ZIMMER AUSTRIA has years of experience in conventional camouflage printing. Being also manufacturer of digital inkjet printing machinery, the logical consequence is that both technologies are combined for a future-oriented camouflage printing process.

Resulting from intensive research and development we can offer a digital printing solution that matches the requirements for most internationally operating forces and security agencies.

COLARIS camouflage printing system offers perfect color adjustment with additional IR reflectance control through imitation of specific reflectance characteristics.

Highlights

fast color matching

digital IR reflectance control

unlimited number of colors and shades

unlimited repeat size

no minimum order quantity

environmentally sustainable process

HIGH PERFORMANCE MILITARY TEXTILES

Textiles used for military applications are designed for heavy duty performance under demanding conditions.

They need to perform in different terrains, under severe climatical conditions and within extremely tough operational environments. All gear is designed to protect military force or security personnel and equipment. Military textile printing is an extremely challenging task.

Depending on the final application, the fiber and material compositions are selected.

Criteria can be:

- mechanical strength, light,wash, crock fastness and price

- polyamide, polyester, cotton, regenerated celluose fiber, aramid and other special fibers are used to match different requirements

- twill, ripstop, plain weave, different kinds of knits and many more constructions are used in military camouflage fabrics

DYE FAMILIES

Depending on fabric composition, different dyes are used for printing.

- polyamide: metal-complex and acid dye inks

- polyester: disperse inks

- cotton and regenerated cellulose fiber: Jettex® VAT inks

- substrates from various fiber blends: pigment inks

PRINT PROCESS

In most cases, a 3-stage process is required.

1. pre-coating with drying to avoid excessive ink migration

2. printing with drying and HT fixation for IRR carbon black

3. fixation process depending on applied ink type

IRR control

PATTERNS AND THEIR USE

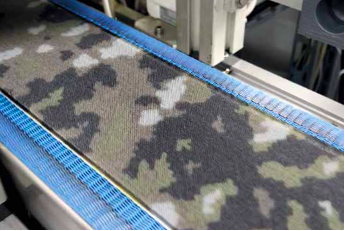

Designs may range from a simple 3 color design to highly sophisticated multi-color patterns including gradient colors. Each military force or security firm uses a set of various specific designs and color combinations.

COLOR FASTNESS

Camouflage prints require the highest industrial standards. Depending on the intended use of the printed substrate, fastness requirements may vary.

Nets or tents have different needs compared with sleeping bags, uniforms, ponchos or carrying systems. Fibers play a major role and are the limit for the achievable fastness level. Each fiber used in a textile substrate requires a specific ink.

COLOR MATCHING

Digital color matching takes few minutes only, whereas matching of colors in conventional printing is time-consuming. Color matching and IRR control is enabled in a very efficient, new way. Thus, the advantages and boundaries of digital printing technology come to full effect, enabling quick turnaround from sampling into production.”

COLORS AND THEIR NEEDS

For military applications, colors and shades are chosen by their dominance in the environment of a potential combat area. They are a selection of sand and stony shades, leaves, bark and soil, etc. mainly covered by shades of black, grey, brown, olive, green, blue and others.

IRR CONTROL

The patterns and colors selected are relatively easy to match for daylight camouflage. More difficult is hiding of visibility in twilight or at full night darkness.

Through a night vision device, colors without IRR control appear as light grey. By adjusting the reflectance for each individual color as close as possible to the natural colors of leaves, bark, soil, sand, stone, etc., the detection of an object becomes almost impossible.

ZIMMER has developed a technology for a realistic simulation of a print when seen through a night vision device. A specifically designed workflow allows to match the L*a*b and IRR requirewith IRR Control ments and to control the inkjet system.

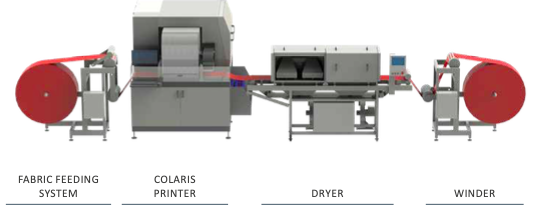

COLARIS PRINTER

COLARIS is a versatile, industrial inkjet printing system, offering a wide range of applications. The print lines are built in a modular system and can be adapted to different needs of substrates and ink classes as well as capacity requirements.

TECHNICAL DATA

print width: 2200 and 3200 mm

print speed: up to 1200 m²/h

number of colors:

– up to 12 color groups

– up to 3 ink classes at 4 colors each

– or up to 2 ink classes at up to 6 colors

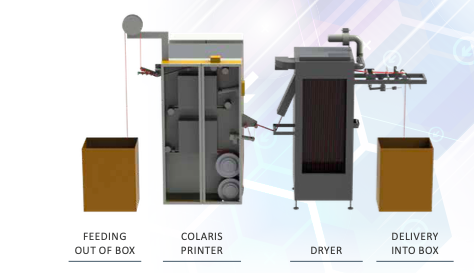

COLARIS-NF SINGLE

The COLARIS-NF Single is a single pass, one side printing solution for webbings with 100 mm (4“) or 300 mm (11,8“) width. Webbings are common in military applications. Rigid belts for carrying systems as well as hook and loop strapping for quick fixation are very common products.

TECHNICAL DATA

print width: available at 100 mm (4“) or 300 mm (11,8“)

print speed: up to 50 m/min

Number of colors: up to 12 process colors

COLARIS-NF MULTI

The COLARIS-NF Multi is a single pass doubleside pinter for webbings with a width of up to 65 mm (2,5“). The COLARIS-NF Multi is the only printer in the market that can print front and backside of a web in a single pass. It is possible to print images in mirrored setup (weaving effect), without mirroring or one-side printing and backside application of a single solid color (digital dyeing).

TECHNICAL DATA

print width: available at 65 mm (2,5“)

print speed: up to 50 m/min

number of colors: up to 8 process colors