There are several new trends arising that make good use of advanced technologies which help to create woollen fabrics with amazing designs. Like coats and oversized cardigans with different weights.

While the diverse weight of woollen fabrics can cause difficulties during the textile finishing process, there are two machines made by Biancalani which offer new solutions.

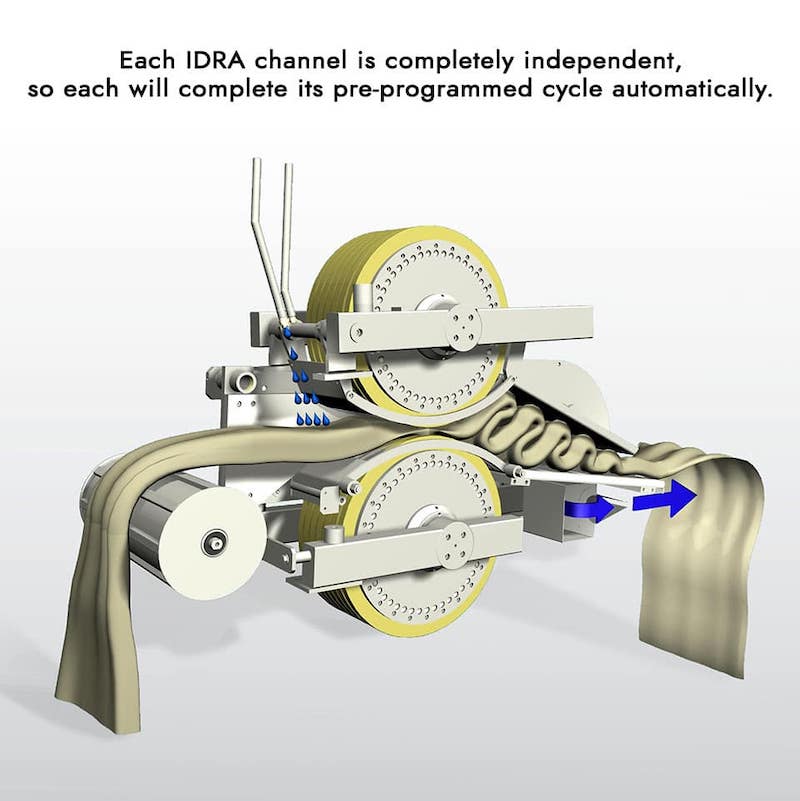

One is called IDRA which is a combined modular washing and milling machine. This textile finishing machine with independent channels is designed to independently wash and mill woollen fabrics of different compositions

In the different IDRA channels, it is possible to load fabrics of varying composition, width and weight because the parameters used in each individual channel do not influence those of the others.

The greatest innovation is that each channel is completely independent, so each will complete its pre-programmed cycle automatically, while the others will continue to operate until their own milling cycle reaches its conclusion, allowing the milling of woollen fabrics with different weights independently.

The other machinery is MILLA a combined washing and milling machine. Both types of machinery created by Biancalani Textile Machinery are milestones of woollen fabric manufacturing. In this short video we show and explain you how our combined washing and milling machine MILLA works.

IDRA and MILLA are equipped with an air-jet device – patented and constantly innovated by Biancalani – that ensures the absence of creases and permanent strains in the fabric. In addition to this, milling time has been significantly reduced with special attention to limit consumption and thus preserving the environment.

Furthermore, IDRA & MILLA can be used both for heavy fabrics and lightweight articles manufacturing, ensuring a deep milling action on the first and a safe one on delicate fabrics. Obviously, the milling step is at the core of wool manufacturing and thus of what we see in big brand stores. Nowadays, brands are attentive to details and their motto is “always demand the best and never settle for anything less”.

That’s because end customers are well informed, they read labels and know what they want from a brand. In order to meet their requests, everyday more manufacturers are choosing Biancalani Textile Machinery. Amazing results, best quality, sustainability. Those are the characteristics of woollen fabrics manufactured with IDRA and MILLA.