Diamond Fabrics, part of Pakistan’s premier vertically integrated Sapphire Group, has selected Belgian based BMSvision as a partner for its prestigious MES project, the keystone in the roadmap towards a I 4.0 company.

Mr. Tayyab Abdullah explains: ”We were looking for a solution that goes far beyond the traditional production and machine monitoring.

In order to prepare for an I 4.0 compliant manufacturing operation, we need a Manufacturing Execution System (MES) that can manage and track the entire production flow, from yarn to finished fabric.

Furthermore, the system needs to seamlessly integrate with the SAP ERP system in place. After thorough market research and various demo’s and workshops, we selected BMSvision as our partner because of their vast experience in the industry and the turnkey project approach including hardware, software and services”.

In a first phase of the project, the warp preparation department including ball warping, sizing and rebeaming as well as the complete denim finishing department are covered. These are the most challenging operations within a denim mill. In the second phase, all looms will be connected. Each machine in the preparation and finishing department is equipped with a state-of-the-art touchscreen-based DU11 data collection terminal with wireless barcode scanner.

Once the production orders are released by the SAP system, the planning department uses the BMSvision scheduling software (PlanBoard) to assign the orders to the individual machines. Orders are started at the machine by scanning the barcoded batch travel card. The PlantView application visualizes the complete production process in real-time and highlights any possible deviation from standard. A powerful reporting tool featuring interactive reports and charts, allows the users to create their own calculations and reports.

After each production step, the MES systems prints a barcoded ticket and all relevant production data is transferred to the SAP system. Diamond’s request to monitor and document the flow of goods throughout the whole production chain, to be able to trace all materials used and to know the current status Work in Process all the time, is handled by BMSvision’s traceability module.

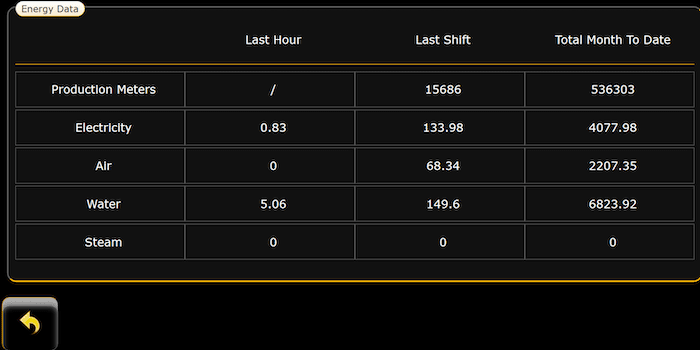

Besides managing the production flow, Diamond Denim also implements the BMSvision EnergyMaster solution. Mr. Tayyab Abdullah: “Energy consumption is becoming a very important factor in the overall operating cost of our factory. With ever rising energy prices and increasing environmental legislation, energy management has become a very critical success factor to run our business in a profitable way.

The EnergyMaster system makes all our energy streams transparent and allows to allocate the exact energy cost to each production batch”. The finishing lines are equipped with power meters and various flow meters to monitor consumption of compressed air, steam, water, gas and caustic.

All these meters are connected to the DU11 data collection terminal and combining consumption with production data allows correct calculation of the energy cost for each production batch. Excessive consumptions or consumptions while the machine is idle, are immediately detected and highlighted.

BMSvision is proud to be a partner of Diamond Fabrics in the continuous improvement program of their operations.

About Sapphire Textile Group

Sapphire Textile Group is one of the largest textile producers and exporters in Pakistan. The manufacturing from yarn to finished fabric is done in various plants using the most advanced machinery and equipment. Its customer base includes the industry’s biggest names in Asia, Europe and North America.

About BMSvision

BMSvision, established in 2007 as a carve-out from the Barco group, is a leading supplier of Manufacturing Execution Systems (MES) for discrete manufacturing, with focus on the textile and plastics industry.

Under the brand name BMSvision (formerly BarcoVision) and with over 40 years of experience as a former division of the Barco group, BMSvision offers a wide range of systems aimed at productivity, quality improvement and energy management.

BMSvision is present at key locations around the world, either with own branch offices or through a world wide network of agents and service centers. BMSvision is represented in Pakistan by ZONA Technologies.