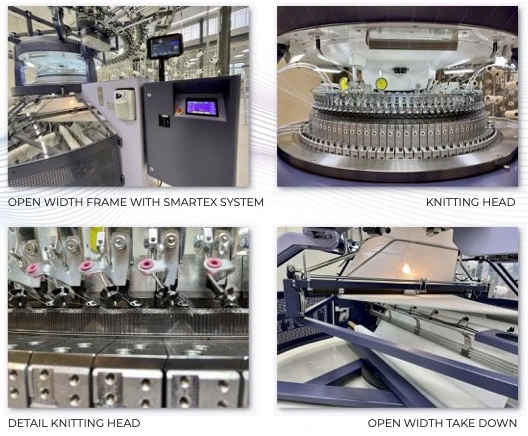

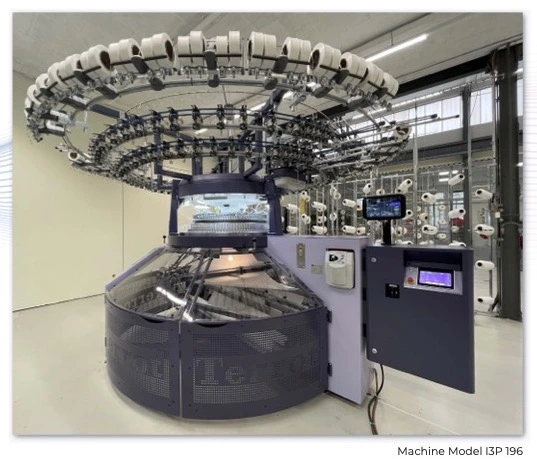

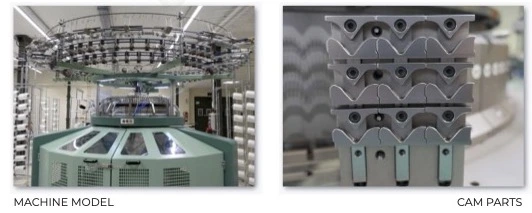

EXHIBITION MACHINE MODEL I3P 196 OPEN WIDTH FRAME PREMIERING WITH SMARTEX SYSTEM At ITMA

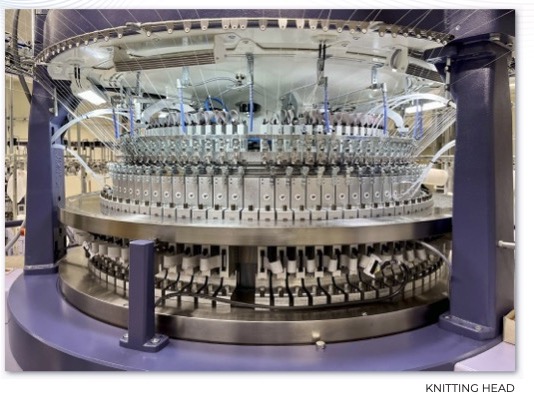

we will exhibit a highly flexible and productive I3P 196 „8-lock“, interlock and fine rib machine with open width frame that has been much demanded globally in the past years and after being tested by reputable clients of ours is much likely to become also a success story in your market.

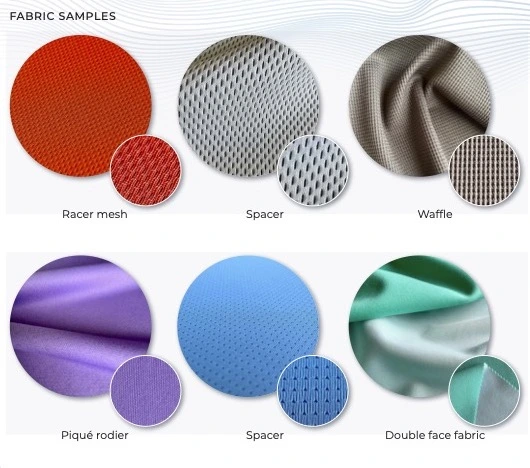

The I3P 196 is a highly productive knitting machine and creates „8-lock“, interlock and modified structures like punto di roma, milano rib, piqué rodier and also racer mesh with maximum efficiency. Equipped with up to 4 needle tracks in cylinder cam and 2 needle tracks in dial cam the I3P 196 promises maximum flexibility and a wide range of pattern options.

ADVANTAGES AT A GLANCE

• Highly productive knitting machine with a maximum speed factor of 1,050

• Terrot’s latest answer to market needs: most productive machine for „8-lock“ structures

(3.2 feeds per inch)

• Large gauge spectrum (up to E50) and timing delay up to 4 mm

• High-quality elastane plating in all variations

• Flexible application with spacer (height up to 4.5 mm) and fine gauge conversion kits

• Quick and easy gauge change

UCC 672-ME

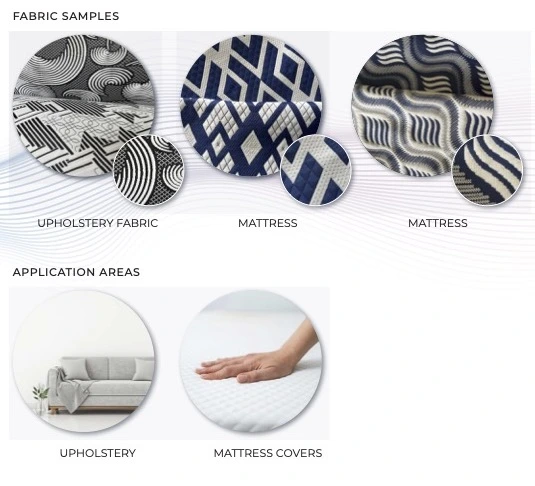

The UCC 672-ME in 3-way technology in dial and cylinder is Terrot’s flagship in the production of the highest quality mattress covers, upholstery and fashion with unlimited pattern possibilities on both fabric sides. With 88 feeders at 38“ (available from 34“ to 42“), newly developed dial needle selection and reliable elastane plating, the model’s flexibility and extremely high productivity are the newest demonstration of Terrot’s reputation as world’s leading producer of most sophisticated electronic jacquard machines.

MACHINE HIGHLIGHTS

• Most productive double electronic mattress and upholstery model worldwide

• Sharp definition of fabric structures on both sides with unlimited design options

• Divided dial cam system

• Flexible application with spacer, cast-off and shoe-upper conversion kits

• Reliable elastane plating

• New developed 3-way needle selection in dial

ADVANTAGES AT A GLANCE

• 2.4 feeds per inch and a maximum machine speed up to 19 rpm at 38“ guarantee high production outputs

• Fabrics in top quality with double electronic technology for a sharp definition of pattern structures on both fabric sides

• Divided dial cam system reduces set up times through quick and easy needle change without a complete removal of the needle selection units

• High-quality lay-in yarn carriers with integrated guidance for long floating threads

• Great flexibility and large pattern range with accurate needle selection in the cylinder and

dial cam for unlimited pattern options on both fabric sides

• Unlimited pattern possibilities due to 3-way technology on both needles – dial and

cylinder

• Fast pattern change without changing between knit and tuck cams

• Pattern/design software “Paint Terrot” for the quick and easy realization of different fabric

styles and pattern designs

I 1120

The Interlock model I 1120 as one of Terrot’s newly designed circular knitting machines with 34” and 136 feeders (30“ – 42“ on request) can be with many innovative and current demand reflecting features an attractive alternative to our blockbuster evergreen the I 2108.

You can reach maximum efficiency and productivity with an industrial frame and fabric rolls up to 1,050 mm. The motorized fabric take-down with three rollers and the automatic winding-up device supports industrial production at its best.

MACHINE HIGHLIGHTS

• Most productive double electronic mattress and upholstery model worldwide

• 4.0 feeds per inch and delayed timing up to 4 mm

• Gauge range from E18 – E42

• Speed factor 1150 SF (30” = 38 RPM)

• High-level elastane plating quality with special dial delayed timing cams

• Modified Interlock structures with tuck and dial synchronized knit cams

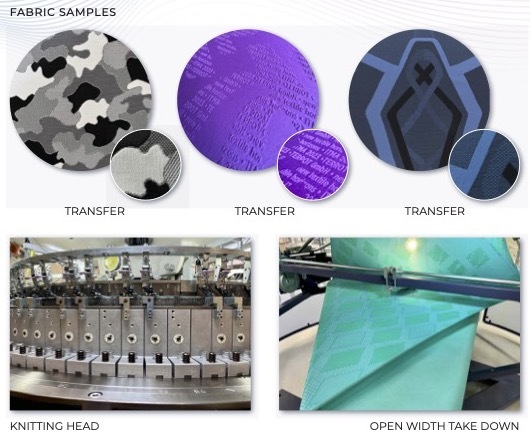

UCC 572-T

The UCC 572-T is Terrot’s flagship in the production of functional sport and leisure textiles, offering great flexibility and a high production output. The machine features a wide variety of applications while producing single and double jersey structure area combinations in ad- dition to hole patterns. This model makes designer’s dreams come true.

MACHINE HIGHLIGHTS

• High production of fine gauge transfer fabrics up to E24

• Highly productive (2.4 feeds per inch) in the cylinder and dial

• Available in different gauge settings in cylinder (E14 or E16) and dial cam (E28 or E32)1 for more application possibilities

• Combines single and double jersey structure areas to boost features like breathability, stretch and fit

• Creates sportswear with an improved fit called „Body Mapping“

• Reliable 3-way cylinder needle selection technology for knit, tuck and miss

• Reliable and high-quality elastane plating

• Unlimited pattern options with Terrot’s pattern design software “Paint Terrot”

JV-3.0 HIGH SPEED

Terrot extends its product portfolio even further and launches the new JV-3.0, which stands for high production outputs in the field of single jersey fabrics. This very productive knitting machine is easily capable of a speed factor of 1,280. In addition, other single structures like piqué can also be knitted with the JV-3.0. Despite its high efficienc,y the machine displays outstanding flexibility, long maintenance cycles and unseen operational convenience.

MACHINE HIGHLIGHTS

• Highest production of single knit fabrics with 3 feeders per inch

• Maximum output at highest quality

• Less wear and tear caused by newly designed sinker shapes

• Easy handling and reliable elastane plating

• Well known click-clack system (easy knit-on system)

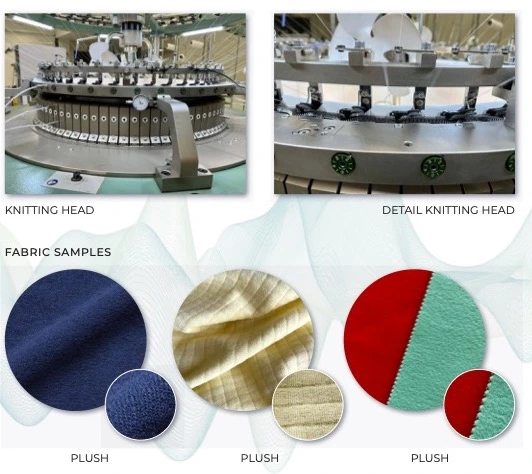

JSP5-4

The JSP5-4 produces high-quality plush with uniform loop lengths and provides a variety of different applications for various market requirements like fashion, home and technical textiles. Terrot offers different highly productive single jersey knitting machines for nearly every application and is very successful on the global market with its product portfolio.

MACHINE HIGHLIGHTS

• Lower shearing losses on fabric finishing

• Different sinker heights to realize different plush heights

• Great flexibility and large pattern range with up to 3 needle tracks in cylinder cam

• Different plating options (regular- and reverse-plating (known as polar fleece)) for a wide

application spectrum

• High-tech touch panel for an easy and user-friendly operation

• Depending on production requirements different frame types are available