Man-made fibers are on the rise. Blends with different fiber materials are particularly popular. When processing man-made fibers and blends, short-staple spinning mills face different challenges than with natural fibers.

The most important challenges are the fiber finish, imperfect material in the form of fiber packages, the electrostatic charge, and the risk of heat-induced damage.

Rieter machines offer unique solutions for processing man-made fibers and blends from the blowroom to end-spinning and have been used in this field already for many years.

EXPECTED VOLUME IN 2030

38 million tons

Man-made fibers

29 million tons

SPECIAL SOLUTIONS FOR MAN-MADE FIBERS

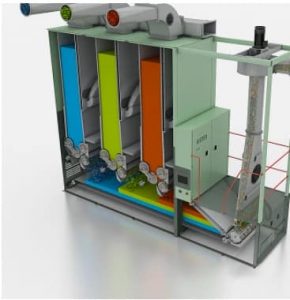

Blowroom

Man-made fibers need no cleaning, but they require especially careful opening. The Rieter opening line therefore offers different modules and clothings to adapt to different raw materials. The precision blender A 81 is the well suited for the constant mixing of different raw materials. For small lots and limited space, the mixing bale opener B 34 and the UNImix B 72 are ideal.

Solutions for man-made fibers

- Gentle opening of man-made fibers with S-modules and bypass option for high flexibility

- Special clothings for man-made fibers

- Perfect blending ratios with the precision blender UNIblend A 81

- The mixing bale opener B 34 is ideal for small lots

- For thorough mixing of the metered fibers, the UNImix B 72 and B 76 are the right choice

The UNIMIX B 72 for optimal blending in the smallest space Special clothings in the rieter opening line Perfect blending ratios with the UNIBLEND A81

Card C 80

The card C 80 with its maximum-sized technological carding area sets new benchmarks in high productivity and sliver quality for man-made fiber applications. With the longest pre- and post-carding zone, the opening intensity can be optimally adjusted. The largest active carding area with its 40 working flats and 1.5m working width contributes to maximum performance.

Solutions for man-made fibers

- Optimally adjustable opening intensity with the longest pre- and post-carding zone

- Easy cleaning thanks to the removable web bridge

- Special high performance clothings by Graf

- High delivery speeds with the web guided delivery unit

- Many technology parts made in stainless steel

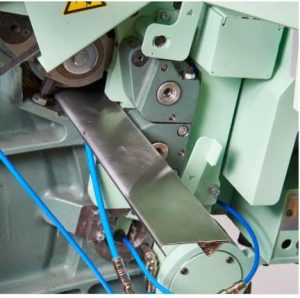

Draw frames (R)SB-D 50 and (R)SB-D 26

The sliver-run up to the coiler of the draw frames (R)SB-D 50 and (R)SB-D 26 has been designed for high delivery speed – also with the processing of man-made fibers and blends. The perfect sliver guidance is particularly important with bulky material.

Solutions for man-made fibers

- Trouble-free processing of bulky fibers with the power creel with bigger guiding funnels

- Long cleaning cycle and high yarn quality with polyester thanks to the coiler CLEANcoil-PES with special coating

- High speed and quality with big top rollers with cleaning lips

- Best yarn quality thanks to a variety of roller cots

- Longer roller lifetime due to quick pressure release to prevent hard laps

Roving frame F 40/F 20

The unique technology of the roving frame F 40/F 20 ideally prepares the roving for the ring spinning machine also when processing man-made fibers. With the optional electronic drafting system drive the main draft and break draft can be set on the machine’s touchscreen in no time to suit the characteristics of man-made fibers. Constant monitoring of the roving and bobbin build-up ensures the highest roving quality for all raw materials.

Solutions for man-made fibers

- Constant quality over the entire bobbin thanks to the monitoring of bobbin build-up with sensors

- Reliable tearing procedure during the doffing process to cope with the high tenacity of man-made fibers

- Stepless adjustment of the sliver in-feed speed to avoid false draft

- Optimal adaption to the properties of the raw material with the electronic drafting system drive

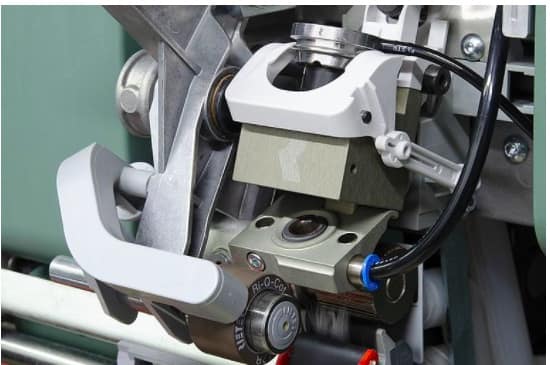

Ring spinning machine G 38

Synthetic fibers and their blends with cotton are commonly processed on ring spinning machines. Different blends with cellulosic fibers are another popular application. In general, ring spinning is very flexible compared to other spinning processes and reacts less sensitively to fiber finish deposits which is a common challenge when processing man-made fibers.

Solutions for man-made fibers

- Better guidance of the fibers with a stepped nose bar in combination with active cradle without pin

- Reliable cutting during doffing even for yarns with high tenacity thanks to SERVOgrip with knife

- High yarn quality with special rings and travellers for man-made fibers

- Increased lifetime thanks to reinforced front edges for separators

- Less fiber lapping with long and fine fibers thanks to the bottom roller with a diameter of 30 mm

- Optimal adaption to the cut lengths of man-made fibers by adjusting the width of the drafting zone

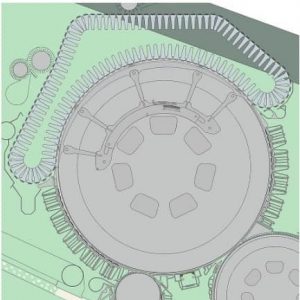

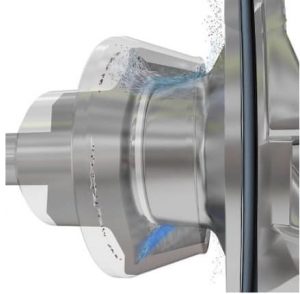

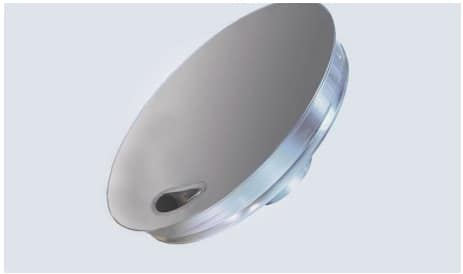

Rotor spinning machine R 70

Rotor spinning has its undisputed advantages when spinning short fibers, e.g., cotton with a high short-fiber content or recycled fibers. Due to the rotor technology, blends of longer and shorter fibers can be handled more easily than with other spinning technologies. Polyester fibers can typically serve as supporting fibers in combination with recycled cotton. When processing large quantities of short fibers, better yarn quality can be achieved due to the longer staple of polyester fibers. Thanks to the high evenness of rotor yarn, 100% polyester is also processed, mainly for technical applications.

Solutions for man-made fibers

- Exchangeable element CHANNELpass to adapt opening for cotton, polyester, or viscose

- Excellent spinning stability with the redesigned BYpass which features highly efficient extraction of impurities

- Potential for higher speeds thanks to Cool Nozzle Technology which avoids thermic fiber damage

- Better fiber flow and extraction of dust with SPEEDpass

- Intensive cleaning of rotor groove before each piecing process and when needed at doffing by the robot

Air-jet spinning machine J 26

Air-jet spinning is the dominant choice for processing cellulosic fibers – mainly viscose – and their blends with cotton. The J 26 offers several unique features for this. The machine is also well suited for processing blends with polyester: cotton with a proportion of up to 50% polyester and viscose with a proportion of up to 80% polyester.

Solutions for man-made fibers

- High yarn tenacity and production speed with viscose thanks to the new spinning nozzle housing Z+1 HS

- Stable fiber flow with the reshaped fiber feeding element

- Easy cleaning thanks to the option of opening the spinning nozzle housing

- Process security with all fibers and blends with the Q 10 A or Q 20 AF yarn clearer

- Uniform package quality and efficient downstream performance with pneumatic package damping