Antimicrobials Throughout History

Application of natural antimicrobial agents on textiles dates back to antiquity, when the ancient Egyptians used spices and herbs to preserve mummy wraps. Hundreds of years ago, the Chinese used bamboo — which contains an antimicrobial substance called bambookunin housing structures and design.

During World War II, both the Allied and the Axis powers used antimicrobials to prevent textiles from rotting. Tentage, tarpaulins, and truck covers needed to be protected from microbes born of heavy rain and snow that would eat through the fibers. Cotton duck, webbing, and other military fabrics were treated with mixes of chlorinated waxes, copper and antimony salts that stiffened the fabrics and gave them a distinct odor.

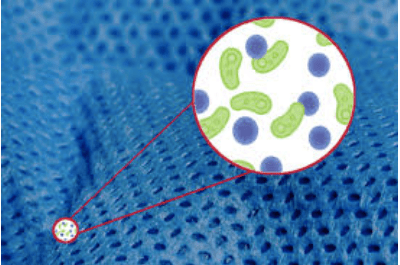

Antimicrobial is an agent that kills microorganisms or inhibits their growth. Antimicrobial fibers then are textiles to which antimicrobial agents have been applied, either at the surface or within the fibers. Additives can be introduced to the fiber during spinning or extrusion, combined with dyes or pigments or applied as a finishing process. The chosen method is determined by a variety of factors including final use of the fabric, the capability of the manufacturer and budget.

The Fight Against Microbes

The National Institutes of Health reports that microbes actually outnumber a human’s cells by 10 to 1. To be fair, not all microbes are bad, but inhibiting the unchecked growth of microbes in contemporary society can be of critical importance as these pathogens, bacteria, and fungi quickly multiply and can lead to adverse health effects.

A 2016 study by Morais and colleagues found that some bacteria populations can double every 20 to 30 minutes under ideal conditions, meaning that one single bacteria cell can increase to 1,048,576 cells in just seven hours.

Textiles’ large surface area and ability to retain moisture enable microorganism growth. This growth leads to a host of unpleasant effects for both the material and the end user. The growth of microorganisms reduces the textile’s mechanical strength, stains the fabric and lets other, more pernicious microbes breed. This is one of the reasons apparel is packaged in airtight bundles; one bad microbe in a moisture rich cargo container can ruin a whole shipment of textiles.

The effect on the end user’s health is even more important. Unchecked microbe growth leads to odors, infection, and the possibility of contamination. Since textile goods, particularly those made from natural fibers provide an excellent environment for microorganisms to grow, the need to protect and preserve them became fundamental. Therefore, these fibers are of key importance in sanitation and medical applications.

Antimicrobial protection range includes antimicrobial additives for textiles. These additives can be introduced into a textile during the manufacturing process to make it resistant to microbes. An additive will encompass a specific antimicrobial active, such as silver, and can be formulated to suit the material type, the manufacturing process employed and the desired end-use of your textile product.

Antimicrobial treatments can be easily and cost effectively applied to tetiles & fabrics at any stage of the production process, without affecting the inherent characteristics of the fibre. In addition to being added into the material itself, our antimicrobial additives can also be applied to any textile as a topical or finishing treatment.

Antimicrobial additives are suitable for addition to both synthetic and natural fibres including:

• Polypropylene (PE)

• Polyethylene terephthalate (PET)

• Nylon (PA)

• Wool

• Cotton

• Silk

What are the Benefits of Antimicrobial Textiles?

Wash after wash, antimicrobial textiles are proven to resist harmful bacteria by up to 99.9%. This inbuilt protection means fabrics benefiting from our antimicrobial treatments are less susceptible to staining, bad odours and degradation. Research has also shown that antimicrobial textiles maintain high levels of antibacterial performance for their expected lifetime, making them ideal for manufacturers of sportswear, hospital scrubs, non-wovens, bedding, technical fabrics, workwear and a range of other textile products.

Where Antimicrobial Products Are Used

Antibacterial textiles are used where moisture and microbes meet. The materials see use in a variety of applications including healthcare; hygiene; medical devices; sportswear; food packaging; storage; thermal and mechanical protection; automotive textiles; heating, ventilation and air conditioning; air filters; and water purification systems.

They are used to protect healthcare personnel with functional clothing as well as fabrics all around the home, including socks, mattresses, baby diapers and coverings.

Anywhere there are substances for the microorganism to feed on, antimicrobial fibers can be seen in some shape or fashion. For example, substances added to fibers, such as lubricants, antistatics, natural-based auxiliaries — including sizes, thickeners and hand modifiers — and dirt provide a food source for microorganisms. Antimicrobials of varying strength are used in order to prevent, inhibit, remove or kill microbes.

Reference:

1. Tomšič B, Simončič B, Orel B, Žerjav M, Schroers H, Simončič A, Samardžija Z (2009) Antimicrobial activity of AgCl embedded in a silica matrix on cotton fabric. Polymers 75:618–626Google Scholar

2. Turner SL, Bailey MJ, Lilley AK, Thomas CM (2002) Ecological and molecular maintenance strategies of mobile genetic elements. FEMS Microbiol Ecol 42:177–185

3. Walsh CT, Wright G (2005) Introduction: antibiotic resistance. Chem Rev 105:391–394

4. Wang ZL (2000) Characterizing the structure and properties of individual wire-like nanoentities. Adv Mater 12:1295–1298

5. Weitz JS, Hartman H, Levin SA (2005) Coevolutionary arms races between bacteria and bacteriophage. PNAS 102:9535–9540

6. Whitman WB, Coleman DC, Wiebe WJ (1998) Prokaryotes: the unseen majority. Proc Natl Acad Sci USA 95(12):6578–83

7. Yurieva O, Kholodii G, Minakhin L, Gorlenko Z, Kalyaeva E, Mindlin S, Nikiforov V (1997) Intercontinental spread of promiscuous mercury- resistance transposons in environmental bacteria. Mol Microbiol 24:321– 329