Economic efficiency, sustainability and climate-friendly yarn production – the Autocoro 11 plays in the top class in all areas. It spins sustainable raw materials with ease and is the spinning machine with the lowest energy consumption on the market.

The cost of yarn production is rising worldwide. The spinning mills have only a limited influence on this development, as too many factors play a role: Economic, political and financial, to name but a few. The best strategy for spinning is therefore to avoid costs. When it comes to the energy-saving production of yarns, there is no way around automatic rotor spinning. No spinning method requires less energy in the process to produce a ready-to-sell yarn.

After raw materials, energy is the second largest cost item in the automatic rotor spinning mill. Minimising costs here directly increases the profitability of the spinning mills. The Autocoro 11 automatic rotor spinning machine is a champion in this field which reduces spinning costs simultaneously on several levels. With the Recycling Xtreme equipment, spinning mills can save considerable raw material costs.

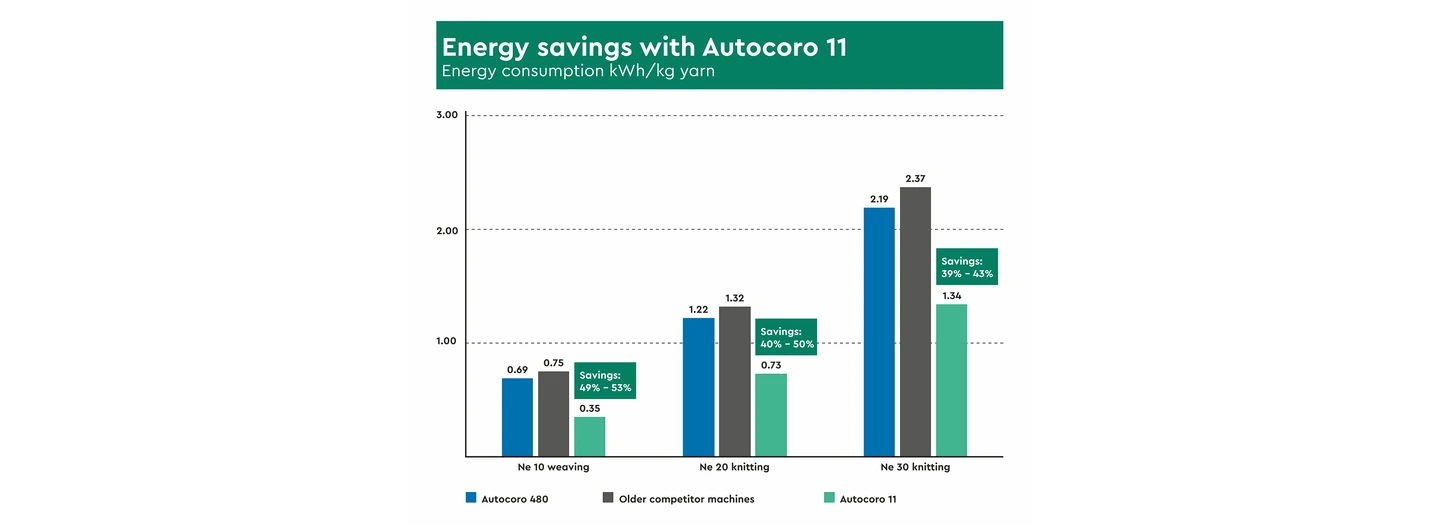

The advanced full automation reduces the need for personnel and, thanks to comprehensive energy optimisation, each Autocoro 11 uses 10% less energy than its predecessor, and up to 48% less in comparison with older rotor spinning machines.

The key energy-saving factor – the new extraction system of the Autocoro 11

Around 30% of the energy required for spinning is used to provide the negative pressure necessary for the process.

For the Autocoro 11, Saurer has designed, practically from scratch, an extraction system with everything needed for vacuum logistics. The result: A completely redesigned extraction system, modified ducts with a capacity increase of up to 85% that is resistant to pressure fluctuations. New air filter systems and a completely revised electronic control of the vacuum supply can now supply each of the different spinning processes individually with the suction air required.

For example, the pure spinning process is supplied with suction air just as precisely as the yarn search during the initial spinning phase. Gone are the days of compromises, when simultaneously operated processes were supplied from a single compressed air supply and were therefore not 100% energy-optimised. Energy-saving air technology is the top priority for the new Autocoro 11.

One of the powerful workhorses in the Autocoro is the winding device. It needs energy to move and wind tonnes of yarn reliably throughout the year. The Autocoro 11 winding device is equipped with state-of-the-art, energy-optimised drives, enabling Saurer to reduce the base load. The numerous electronic components of the rotor spinning machine, such as the power supply units, were also checked and optimised with respect to their energy efficiency.

Energy cost savings in the six-figure range with the Autocoro 11

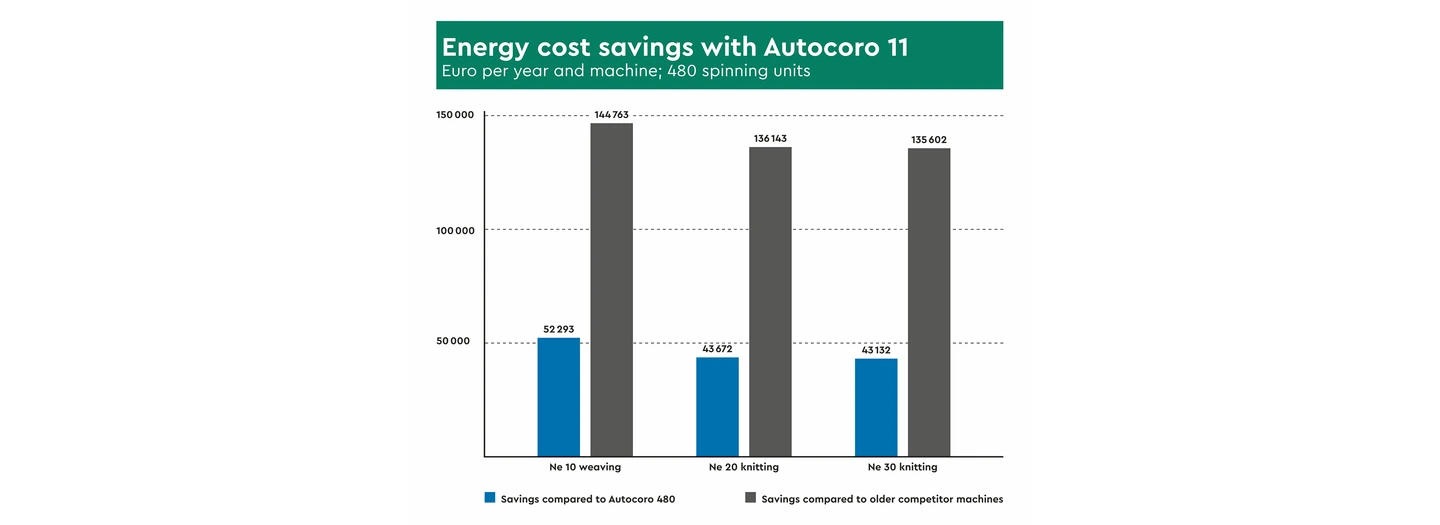

Compared to older generations of rotor spinning machines, many of which are still in use in various spinning mills today, the new Autocoro 11 saves up to 48% in energy costs. (Figure 1) Even with moderate energy prices of just €0.10/kWh and relatively short machines with 480 spinning positions, cost savings per year and machine are in the six-figure range (Figure 2).

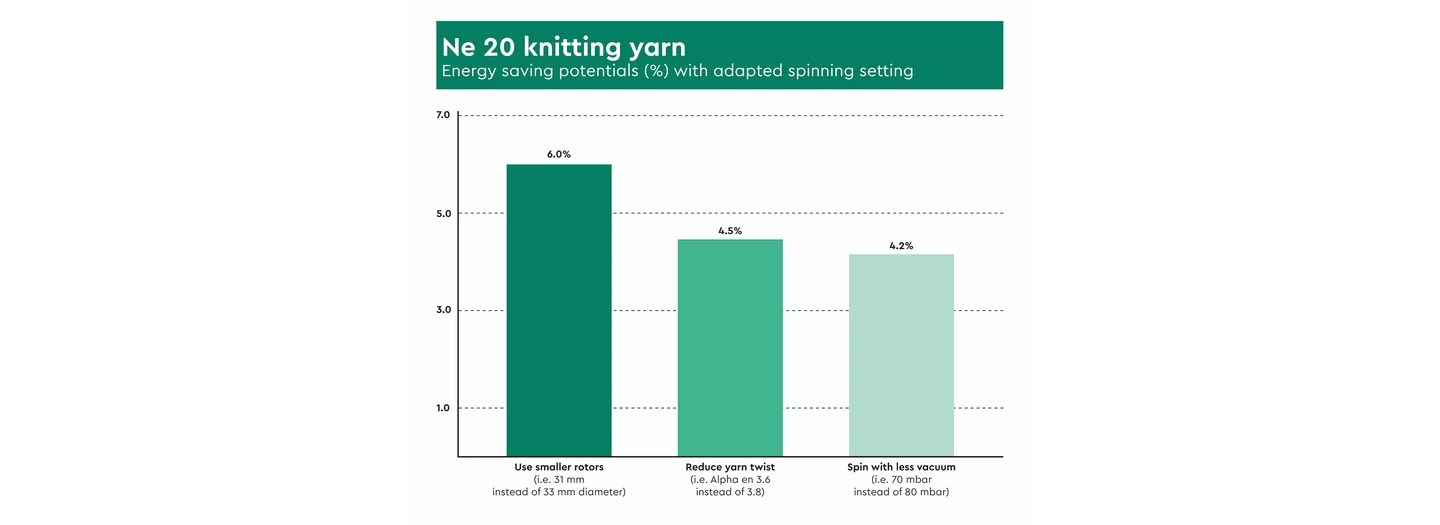

With Autocoro 11 customers can explore additional savings potential through a particularly energy-optimised spinning setting. These include measures such as reducing the spinning vacuum and the twist, increasing the rotor speed and using energy-saving small rotors (Figure 3).

Energy costs can be reduced by a further double-digit percentage by skilfully combining several measures, based on the respective raw material and the quality requirements of the yarn.

The cost savings achieved by using the Autocoro 11 are an important aspect. Reducing energy requirements also means contributing to sustainability, an aspect that is becoming increasingly important in terms of achieving global climate targets. There are already spinning mills that use solar panels on their roofs to generate all the electricity required by their Autocoro spinning mills in a climate-neutral way.