The cooperation with Balkan Textile Machinery. INC.CO completes our product portfolio for recycling by cutting and pulling solutions, making us the first full-liner in spinning preparation for recycling!

Thanks to our combined machinery expertise and technological know-how our customers can produce yarns at the highest possible quality level – and literally turn waste into value.

Together we can make a significant contribution to dealing with textile waste globally.

Osman Balkan Owner of Balkan Textile Machinery. INC.CO

Closing the loop – first full-liner in spinning preparation for recycling

We are happy to introduce Balkan Textile Machinery. INC.CO, a partner that not only complements our product line but also shares our values. Both Balkan and Trützschler are family-owned companies for whom sustainability in textile chain is a major concern. Balkan is well established in Turkey, one of the most important markets for textile recycling. Their robust and reliable machines help to cut, mix and tear textile waste to individual fibers, and to press them into bales of secondary fibers. These bales can be fed to the preparation process with Trützschler machines.

“We are now able to provide a complete line-up of technologi- cally leading machinery which has been specifically developed for rotor and ring yarns from recycled materials”, says Markus Wurster, Director Sales and Marketing at Trützschler Group. “Customers benefit from less complexity when planning and executing a mill project. The combined processes from Trützschler and Balkan are perfectly fine-tuned, reliable and reproducible. And of course, customers have access to Trützschler’s premium service.”

Osman Balkan, owner of Balkan Textile Machinery. INC.CO, adds: “I am very happy that we can join forces with such a strong international player like Trützschler. Together we can make a significant contribution to dealing with textile waste globally.”

Processing secondary fibers with appropriate card clothing

Of course, appropriate card clothing is part of our complete recy- cling solution. Trützschler Card Clothing continuously developed their card clothing to meet the technological challenges in the processing of secondary fibers and to improve the resulting yarn quality. Special attention has been paid to the flat top as the heart of the carding process.

Trützschler Card Clothing has combined the strength of MT/PT 40 and the cleaning power of MT/PT 45, resulting in the development of the MT/PT 45R – the new flat top for recycled materials. The right combination of flat top and cylinder wire is the key for yarn quality. Therefore, Trützschler Card Clothing offers various cylinder wires suitable for different recycling applications depending on production rates, type of textile waste and raw material – pure or blends. Thanks to this specification, customers can benefit from the best possible carding result, long lifetime of wires and high produc- tion in recycling applications.

“We are excited to offer our customers globally a complete package for recycling from June 2023 onwards”, says Markus Wurster, “including tearing line, blow room, card, draw frame, card clothing and of course our service and technological know-how.”

TRUECYCLED stands for state-of-the art recycling installations from Trützschler. These Trützschler preparation processes enable manufacturers to achieve a high-quality end-product from textile hard waste. With TRUECYCLED, manufacturers can rest assured they use the best technology and a reliable and reproducible manufacturing process – the pre-requisite for high quality yarn made from hard textile waste.

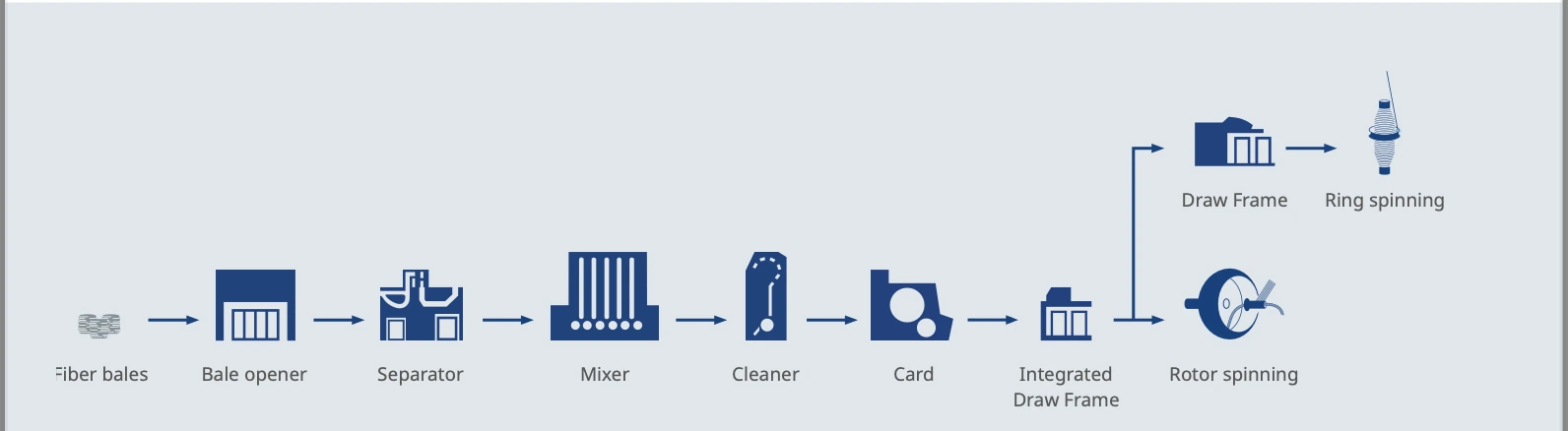

How does a TRUECYCLED process look like? It is based on Trützschler’s technological recommendations and a Trützschler machinery line-up to ensure best possible quality of the end- product: Be it a ring or rotor yarn or a wipe. For example, Trützschler recently worked with a fashion company to make use of their own pre-consumer waste.

Thanks to a special combination of Trützschler blow room machinery, the usage of TC 191 for Recycling and Trützschler draw frames, it was possible to create a ring yarn containing 60 % of pre-consumer waste- a true TRUECYCLED product! Trützschler customers and partners may use the brand TRUECYCLED for both the process itself and the end-product, as long as it contains a significant amount of textile waste.