarns. The GALILEO C702 is purpose-built to handle the increasingly variable and lower-grade raw materials found in today’s market. With a carding angle of 284° and an effective carding surface of 3.74 m², it ensures intensive fiber opening and cleaning. This directly translates into more homogeneous and resilient yarns and better performance across downstream processes.

2. Optimized Cylinder Geometry and Carding Surface

At the heart of the C702 is a main cylinder with a 1006 mm diameter, delivering high efficiency and greater carding action per rotation. The larger diameter provides a more stable mechanical process, reduces vibrations, and enhances longevity. Combined with a large working surface and smart clothing design, the machine optimizes fiber individualization while reducing waste.

3. High Productivity with Energy Savings

With a maximum production capacity of up to 270 kg/h, the C702 is designed for high-output environments. Its compact design, fewer moving parts, and efficient suction systems contribute to lower energy consumption per kilogram of sliver. Marzoli has engineered this model for reduced wear and tear, minimizing maintenance while delivering excellent return on investment.

4. Flexibility and Modular Design for All Fiber Types

Whether working with cotton, synthetic fibers, or blends, the C702 is adaptable to different raw materials and end-use applications. The machine features customizable configurations for the pre-carding, main carding, and post-carding zones, with various accessories including doffer systems, waste suction units, and web extractors. This modularity enables precise control of trash removal and sliver quality, even under demanding conditions.

5. Integrated Drafting System and Digital Intelligence

One of the standout features is the optional integrated drafting system, allowing the machine to directly feed rotor spinning frames, thus eliminating the need for additional draw frames in some configurations. This reduces footprint, energy use, and production complexity.

Even more impressive is the C702’s compatibility with Marzoli’s Industry 4.0 platforms:

- MRM (Marzoli Remote Maintenance): Enables predictive maintenance, process monitoring, and diagnostics.

- YarNet: Offers plant-wide data integration, helping operators make informed decisions in real time.

These platforms provide valuable KPIs such as waste percentages, production efficiency, and fiber quality metrics, contributing to a fully digitalized and optimized spinning mill.

Conclusion: A Future-Ready Carding System

The GALILEO C702 is not just a carding machine—it’s a robust and intelligent component of Marzoli’s end-to-end spinning solutions. Its combination of precision mechanics, digital connectivity, and flexibility empowers textile manufacturers to maintain high quality standards, even in the face of fluctuating raw material availability.

With Marzoli’s 170+ years of heritage and ongoing innovation under the Camozzi Group, the C702 represents the convergence of tradition and future-forward technology in spinning.

Do you have questions about carding, digitalization, or optimizing your spinning process?

We invite you to share your thoughts in the comment section below and join the conversation about the next generation of textile production.