interview with Mr M.Nagesh, GM-Yarn Marketing Manager

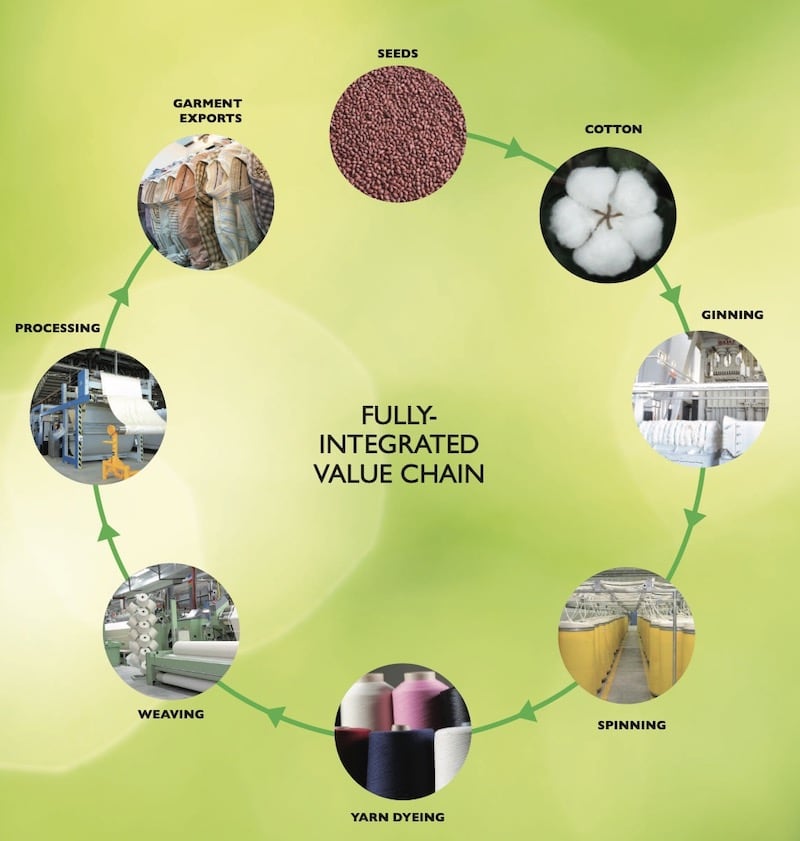

Maybe no textile company in india can claim to be as vertically integrated as NSL Textile is. NSL Textile value chain covers all the operations from the extraction of cotton lint to garment manufacturing. NSL Textile facilities for ginning, spinning, weaving and garmenting are equipped with latest technology machineries and manned by experienced workforce.

Please let us know more details about NSL Textile, history and success story.

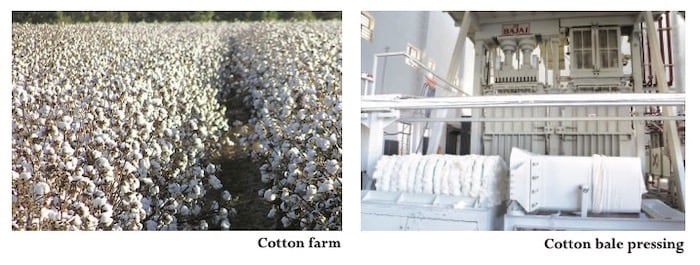

All our cotton spinning facilities are in the high-quality cotton(MCU-5) producing belt in Andhra Pradesh, India. Added to that is the close relationship that NSL group enjoys with the cotton farmers in these regions.

Experience of the parent company(Nuziveedu Seeds Ltd) in cotton-growing has given us the unique advantage in terms of selection of right quality cotton kappas for our own ginning units and thus passing on good quality cotton to our spinning units. Having ginning facilities inside spinning campuses is as an added advantage as ginning operations also taken care by spinning unit in-charges.

Since its inception in 2002 with 27,360 spindles, our spinning capacity has grown multi-folds over years at five different locations in the state of Andhra Pradesh. We have come a long way and emerged as one of largest cotton yarn spinners in the country with installed ring spindles of 275000 and 3744 rotors produces over 100 metric tons of cotton yarn per day ranging from Ne 10s to 80s.

NSL Textiles Ltd is a fully integrated textile conglomerate and the following are production capacities of different divisions.

Ginning – 1800 bales(each bale weighs around 170 kgs) per day

Ring Spinning – 275000 spindles

Open-end spinning – 3744 Rotors

Yarn dyeing – 18 tons per day

Weaving – 630 Airjet looms

Woven fabric processing – 100,000 meters per day

Garments – 13000 shirts per day

NSL has diversified businesses like Seeds, Textiles, Sugars, Power and infrastructure. Our parent company Nuziveedu Seeds Ltd(NSL) is well known in cotton former community as we have over 40% market share in cotton seeds in the country.

Which kind of products you are producing? Which countries are your target market for export? (you can share with us number and figures about your production and export if you like)

- Cotton open-end yarn >>> Ne 10/1, 12/1, 20/1, 26/1 & 30/1

- Carded for Weaving >>> Ne 40s & 60s

- Combed for Knitting >>> Ne 36s, 40s, 50s & 60s

- Combed for Weaving >>> Ne 40s & 60s

- Combed Compact for Weaving >>> Ne 40s, 50s, 60s & 80s

- TFO Doubled Combed for Knitting >>> Ne 36/2 & 40/2

- TFO Doubled Combed for Weaving >>> Ne 40/2, 50/2 & 60/2

- TFO Doubled Combed compact Weaving >>> Ne 40/2, 50/2 & 60/2

- SLUB Combed Cotton Yarn for Weaving >>> Ne 30s, 40, & 50s

- SLUB Combed Cotton Yarn for Knitting >>> Ne 24s, 30s & 40

- SLUB BCI Combed Cotton Yarn for Weaving >>> Ne 30s, 40, & 50s

- SLUB BCI Combed Cotton Yarn for Knitting>>> Ne 24s, 30s & 40s

- Combed Cotton Core-Spun Spandex Yarn Ne 40s & 50s

We can offer both Conventional Indian Cotton Yarn and BCI Cotton Yarn also in all the above-mentioned counts.

We have a good presence in South Korea, Japan, Bangladesh, China, Turkey and Portugal etc.. and looking to grab some market share in markets like Egypt, Latin America, Africa and European countries as well.

How do you evaluate the textile and yarn industry in India in Covid Pandemic period?

As soon as Indian Government announced complete lockdown of entire country, everyone in India as an individual and/or as organization responded positively and extended co-operation to make it a successful lockdown as everyone was under impression that it may last for a week max. But in reality, there were too many extensions of lockdown and textile Industry collapsed literally by looking at the situation all over the world.

By end April 2020 everyone in the industry were under impression that this industry will not recover in 2020. But the industry in fact shown great resiliency and reached back to 100% capacity utilization by mid-September. Yarn markets are performing really good from July 2020 onwards and continuing the same pace even today. Surprised to see such a fast recovery though new cases of COVID-19 are increasing day by day. Compared to countries like China, Indian Textile industry has recovered at a remarkable speed.

As a manufacturer textile Company in India, how do you evaluate the textile and fashion industry in the Middle East and North Africa and its potentials in Future.

COVID 19 shows us we should rely more on sustainability and green products, how do you evaluate sustainable textile and fashion market and its relation to Pandemic?

Sustainability was a major concern for textile industry even before the Pandemic and industry was on its toes for promoting sustainable products since last few decades. Growing acreage of Organic cotton cultivation year by year is best example for this. Organic Cotton production is over 120 million tons as on today with growth rate of over 10% year on year. There are too many aspects which are to be covered under sustainability and green products in textile industry and we need to join hand in hand to move ahead towards sustainability. Pandemic has shown us an illustrative analysis of sustainability’s importance. I think its time for all of us to react fast and try to move ahead in a sustainable way.

Recently India government Start to fund huge investment in the textile industry. How do you evaluate government support for developing India textile sector.

Being an industry which offers 2nd largest employment in the country, the Textile Industry always attracts government’s attention in one aspect or the other. The Indian government is continuously trying to attract new investments in the sector since last few decades. However, there are issues to be addressed by our government. For example, small countries like Bangladesh and Sri Lanka have FTA’s, so that their products enter duty-free in markets like Europe and the USA. India also needs such agreements with few important markets.

Dear Sir

Please see the attachment for my resume.I am working in Kanchan India Ltd .Previously 21 years worked in Nahar. Experience composit Unit Quality& Production in Cotton Ring Spinning 6to110s Combed,Carded, Hosiery,Terry Towel, Weaving,Slub,Lycra,Gassing,TFO,Open End, P/C,P/V,P/M, 100%Polyester,100% Viscose, Slub, Grindle, injection Slub,P/V Dyed Unit.

All type Development, Audit work Fairtrade ,Organic, Grs, Oekotex,Bci.

Thanks & Regards

Santosh Kumar Jaiswal

9814136760

we are interested in giving our company ads in your Magazine as we are manufacturing complete roller covering equipments for the spinning industries in fully automatic as well as semi automatic at present we are exporting our products so many countries in Asia and we want to explore the market through reliable marketing agent for African & Middle east area. We need your support kindly extend by giving your reply as we are in this line since 1980.

Hope to receive your favorable reply and oblige.