An interview with Suzanne Abetz / Managing Director of Filtech Exhibitions Germany

By: Middle East Textile Journal

From February 23-25 the city Cologne in Germany becomes again the top meeting point for the worldwide filtration and separation community. Trends and innovations for textile filter media as one main topic at FILTECH 2021

Please let us know more about FILTECH 2019 Statistics and success story.

Last FILTECH 2019 could welcome 428 exhibitors, about 500 delegates at the congress and in total 16500 visitors from 75 nations, who experienced and discussed the latest filtration and separation products, developments, trends and innovations, from which filter media are an important topic.

FILTECH is the most prestige event in the filtration industry, please let us know more about how FILTECH is important for this sector?

In a unique way, FILTECH 2021 presents all relevant techniques and apparatuses for wet and dry particle separation. In addition, adjacent topics are covered, which are of significant importance for filtration and filter media, like adhesives, applications of ultrasonic and plasma technology, cutting systems, pleating or other special machines. Last but not least methods and equipment to analyze the materials to be separated, to control the quality of apparatus components and to realize remote control of separation processes are included.

The general trend towards intensified digitalization can be recognized under several aspects at FILTECH 2021 again. “Digital Twins” are presented, which have been developed not only for training purposes but also for predictive control and optimization of separation apparatuses and machines. The “intelligent” machine registers with sensitive sensor techniques the operating conditions and maintains the stationary operation despite arising disturbances.

As an example, Andritz has developed an RFID-tracking chip, which is integrated in the filter cloth of filter presses and provides data about its status. This makes it possible to react in time on disturbances or to register fatigue effects.

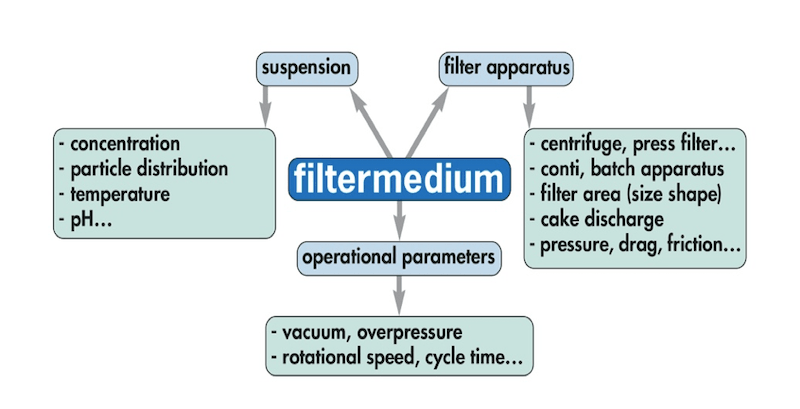

Generally spoken filter media are the decisive centrepiece of all filtration processes and the interface between particles in liquid or gas, apparatus and operation conditions. Only, if these three aspects are well adjusted to each other, a filtration process will work properly. The figure below explains for wet filtration these correlations between suspension, filter apparatus and operational parameters of the filtration process.

This is the reason for the huge variety of completely different filter media, which are consisting of different materials, exhibit different pore structures and are produced by different methods. Woven wire fabrics, non-woven fleeces and felts, wedge wire sieves, porous sinter materials, various types of microporous membranes, packed beds consisting of particles and others are examples for this variability.

FILTECH 2021 reflects the latest state of the art for filter media development and especially for textile filter media under most different aspects, like application, production, additive functionality, testing and analysis, numerical simulation of flow properties and others.

For woven wire filter fabrics, a trend towards smaller pore diameters, larger throughput and enhanced stability can be observed. The concept of the Swiss company SEFAR to increase particle retention and simultaneously flow rate of their polymeric monofilament fabrics is based on a special double weave technology. Such a fabric consists of a thin upper layer of fine pores and a coarse pored mechanically stable sublayer, like well-known from asymmetric membranes for nano- and ultra-filtration.

This is in principle not new, but formerly such media were manufactured by connecting two separate fabrics with deficiencies like crimping or intrusion of particles between the two layers of fabric. Now both weave layers are produced on the same loom as one piece and are interconnected.

Another strategy is realized by the company Haver & Boecker, which has developed an innovative three-dimensional weaving technology. The arising weave structure increases the open sieve area significantly for the same filter area and thus nearly doubles the flow rate in comparison to conventional structures. The new fabric can exhibit small pores down to 5µm with comparatively thick wires. This is not only cheaper but special materials like Avesta, Hastelloy, Inconel or Titanium now can be used to produce extremely fine-pored filter media.

A similar lace weave has been developed by GKD-Kufferath. For 5µm pore size, an increase of the flow rate of 25% in comparison to conventional fabrics of larger pore size could be achieved.

The development of optimized structures not only of woven wire fabrics for the surface filtration but also of nonwoven felts and fleeces from micro and nanofibers for depth filtration more and more are supported or even based on most modern numerical simulation techniques. Several presentations on the FILTECH 2021 conference are dealing with the latest results from this field.

Most modern production methods for highly efficient filter media, like advanced pleating systems or laser drilling machines for micro-pores <1µm will be presented as well as latest developments to analyze pore sizes for quality control in filter media production processes.

Additional functionality of filter media shows a further actual trend of research and development. Electrically charged nanofibers for improved separation, plasma coating to control the wettability of filter media, special adsorptive properties of textiles or integration of hydrophilic microporous membranes in woven wire fabrics can be mentioned here.

It is expected, that the latter could be able to realize a spectacular new way of vacuum or pressure cake filtration without gas throughput and thus minimizing energy consumption.

These days everybody worries about COVID, what is your plan for FILTECH 2021 in terms of visitors and exhibitors health concerns?

FILTECH 2021 exhibitors deliver solutions for current and future challenges. One is the COVID situation. Many FILTECH exhibitors offer a variety of solutions for protective equipment.

Innovative HEPA Filter do play an important role because they reduce aerosols and particles loaded with viruses. Mobile filtration units will help to guarantee safety. Also, indoor air quality monitoring instruments featuring highly precise fine dust measurement, and even virus monitoring are currently developed to guarantee perfect air quality and a minimized infection risk.

At FILTECH 2021 these innovations will not only be on display but also in action to guarantee a safe business atmosphere for visitors and exhibitors alike. FILTECH as a very focused show does not struggle with the problems huge mass event have. Classical measurements like distancing and hygiene rules are easy to follow and are complemented with the latest technology.

As a successful exhibition organizer, what do you think about Virtual exhibitions? Is it an impermanent solution or it is a preparation for future world?

Virtual/hybrid shows do in most cases, not more than offering companies a website to present their products in a broader way than they do normally. At FILTECH we follow this concept for many years now.

FILTECH exhibitors can upload all information, brochures, films, pictures/graphics in 10 languages free of charge and make the information available all year long at the FILTECH website. That way the FILTECH website became a very important information platform for visitors and people who are unable to attend our show alike. But are we a virtual/hybrid show? No.

What do you think about MENA region filtration and nonwoven Market and its future?

The MENA region has a long textile history and can revert to a profound textile knowledge. That’s why this region became so important for textile production especially in the apparel and home textile sector. Producing technical textiles for the growing filtration industry offers MENA manufacturers the possibility to enter into a new market with lots of potentials.

Book Your Space Now …

Contact Person: Suzanne Abetz

P: +49 2132 93 57 60

[email protected]

www.filtech.de

Filtech Exhibitions Germany

PO Box 1225

40637 Meerbusch – Germany