A new level of carpet yarn quality: The GVA, a machine for heat-setting carpet yarn, takes the heat-setting process to a new level – and celebrates its 50th birthday in 2021.

Born in 1971 in Töging am Inn, a small town near Munich in Germany, the GVA (GVA stands for “Garnveredelungsanlage” and means the refining of carpet yarn) was constructed by Resch Maschinenbau, when the company was commissioned to construct a single head machine for textile treatment to be presented at the ITMA in October 1975. However, the experience during the ITMA pointed towards a greater interest in a multiple head machine.

Therefore in 1975 Ludwig Resch sen. developed the first six-headed yarn heat-setting machine (GVA) for Hoerauf Suessen. In 1976 six machines had been sold and in 1977 already 14 machines.

Soon after, Resch Maschinenbau (Power-Heat-Set was founded as a sister company in 2002) received the first orders for the American market.

From 1978 to 1987 400 GVAs were shipped to the United States as well as 30 machines to various customers in Europe and Japan, later worldwide to Saudi Arabia, Turkey and China.

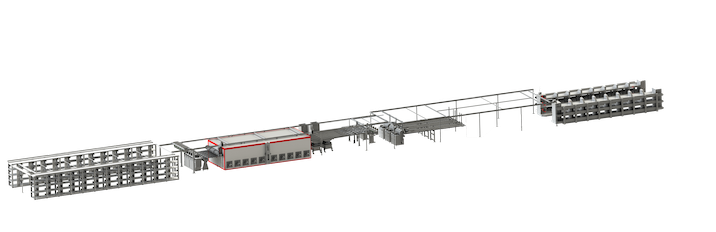

Throughout the years the GVA was developed and improved and in 1995, the first GVA 5000 with doubled capacity was manufactured. Nowadays, all textile activities are concentrated at Power-Heat-Set GmbH, which has its own testline for design, research and development.

The GVA now offers the best flexibility and high performance for heat-setting carpet yarn with up to 96 ends. Due to its six-channel configuration, the GVA is a perfect solution for running high volumes of uniform production efficiently, but it also provides the flexibility to run six individual lot sizes while offering the ability to process frieze or straight yarn on any position.

It utilizes superheated steam with the full capacity of heat-setting natural or synthetic fibers with an enormous output from eight to 17 tons of yarn per day.

Customers all over the world appreciate the high GVA standard with constant improvements, quick installation and worldwide service. Even today, there are several first generation GVAs that are still running after 20 years.

This is strong evidence of the high quality of Power-Heat-Set machines which are also aiming at sustainability in production. Low energy consumption and sustainable materials are an important element of the Power-Heat-Set philosophy and therefore, of course, for the new generation of GVA.

Especially the Middle East is one of the most important markets with new challenges of carpet-yarn-treatment procedures.

“As per our experience this area is full of innovation and high-quality products in the carpet and carpet yarn industry and therefore, we pay maximum attention to the needs and requests of our customers in the Middle East”, explains Marcus Köhler, CEO of Power-Heat-Set.

Innovation is the key to the GVA success story. Demands on techniques and technologies change almost every day as the markets are influenced by many aspects such as fashion and trends, purpose of yarn/carpet, materials, technology, raw material availability and production costs. These changes mean a permanent challenge to the creative developers and determine the GVA of tomorrow.

As in the past, Power-Heat-Set today continuously works on optimizations to meet every customer’s needs and the expectations of carpet yarn market – and to bring the GVA to the next level.