An interview of Mr Anuj Bhagwati, Head – A.T.E. Group

1. Please tell us about the history of the A.T.E. Group and its success story.

A.T.E. was founded in 1939 as an agency house representing a few German textile machinery manufacturers in India.

Today, we are still in the agency business, and some of our relationships are 70 years old! We represent 50+ global leaders in textile engineering across the textile value chain in India, and some in Bangladesh as well.

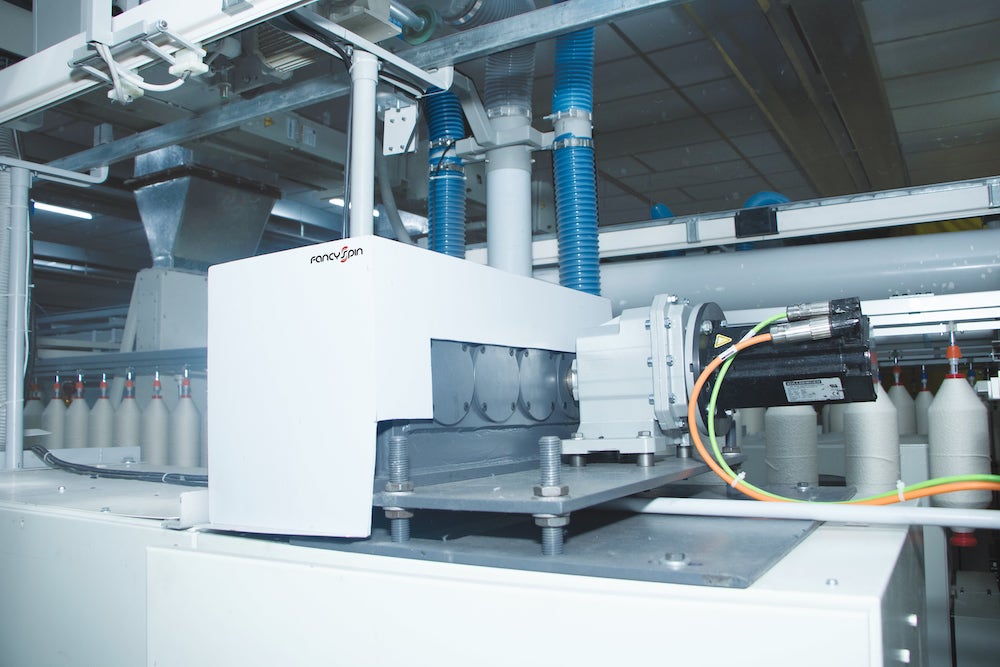

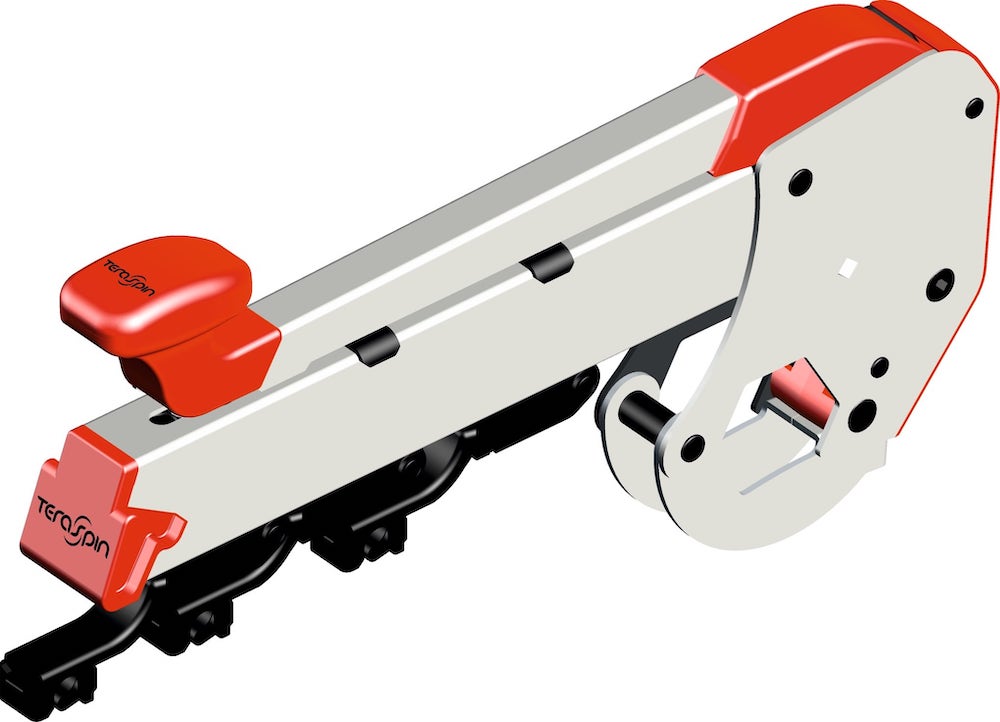

In the next chapter of our story after agency, we ventured into textile machinery and accessories manufacturing. In textile engineering, we have our own manufacturing for precision spinning machinery components under the brand TeraSpin, and two joint ventures: Truetzschler India, a j/v with Trützschler, Germany, to manufacture spinning preparatory machinery, and KARL MAYER Textile Machinery India, a j/v among KARL MAYER, Rabatex Industries and A.T.E., to manufacture warp preparation machines and creels.

At A.T.E., we have always taken our responsibility to the environment seriously in our own operations and this has become an integral part of our business strategy. We have built up businesses offering end-to-end wastewater treatment solutions; energy-efficient cooling and solar heating; value-added products for textile, packaging, etc., and industrial IoT. ‘Invent in India’ has been one of our major themes and we have developed several proprietary technologies. Our solutions find applications in a wide range of industries, apart from textiles – from the automotive and engineering industries to food and beverages, pharmaceuticals, etc.

I believe that our growth and development stem from our values-based management, our service mindset, our commitment to technology, and our strong relationship with our customers and principals spanning several decades.

2. Which kind of machineries and services do you offer to textile companies locally and in international scale?

Our portfolio for the Indian market covers:

▪ Textile machinery and utility solutions for spinning, knitting, weaving, non-woven, technical textiles, processing and printing

▪ Textile machinery accessories, retrofits

▪ Flow technology: pumps, mixers, aerators, and controllers

▪ After-sales-services that include installation and commissioning, troubleshooting, AMC, etc., for some of the machines.

We offer the following products and solutions for India and international markets:

▪ Precision spinning machinery components

▪ Upgrade and automation of legacy machines

▪ Wastewater treatment, recycling and sludge management solutions including ZLD

▪ Cooling: evaporative air cooling, treated fresh air systems, hybrid air-conditioning

▪ Concentrated solar thermal (CST) systems

▪ Industrial IoT solutions

▪ Viewing and inspection, electrostatic control, and heat recovery from exhaust air

Besides production and utility solutions, our portfolio also helps customers address some of their other critical challenges such as energy conservation, resource optimisation, and product quality improvements.

3. What is special about your high-speed spindles? What are the special specifications?

TeraSpin spindles are supplied with our well proven HF series of inserts. These spindles are produced for minimum friction; which is crucial for high speed spindles. Millions of spindles are running on various makes and models of ring frames across the globe with HF inserts. Our spindles are indeed well accepted by spinning mills around the world.

Our spindles are designed to run up to a maximum of 25,000 spindle speeds (mechanical), depending on the application, and have very low vibration and noise levels.

Our further innovations in spindles include:

▪ Spindles with Smart Yarn Catcher, which are self-cleaning and hence do not allow accumulation of residual yarn left behind after every doff, virtually eliminating the need for cleaning residual yarn.

▪ Premium ES (energy saving) spindles, which are available with 18 mm wharve dia. with HF-1/HF-100 inserts. These spindles are specifically designed to reduce energy consumption significantly.

We can supply the spindles for any make and model of ring frames. We are among the few manufacturers across the globe who manufacture in-house complete spindles and inserts for ring frames.

Our spindles work synergistically with our drafting systems as well. Our new ring frame drafting system, for example, is very easy to retrofit, and significantly upgrades ring frame performance. That’s a truly sustainable strategy – extending asset life by many years.

4. Let us know more about the A.T.E. Group’s latest machineries, innovations, and R&D achievements.

Climate change and the resultant rising global temperatures are major challenges faced by humanity. Unfortunately, one of the most common cooling technologies – air conditioning – is energy intensive and a contributor to global warming.

One of A.T.E.’s business units, HMX, has developed green cooling technologies that can be used for all cooling applications. We have developed the DAMA (dry air moist air) heat exchanger which is used in our indirect evaporative cooling (IEC) solutions. HMX’s cooling solutions provide energy efficient cooling and improve worker productivity and health by creating healthy work environments that are rich in fresh air. DAMA is a patented technology – we have been granted Indian, US, and Australian patents.

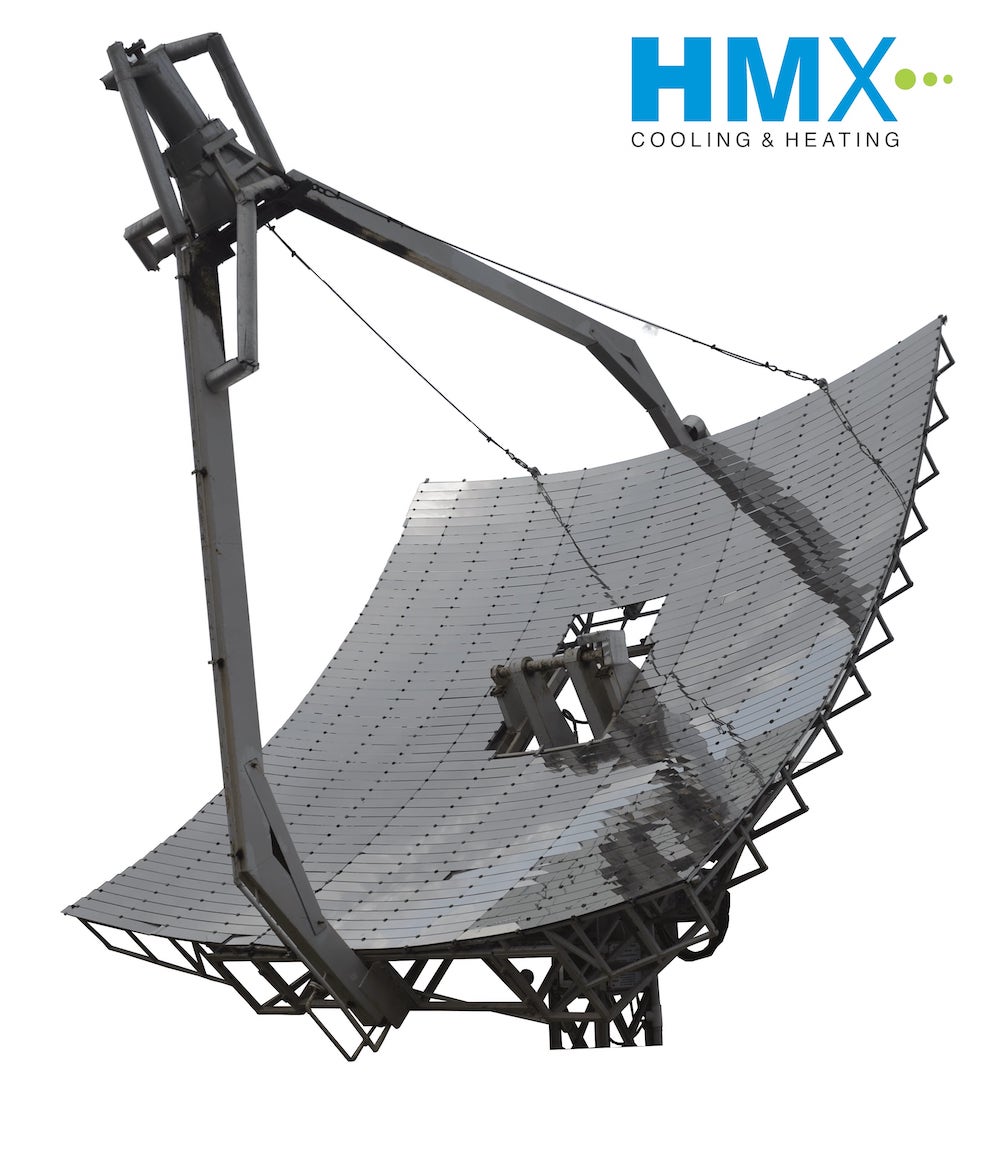

HMX also offers concentrated solar thermal solutions to generate low pressure steam or hot water that help reduce dependency on carbon-based fuels.

EcoAxis, another business unit of A.T.E., has developed SuperAxis™, an Industry 4.0, Internet of Things (IoT) enabled analytics application that can be used in plant or monitoring of utilities. Our industrial IoT solutions have helped many customers reduce waste by reducing rework and rejections, and energy consumption, while increasing capacity utilisation.

We have a range of static control and vision and defect detection systems, developed by AxisValence, an A.T.E. business unit. Amongst other applications, these systems also are useful for fabric defect detection. For example, DetectAXIS is an intelligent supervisor that helps reduce the wastage of costly raw materials and improve quality.

DetectAXIS ensures 100% defect detection – it can spot and flag defects as small as 0.01 mm2, thus helping manufacturers ensure consistent print quality. AxisValence’s antistatic solutions are used in the removal of unwanted static charges that hamper quality and productivity in various textile processes such as spinning, fabric forming, processing and non-woven manufacturing. We also have static charging solutions that are used in flocking and mask manufacturing.

5. Textile industry in one of the most polluted industries specially in terms of water. How can your wastewater management systems help to textile industry to be cleaner and environmentally friendly?

Textile processing is water-intensive. The water that is to be discharged after the process is full of dyes and chemicals. We thus face the twin challenges of first making freshwater available every day for production needs, but then also ensuring zero pollution. We believe the answer lies in changing our mindset and accepting the idea that the most secure source of water is actually wastewater. If we can do this, we solve both challenges in one go: convert waste to value by recycling precious, clean water from wastewater; generate biogas from wastewater and also recover energy and nutrient potential from biosludge. Less cost of water transport means further reduced carbon emissions.

Textile wastewater can be complex to treat due to variability in the pollutants in the water – such as dyes, organic and inorganic compounds, polymers, etc. This makes reducing the chemical oxygen demand of textile wastewater a challenge.

Our group company, A.T.E. HUBER Envirotech (AHET), is specialised in providing technologies for industrial and municipal wastewater treatment, recycle, and ZLD (zero liquid discharge) and sludge management systems. Our highly successful AAA® technology was developed specifically to handle complex textile wastewaters. With AAA®, chemical consumption and sludge generation can be reduced by nearly 70%, COD and colour by 85%, and power consumption by 25%. Additionally, AAA® also ensures a consistent quality of treated water with a reduced plant footprint!

AHET’s SUFRO technology is a simple and efficient alternative to conventional ultrafiltration and reverse osmosis (UF-RO). The SUFRO® system comprises of a submerged membrane filtration, a high quality, ultrafiltration membrane laminates with 38 nm pore size instead of the conventional pressurized UF system, followed by a reverse osmosis plant.

This technology provides huge benefits in terms of savings in chemicals of up to 50%, up to 50% lower backwash and CIP water requirements, and around 30% reduction in footprint. SUFRO eliminates many equipment from the conventional treatment scheme with UF-RO. It provides dual protection: protects upstream biological systems from upsets and also downstream RO plants from fouling by providing better quality of treated water than the conventional UF.

Apart from textiles, we also provide wastewater treatment solutions for industries such as sugar and distilleries, food and dairy, petrochemicals, paper and pulp, and more.

6. As a textile expert how do you evaluate the textile sector in India in recent years?

India has a strong domestic market for textiles of all sorts and is also a global sourcing hub for many products. The home textiles sector has grown explosively, as have a few others. Technical textiles are emerging as a sunrise sector, becoming more relevant during the COVID-19 pandemic. The usage of specialty fibres in a wide range of applications means that we will see an uptick in technical textiles – both domestically and globally. Given the exponential potential for technical textiles, this sector is expected to get a major fillip from the Indian government. All in all, I am confident that the Indian textile industry is quite resilient and would grow robustly not only in the short term but also the medium and long term.

7. How do you predict the Indian textile industry will perform after the coronavirus pandemic?

The Indian textile industry was badly hit in the initial phase of the pandemic due to multiple factors such as reduced demand, low liquidity, and labour migration, etc. At the same time, it was also presented with new opportunities; nonwovens is a particularly good example.

From an acute shortage of personal protective equipment during the initial stages of the pandemic, the Indian textile industry was able to scale up production substantially by the end of 2020.

The Indian textile industry was able to bounce back almost from the mid of 2020. As per Wazir’s report 2021, India’s domestic textile and apparel market is expected to grow by a CAGR of 10% by 2025-26 and export is expected to grow by a CAGR of 11% in the same period. We have seen that the investment by the textile industry in modernisation/expansion has picked up substantially since the contraction that took place in the beginning of the pandemic.

We also find a great deal of interest in automation and digitalisation. Textile manufacturers are realising that digitalisation and process automation are necessary to take them to the next level.

8. Sustainability and green products are a must for the future. How can we have a sustainable textile industry and what is role of textile machinery in this process?

Environmental sustainability essentially involves energy, water, and land. The textile industry needs to focus on all the three elements; to conserve energy, to reduce, recycle, and reuse water, and to reduce and recycle wastes to free up land space.

While the need for energy conservation and wastewater recycling are intensely discussed, I would like to focus on the last bit, i.e., freeing up land.

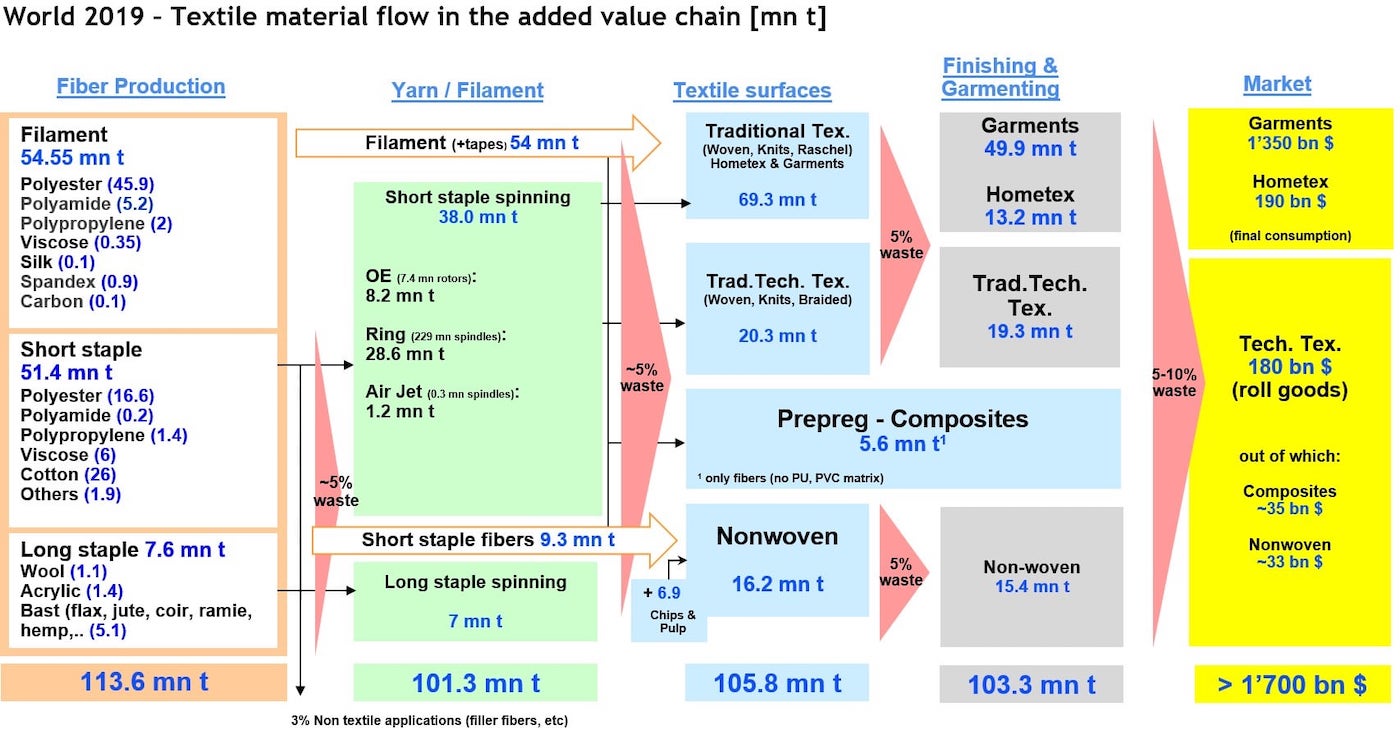

The global textile industry produces millions of tonnes of material every year as shown in the image from the well-known textile consultants, Gherzi.

Much of this material, at the end of its life cycle, inevitably ends up in landfills. In fact, textiles form a major part of landfills worldwide. Recycling this material will free up land, reduce water and energy use, and reduce contamination of ground water and surrounding soil. Textile recycling is an area that machinery manufacturers need to focus on much more.

Just as wastewater is recycled back into the textile process, textile manufacturers need to view textile waste as a source of raw material. This calls for a paradigm shift not only in the thinking of machinery and equipment manufacturers and textile manufacturers, but in legislation on a global scale.

Another important step that we can take to manage sustainably is that of digitalization. The vision is that we can get wisdom from data – and transform from a hindsight driven, to a foresight driven organization in the process.

The new technologies of the internet of things (IoT) and the speed with which these can manage and process data allow us to move first from descriptive analytics – a description of what happened; to diagnostic analysis – and answer the question of why it happened; then you can move to predictive analytics and think of what will happen; and finally, to prescriptive analytics and answer the question of what is the best thing to do.

With IoT there are many advantages for sustainability. For example, we can decrease the specific energy and water consumption; reduce carbon emissions; enhance indoor air quality’ and actually build sustainable savings. In some of the projects that we’ve done, we’ve seen savings of 1-5% on overall cost, savings of water and energy of around 15% and so 15% of carbon emissions as well. The payback on such investments is just a few months.