END-OF-LIFE SOLUTIONS

Headquartered in Prague, Czech Republic, PFNonwovens has been a leading global producer and innovator of customized spunmelt nonwoven fabrics for decades.

This INDA member manufactures nonwovens for use in the personal hygiene market such as baby diapers, adult incontinence and feminine hygiene products and wipes. PFN also supplies construction, agricultural and medical applications.

Our tradition of innovation is continuing today with the development of a sustainable solutions platform to improve end-of-non-woven product life.

Tonny de Beer, Chief Technology & Sustainability Officer, PFN

PFN’s product advances include carbon footprint optimization and carbon footprint modeling. One example of these advances is our end-of-non-woven product life breakthrough innovation based on Smart Plastic’s SPTek ECLIPSE™ bio-assimilation technology, which renders polyolefin based nonwovens degradable.

Smart Plastic Technologies confirms that ECLIPSE™ is backed by the world’s first C-13 carbon labeling bio-assimilation test, which definitively demonstrated the transfer of carbon from an ECLIPSE™-enabled polyolefin film into the cell walls of microorganisms, creating biomass.

This joint venture in collaboration with Smart Plastic Technologies is progressing rapidly. Nonwoven manufacturing process validation steps including masterbatch addition and formula optimization have been successfully demonstrated.

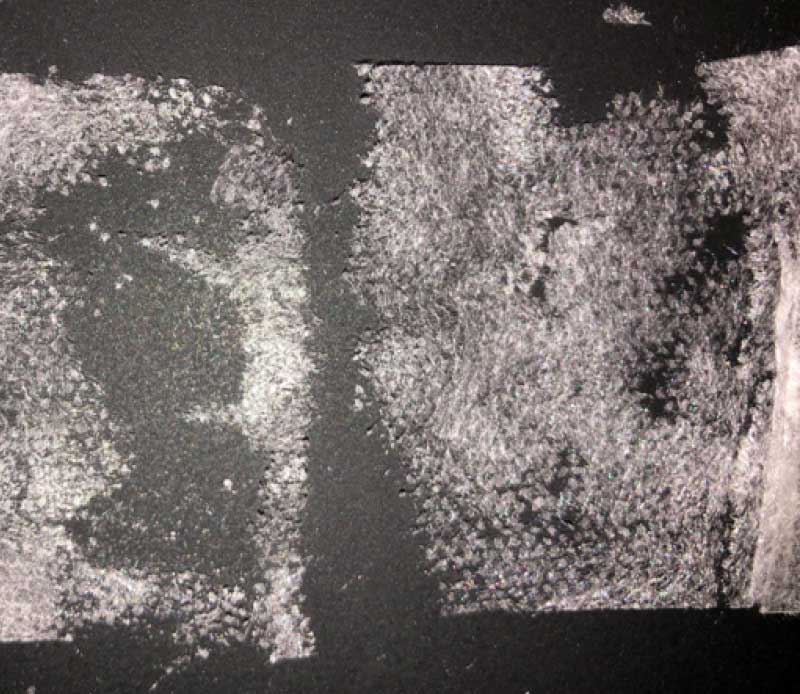

Accelerated aging tests of the ECLIPSE™-enabled nonwovens showed the desired rapid disintegration (e.g., polymer molecular weight reduction) profiles of the PP based material. Followup bio-assimilation tests, including microbial consumption resulting in water, small amounts of carbon dioxide, and biomass as final products at specific conditions simulating various end-of-product life environments (e.g. terrestrial, marine, etc.), are currently underway.

Finally, PFN’s robust corporate environmental sustainability program, which is centered around emissions and waste reduction, contributes to further reduce PFN’s impact on the environment. For example, 100% green electricity is now used at all the company’s manufacturing sites in the Czech Republic..