PT Rainbow Indah Carpet has in- vested into a COLARIS digital carpet print line from ZIMMER AUSTRIA. “Rainbow Carpet” a leading carpet manufacturer in Indonesia, having capabilities of tufted broadloom carpets, PVC carpet tiles, Axminster and CHROMOJET printed carpets.

After the successful installation of a CHROMOJET printer and a ZIMMER PVC carpet tile back coating line, Rainbow Carpet put a COLARIS carpet print line into operation recently. With this latest installation we have added the possibility to produce high resolution digital printed carpets, rugs and tiles from PA tufted base material, claims Mr. Bhagwan Bharwani, General Manager of Rainbow Carpet.

The strength of PT Rainbow Indah Carpet is the supply of high-end carpet solutions for the residential, office, in-store and hospitality segment. Their mission is to provide a valuable service to the high-end flooring segment with utmost flexibility. Offering quality products with a tremendous saving needs a flexible and economic setup.

Evaluating various options for an economic solution for their expansion plan has let them to invest into a COLARIS digital carpet print line. Best value for money and the technology offered where the key points to place the order with ZIMMER AUSTRIA, says Mr. Bhagwan Bharwani.

What makes this installation unique?

• Most compact and cost-efficient print line in 4200 mm width in the market

• Production capacity of up to 720 m²/h

• Compact print line with a total length of approx. 35m incl. loop steamer with fixation booster system for wash free production – washing on demand only

• Ready for coated and uncoated carpet

• Pile weight range from 200 g/m² loop-pile to 1500 g/m² heat-set contract cut-pile

For the ambitious targets of Rainbow Indah Carpet, with the required flexibility and economic set-up ZIMMER AUSTRIA additionally was challenged by limited space available for the installation.

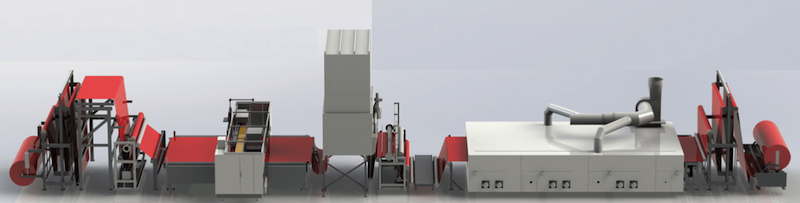

To keep the line short, we installed a vertical steamer with about 15 m content and integrated a Fixation booster system. This gives best fixation in a very compact form. The line layout with un-rolling, accumulator, center guiding, carpet pre-conditioner, COLARIS printer, loop steamer with fixation booster system, spray washer and vacuum, foam applicator, horizontal dryer, followed by an accumulator and final roll-up system has convinced the customer to solve all his needs at most cost-efficient layout.

The order was placed the end of 2018 and started up end of 2019. Since then it is in daily production.

TECHNICAL DATA:

Max. fabric width: 4200 mm / roll-to-roll Pre-conditioning: spray or padding with vacuum extraction

Printer model: COLARIS.48/24-4200

Ink type: acid – for polyamide, wool

Steamer type: loop steamer

Post print washing: spray washing with vacuum extraction

Drying: direct gas heated dryer