UPSCALE YOUR PERFORMANCE; 100% COLOR MONITORING LEADS THE WAY!

Profitability is taken to the next level with the best technology on the market. Resource conservation and utilization are – and remain – two of the most important aspects in all manufacturing processes. So, spinners rely on YarnMaster® PRISMA to take them another step towards maximum profitability.

Once again, Loepfe delivers pioneering technology to the textile market. As proven in the latest customer trial, the detection of foreign matter in all colors opens up new possibilities in terms of quality, profitability, optimal use of raw materials and process optimization.

Maximum performance with 100% color monitoring

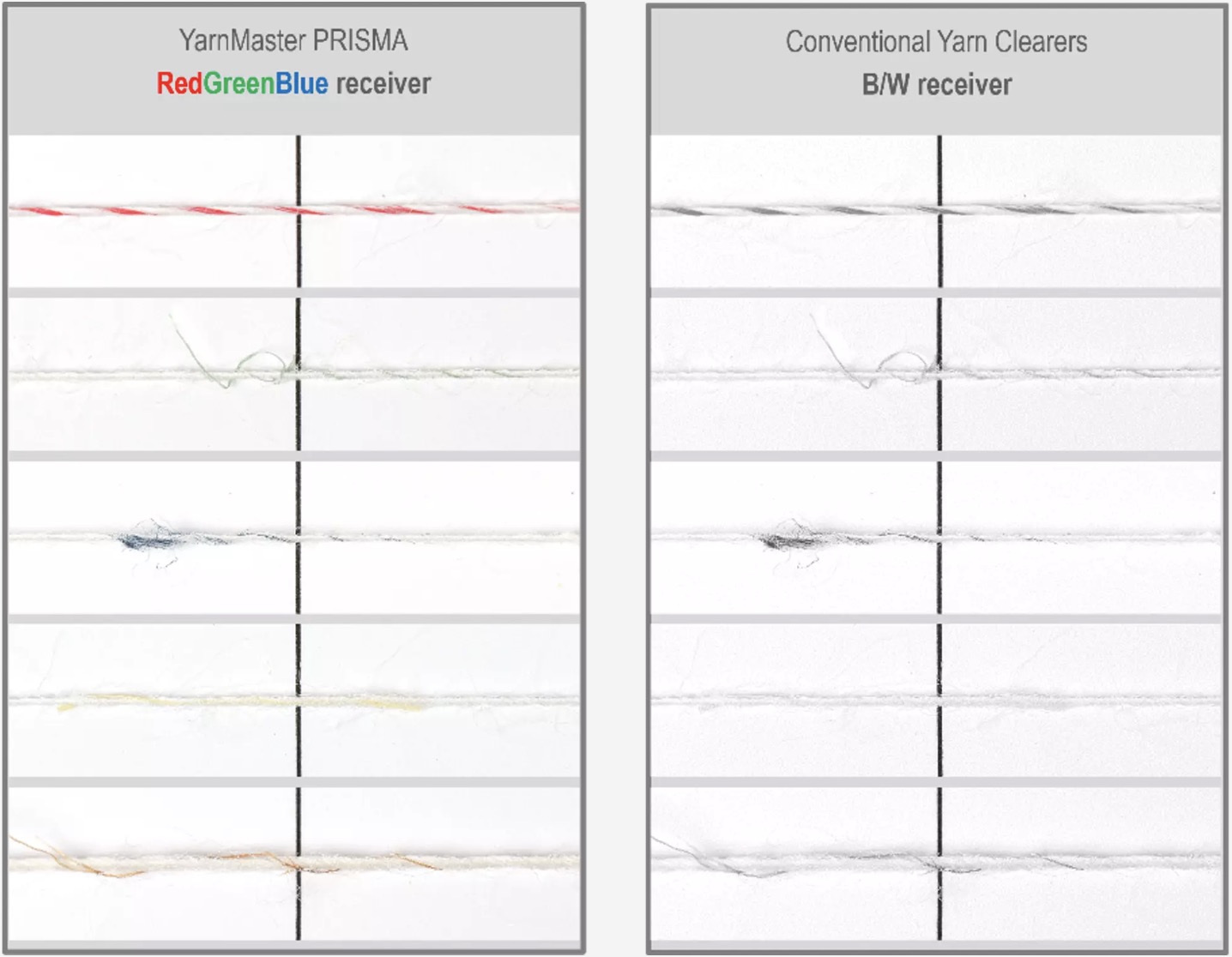

Seeing is believing. The control and handling of contamination in cotton are some of the biggest challenges in spinning technology. With the introduction of YarnMaster PRISMA, Loepfe has set a new benchmark in quality control, especially for cotton, but also for colored yarns, melange yarns and man-made fibers.

Loepfe’s newly developed F-sensor enables 100% color management for the first time in the history of yarn clearing. True foreign matter detection eliminates unjustified cuts which directly leads to higher performance and a reduction in yarn waste.

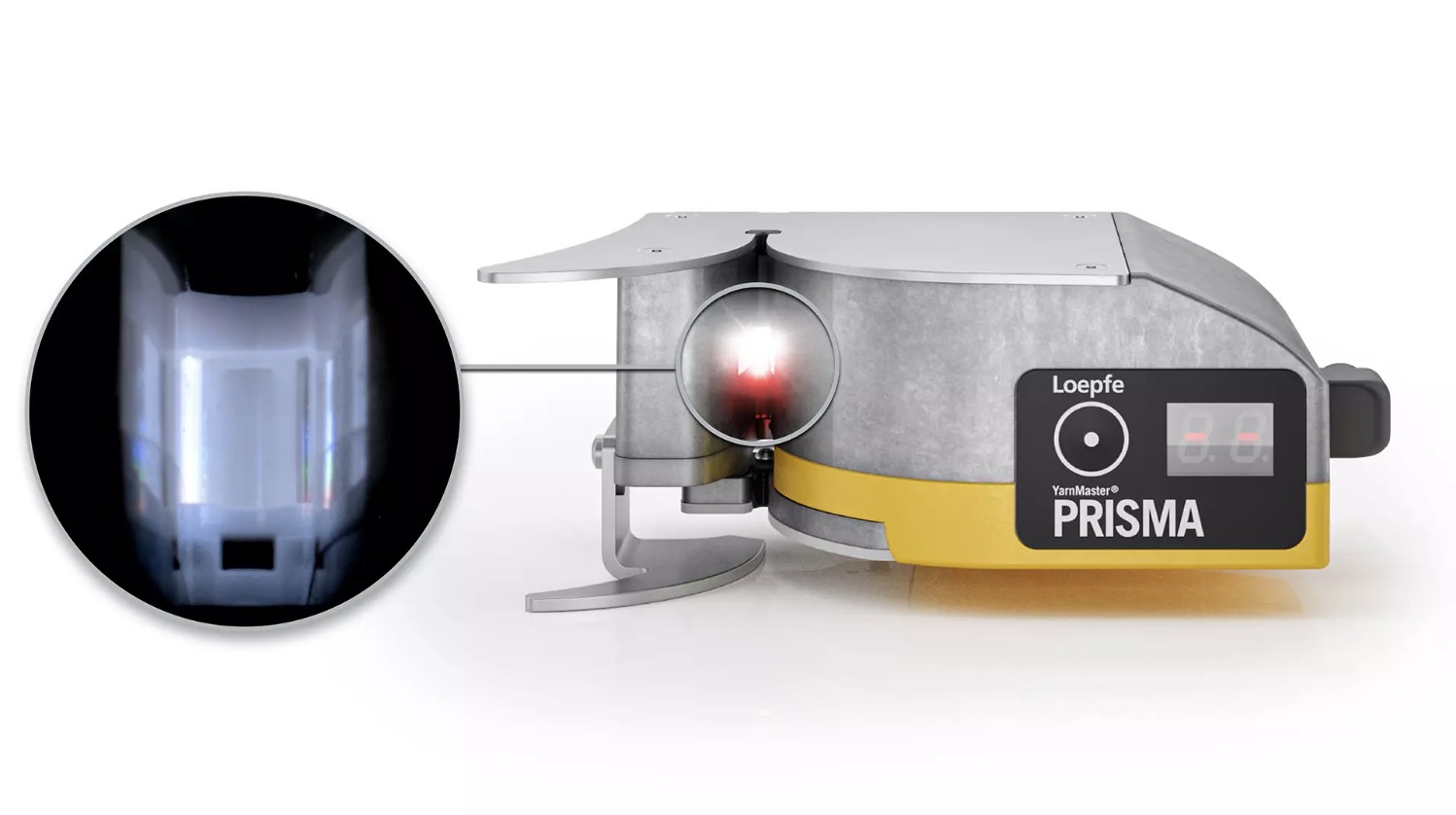

The RGB technology used by Loepfe to detect foreign matter and organic components of cotton, is based on detection with the full spectrum of light. The yarn gets illuminated in the full spectrum of light using the additive RGB color model.

This unique technology for yarn quality control uses the three primary colors – red, green and blue – adding wavelength to enable full-color monitoring, a globally unique feature. RGB technology makes it possible for the first time to precisely detect all colors, thus scan the whole raw material and classify the unwanted components within it.

Optimized reflection and adapted optical technology in PRISMA further results in 360° all-round monitoring. This novel clearing technology achieves unprecedented precision in the yarn clearing of staple fibers.

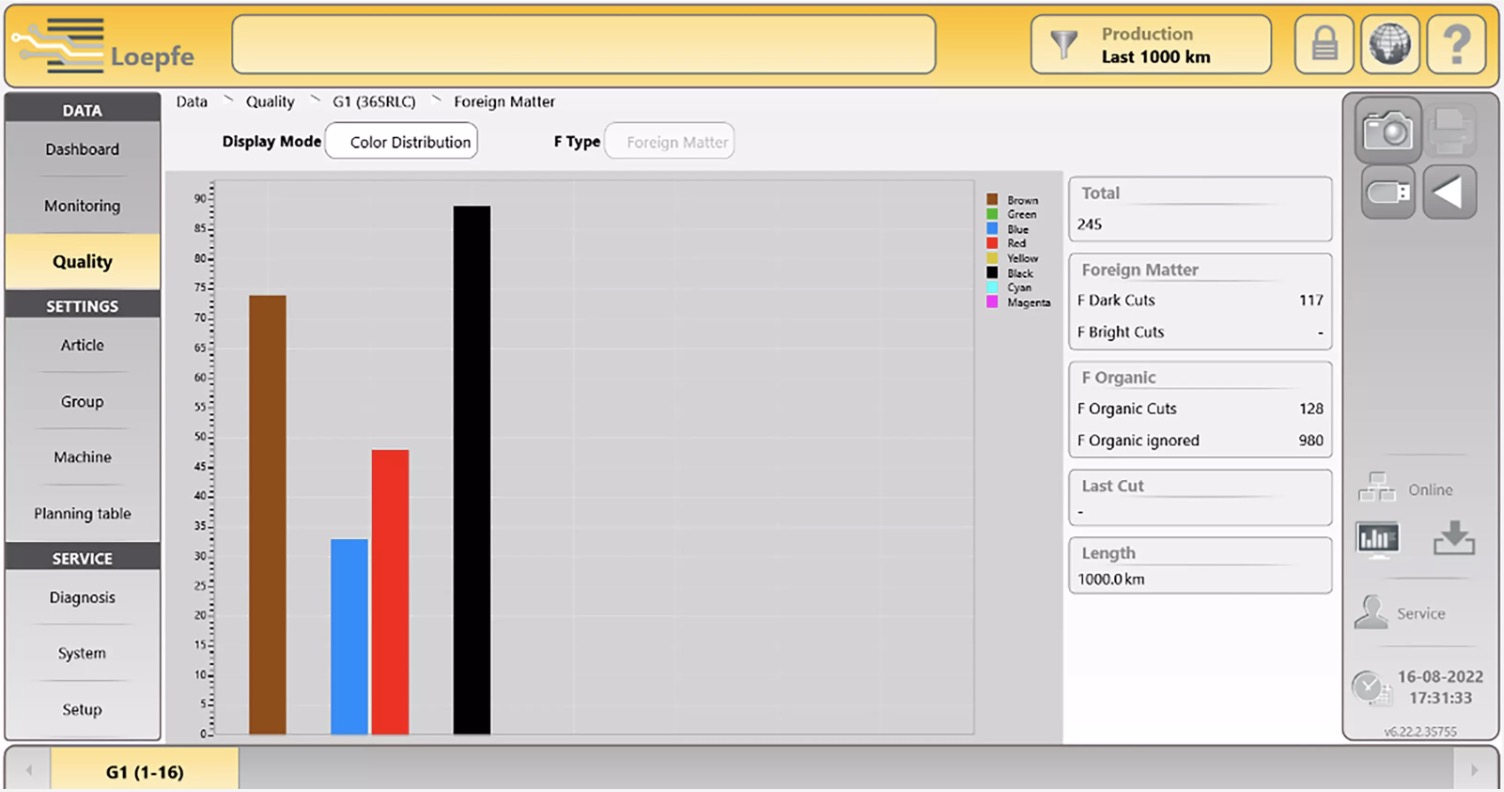

Production optimization through a Cut History overview

The PRISMA operating system provides a Cut History in which the detected colors are displayed for each cut. This enables data-based decisions on quality–mill management optimization and helps to increase efficiency from the blow room to the winding machine. This unique feature provides important information about 100% of the spun yarn and opens up new possibilities in raw material selection, blending, and cleaning.

Only the necessary: Intelligent organic filtering

PRISMA’s uniqueness supports increases in efficiency with a holistic approach. The PRISMA software system uses algorithms and statistical models to analyze and draw inferences from data patterns, ensuring recognition of all possible organic matter.

In addition to color management, RGB technology enables color-oriented selection of organic material in the cotton yarn, which does not necessarily have to be removed, as it does not cause disturbances in downstream process steps and is eliminated by other means.

Loepfe has fed the system with thousands of samples of organics, showing what they look like and how disturbing they are. The system can then recognize the organics without following explicit instructions, relying instead on the collection of organics and the patterns it has made from it. Customers can benefit from this intelligent organic filtering which offers an even more accurate detection of organic substances. The filter has learned whether organics need to be removed or not, leading to considerable savings, clearer cuts and higher winding efficiency. Machine learning methods take the organic clearing function to the next level.

Trials with several customers have shown that PRISMA is able to maintain yarn quality while increasing clearing efficiency through a lower cut-rate. This is achieved by the unique combination of software and precise and sensitive sensor technology which allows error-free detection and classification of disturbing or non-disturbing defects.

Focus on customer needs: Customer trial results

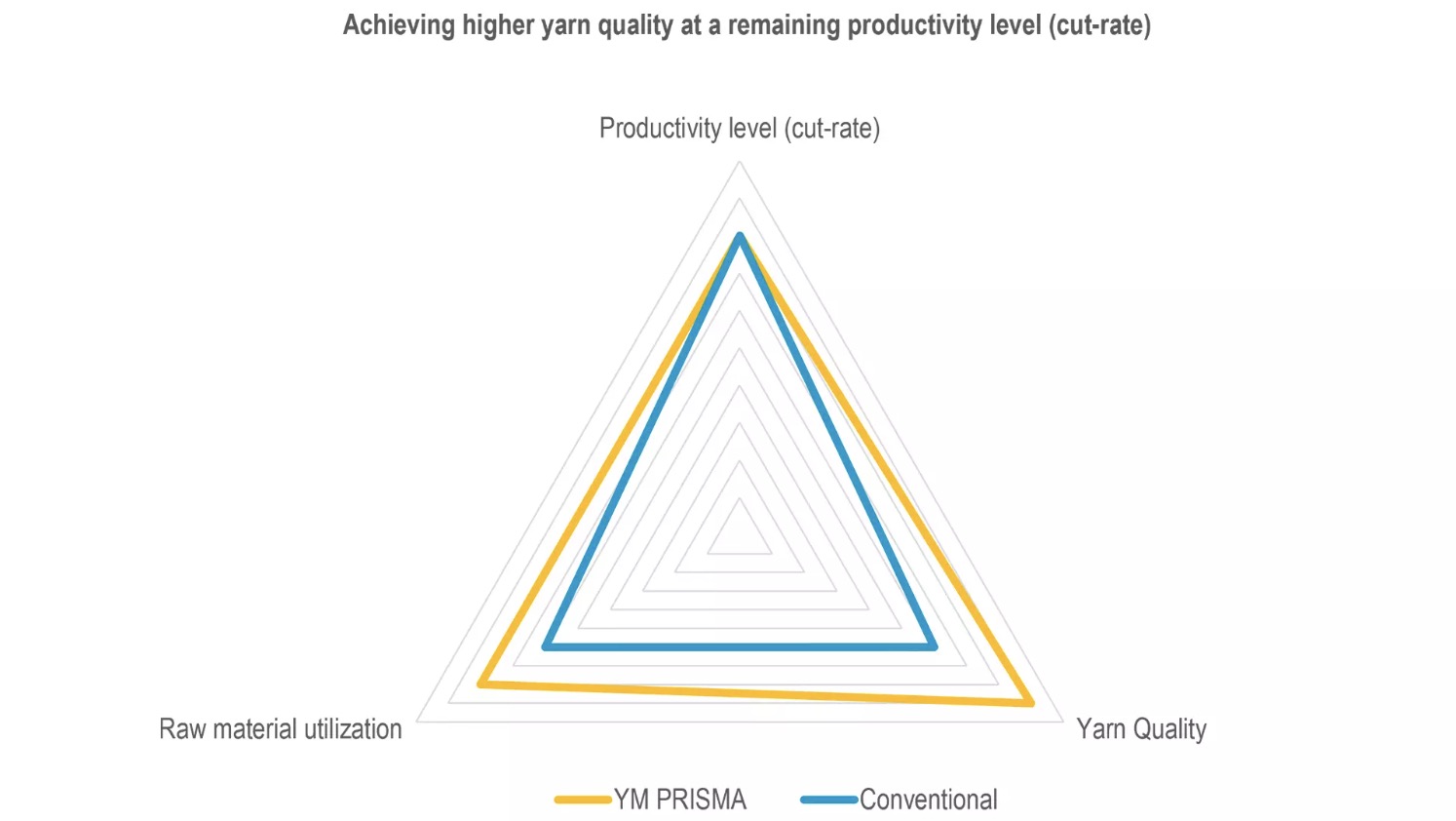

In production, certain parameters are given. The level of efficiency to be profitable and the level of yarn quality to guarantee flawless further production. Various customer tests have shown that the unique measuring technologies of PRISMA enable the producers to achieve a higher yarn quality at a fixed cut-rate, i.e. a fixed productivity level, or vice versa provides higher productivity (lower cut-rate) at a given yarn quality.

The graphic shows a test carried out with a customer in China manufacturing an Ne 60 compact yarn. Since the yarn quality now produced is not always satisfying, the goal was to reach a higher yarn quality while keeping the defined level of productivity (cut-rate).

The on-site test showed that the target – higher quality while maintaining the cut-rate – was met. This important production optimization was achieved by the more precise removal of colored foreign matter and fewer cuts on non-disturbing organic events. This result also achieves improvements in raw material utilization, since a higher quality could be achieved from the same raw material with the same cut rate. The performance of PRISMA convinced the customer and leaves him room for further optimization of his profitability. This new and trend-setting innovation shows once again how further optimization of spinning mills can be achieved through 100% online quality control with the latest technology on the market.