ERCA SPA, Patagonia® and YKK announce the successful implementation of ERCA’s REVECOL®, a sustainable, innovative chemical agent, in YKK’s dyeing processes at their Vietnam production sites.

ERCA transforms common waste material, such as exhausted vegetable cooking oil, into an upcycled, certified high performance, safe textile chemical ERCA has invested in circular practices to take waste material and use them as feedstocks to create new responsible chemical products.

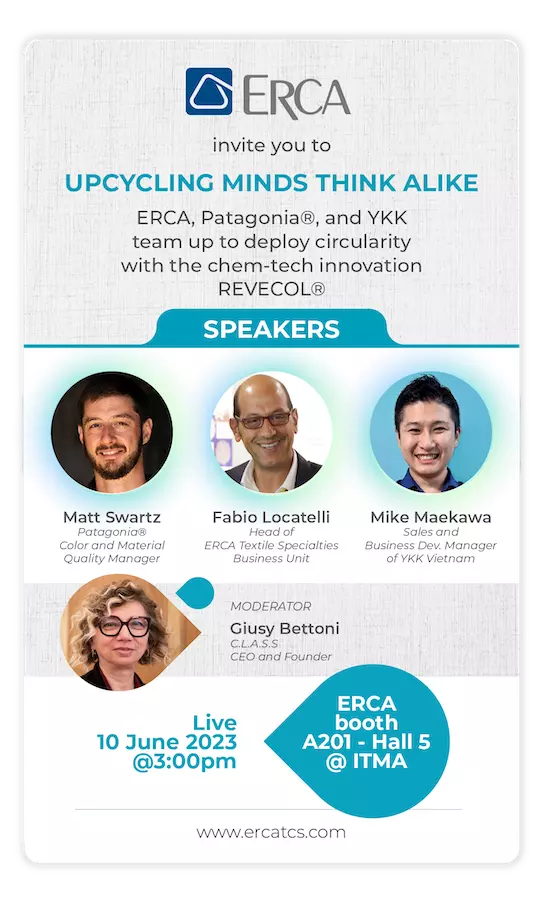

Always searching for new sustainable innovations, REVECOL® caught the attention of Patagonia®. Driven by the goal to utilize non-extractive chemistry in their supply chain wherever possible, the brand teamed up with ERCA and trim supplier YKK to deploy REVECOL®. Matt Swartz, Patagonia®’s Color and Material Quality Manager, introduced the ERCA technology to YKK, asking that they explore using it in their dyeing operations.

Always searching for new sustainable innovations, REVECOL® caught the attention of Patagonia®. Driven by the goal to utilize non-extractive chemistry in their supply chain wherever possible, the brand teamed up with ERCA and trim supplier YKK to deploy REVECOL®. Matt Swartz, Patagonia®’s Color and Material Quality Manager, introduced the ERCA technology to YKK, asking that they explore using it in their dyeing operations.

“We saw an opportunity to build a partnership with an innovator, ERCA, who was pushing the boundaries of sustainability and match them with an existing partner, YKK, that consistently delivers high caliber, quality goods and services. This has proven to be a dream team,” says Matt Swartz of Patagonia®.

“Through thoughtful consideration, we designed our approach and conversion to REVECOL® LV-TS to have an outsized impact from the start. The real success is seeing this go beyond Patagonia® products and spread across supply chain partners, brands and consumers. This is one domino to fall in how we do business to save our home planet.”

REVECOL® LV-TS has a carbon footprint that is 72% lower* than the more conventional chemical auxiliaries produced by ERCA. Today ERCA produces a wide range of high-performance chemical auxiliaries made from used vegetable oil that are ZDHC, bluesign® approved and GRS certified.

REVECOL® LV-TS has a carbon footprint that is 72% lower* than the more conventional chemical auxiliaries produced by ERCA. Today ERCA produces a wide range of high-performance chemical auxiliaries made from used vegetable oil that are ZDHC, bluesign® approved and GRS certified.

ERCA is the first company in the world to have GRS certified chemical products, opening the door to circular chemical auxiliaries.

“One of the most rewarding achievements is not only to see that REVECOL® can really make a difference, but that leading companies are teaming up with us to utilize it in products that bring the message of sustainability to the end consumer”, says Fabio Locatelli, Head of ERCA Textile Specialties Business Unit.

As part of their Sustainability Vision 2050, YKK is constantly working to deploy more sustainable chemical processes in their production. The ability to replace a commonly used dye chemical with a lower impact version was a no-brainer for YKK’s Vietnam management. REVECOL® is not only more sustainable, it is also more efficient, reducing the use of the dyeing auxiliary by 20% to 30%, thus helping to lower YKK’s overall chemical usage.

As part of their Sustainability Vision 2050, YKK is constantly working to deploy more sustainable chemical processes in their production. The ability to replace a commonly used dye chemical with a lower impact version was a no-brainer for YKK’s Vietnam management. REVECOL® is not only more sustainable, it is also more efficient, reducing the use of the dyeing auxiliary by 20% to 30%, thus helping to lower YKK’s overall chemical usage.

“We are thrilled to be part of this unique 3-way collaboration, exemplifying how true upcycling on a mass-production scale is made possible at the center of garment manufacturing. We look forward to the expansion of REVECOL® across the entire textile industry”, says Mike Maekawa, Sales and Business Development Manager of YKK Vietnam.