In 2018, the OPTIMA packaging group GmbH from Schwäbisch Hall (Germany) boosted its sales by around 15 percent to more than EUR 400 million, marking a new sales record for the company. Optima generated more than 85 percent of its sales abroad. The company employs more than 2,400 people across the globe – a number that’s increased by more than 100 over the past year. In 2019, the company is continuing to invest in new buildings at its headquarters in Schwäbisch Hall. An ongoing investment program spanning several years has set aside around EUR 50 million for construction projects. Optima plans to exploit the potential of digitalization even further in the future with an “Industrial IT” division created specifically for this purpose.

In 2018, Optima boosted its sales to more than EUR 400 million. “We’re also forecasting a positive trend for 2019 and beyond,” says Hans Bühler, Managing Director of OPTIMA packaging group GmbH. Bühler identifies the following growth drivers for the packaging industry – the growing number of single-person households calls for new, small packaging, the aging population is set to ensure growth in the pharma sector, and the number of consumers in developing countries with a high-income is on the rise. Bühler adds that “Optima also boasts a broadly diversified portfolio for all manner of industries, operates on the international stage and can therefore react quickly to new market requirements.” That’s why he feels it’s important to constantly adapt to changes and find solutions to new packaging trends.

Extensive construction projects at the headquarters in Schwäbisch Hall

A new building with office and assembly areas is currently being built for Optima Pharma at the Solpark industrial park in Schwäbisch Hall. The new building, which was originally planned to be built in three to five years, is realized earlier, on account of Optima Pharma’s extremely high level of incoming orders. Employees in the Materials Management Division moved into the new premises as planned in early July 2018. OPTIMA materials management GmbH plans to go live with the production operation of the automatic warehouse, which can accommodate more than 50,000 parts, in early 2019.

Growing workforce

The number of employees has skyrocketed – in 2017, there were already more than 2,250 people working for the special purpose machine manufacturer, but this figure had shot up to 2,400 by the end of 2018. The majority of the company’s staff are employed at its headquarters in Schwäbisch Hall, with the number of people working there rising to more than 1,700 in 2018. In Germany, over 2,000 members of staff contribute to Optima’s success. With the integration of the Bavarian company Maier Packaging in June 2018, more than 40 experts added an extra boost to the Optima Group. Maier Packaging focuses on converting and optimizing existing thermoforming and filling machines, constructing individual models for form-fill-seal machines (known as FFS in the business), creating banding and labeling systems as well as punch and mold manufacturing.

Alban Hutter has been managing the company since October 2017. The construction of a new state-of-the-art 3,000 sqm building with office and assembly areas is in the final stages. Over the course of the year, employees will move from the current location in Grassau to the new building in the municipality of Bergen (both in the Traunstein district).

OPTIMA makes its mark at trade shows in 2018 – both inhouse and across the globe

In 2018, Optima exhibited at around 50 trade shows and table tops throughout the world. One of the highlights was ACHEMA, held in Frankfurt am Main in June, where Optima Pharma received extremely positive feedback for its appearance at the world’s leading trade show for the process industry. The business division impressed visitors with a spectacular 700-sqm booth.

Adopting the slogan “Smart Solutions for Pharma Experts,” Optima Pharma showcased a range of products including flexible filling systems for small batch sizes and a variety of container types, as well as the new digital engineering process CSPE (Comprehensive Scientific Process Engineering), which safely shortens the time elapsing from when an order is placed to when production begins. At ACHEMA, as at many other trade shows, there was a trend towards flexible machine solutions that can react quickly to new market requirements.

Optima Nonwovens raised the concept of an inhouse trade show to the next level in 2018. The trade show, held from June to September, was praised with extremely positive feedback from visitors, who see in-house trade shows and the business division as an effective addition to public trade shows as they focus more on individual customers and their personal needs. This is of benefit to the customers just as much as it is to Optima Nonwovens staff who learn a lot about the needs of customers and can apply visitor feedback directly to new developments.

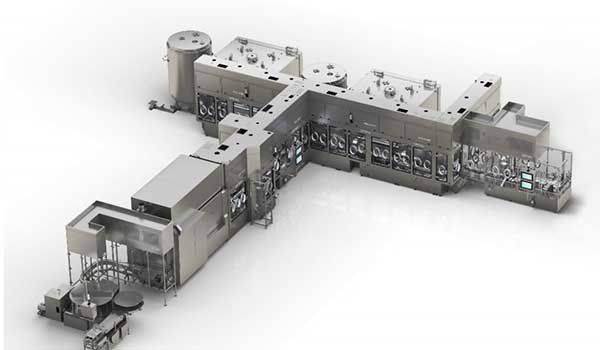

Optima Pharma in Gladenbach-Mornshausen celebrated a major anniversary in 2018 – 25 years of producing ultra-modern freezedrying systems in Hesse. More than 200 guests attended the anniversary celebration. The freeze-drying systems form part of the complete lines that are assembled in Schwäbisch Hall. With the construction of new office and assembly areas for Optima Pharma, the company is underpinning its core competency in the field of turnkey solutions. This allows all system components to be tested and delivered directly in Schwäbisch Hall.

Since February 2018, Joachim Dittrich has proved to be a big asset to the Executive Board in his role as Chairman. The mechanical engineer is responsible for the development and internationalization of Optima Consumer and of further subsidiaries and participating interests. In addition to strategic focus and further development, Dittrich is also responsible for tapping into potentials and synergies. But it wasn’t just the logistics that the company optimized in 2018, the production process was also brought right up to date. Optima procured an ultra-modern laser welding center which produces plates for freeze-drying systems that need to be extremely resistant.

Digitalization – expertise all under one roof

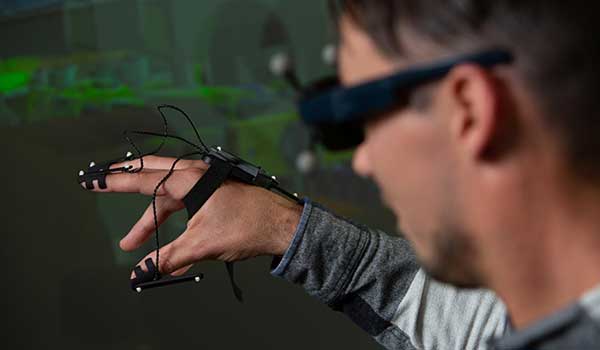

Digitalization has been an established and constantly changing area for virtually all company divisions for many years now. This stretches from administration and customer service right through to production and engineering. Many of these networks and concepts only gained importance along with the “digital revolution”, although line management software OPAL, the servicing software WEmaintain and the intelligent machine condition monitoring system TCAM. The aim is to further increase customers’ use of digital products. Digital solutions offer great opportunities for the Group’s customers when it comes to process reliability, production efficiency, time to market, fast and predictive maintenance, and machine availability. Virtual and augmented reality support various aspects, including the system design stage, the training of system operators, maintenance, and machine operation and renovation.

OPTIMA nonwovens presents the Production of the Future in Miami

In 2019, Optima Nonwovens is showcasing new ideas and solutions for paper hygiene product producers at IDEA in Miami. The courage to pursue new digital technologies is also highlighted in the trade show slogan – “Your Production of the Future: Smart. Efficient. Flexible.” IDEA is the leading trade show for nonwovens and the products produced from it. The Pharma Forum in September is a top-class event that has become firmly established within the pharmaceutical industry. Once again, Optima Pharma is inviting international guest speakers to Schwäbisch Hall to talk to visitors in the Bausparkasse in Schwäbisch Hall about the latest developments and industry trends when it comes to sterile filling and packaging processes. The traditional family day for employees was held in July, which involved machine demonstrations and hands on activities for children and adults alike.

More than 150 apprentices and students working at Optima

In 2018, Optima employed more than 150 apprentices and students from the University of Cooperative Education. Many became aware of the company at the annual “Apprenticeship Night” event. Optima hosted over 680 visitors – more than ever before – at the fourth Apprenticeship Night in September 2018. As part of international “Makeathons”, talented youngsters from all around the world regularly compete against one another and develop solutions for technical issues. The neologism created out of “to make” and “marathon” describes a software and hardware development competition held within a certain period of time. Optima was able to recruit 17 new apprentices from the 2017 to 2019 academic years at junior events such as “DO-IT!” and by supporting robotics clubs at schools in Schwäbisch Hall. This just goes to show that the company is on the right tracks when it comes to supporting young talent. Young people should be enthusiastic about technology in a playful way at an early age.

New offers complement employee benefits

The company is countering the lack of trained specialists proactively, exploring new horizons and using modern channels to recruit qualified staff. Last year, the company rounded off its comprehensive range of offers for employees with corporate benefits – discounts with numerous trading partners – and a corporate employee assistance program.

The corporate employee assistance program offers Optima employees support with difficult personal circumstances, from relationship problems and childcare issues to caring for relatives and financial difficulties. Optima has a social worker on hand as a contact. The pilot scheme in Schwäbisch Hall will be expanded to other locations in Germany, provided employees are on board with the service. The employee assistance service is part of the corporate health management scheme. Optima bears the costs.

The corporate health management scheme includes numerous other preventative measures and events such as health days. These provide the best conditions for a healthy working environment. A staff development program offers numerous opportunities for further development, including through special schemes for agile working in the age of digitalization.

Social engagement in the region and beyond

In 2018, Optima took part in the “Weihnachten im Schuhkarton” (Christmas in a shoe box) project for the first time. Employees put together Christmas packages and the company paid for them to be transported. Kinderhospiz Schwäbisch Hall, Doctors Without Borders, the German National Bone Marrow Donor Registry, the “Herzenswünsche” association and a host of other charities and associations received donations from the company. Optima supports students with “Deutschlandstipendien” (grants).

Short lines of communication, efficient business operations and fast spare parts deliveries. The new Optima logistics center provides the perfect conditions for this.

More than 40 employees from Maier Packaging have strengthened the Optima Group since June 2018. A new building in Bergen (Traunstein district) will be occupied in 2019.

700 sqm, more than 60 Optima experts at the booth each day, international interest. At ACHEMA 2018, Optima Pharma impressed visitors with new technologies and processes for the pharmaceutical sector.

Turnkey setting the trend. The Optima Pharma division in particular has noticed this. The large complete systems, which consist of filling and closing machines and isolator and freeze-drying technologies, take up a lot of space. That is why new office and assembly areas are being created.

In-house trade shows bang on trend. Optima Nonwovens recognized this early on and also put on this type of event in 2018. The concept resonates well with customers as it offers an even more individual form of support.

Optima relies on Smart Services – including OPAL, for example. Production managers in particular benefit from the line management software. OPAL allows them to react quickly to fluctuations in overall equipment efficiency (OEE), as the key production figures are available to them anytime and anywhere.

Total Care Asset Management (TCAM) addresses the needs of machine operators. Information about the machine condition can be displayed along with maintenance instructions. For example, on augmented reality glasses.

At Optima, Virtual Reality is used, among other things, in system design and for training system operators. The Virtual Reality Center of Packaging Valley Germany e.V. offers the best conditions for this.

The commitment of many Optima employees to young talent events such as “DO-IT!” is paying off. 17 new trainees have decided on a future at Optima because of their participation in these events.