Abstract

Cotton is a natural fibre produced in fields. A fruit of Cotton fibres are attached with the seeds. After plucking from cotton plants the fibres along with seeds are processed in ginning. In the ginning machines, main focus is to separate cotton fibres from seeds. But some-how few seeds get crushed and so the cotton along with seed coats & trash is packed in bale form and supplied to the spinning mills.

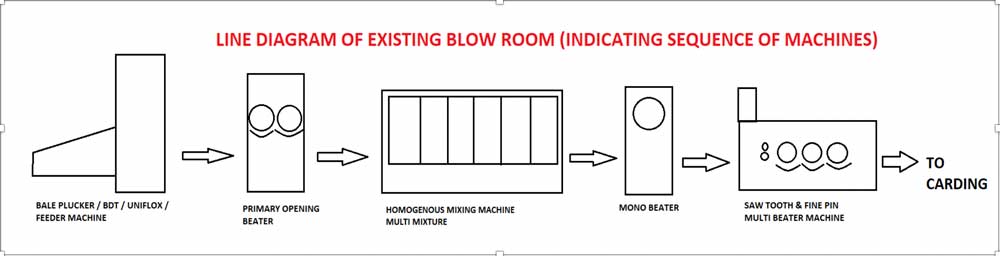

In Cotton Spinning, the first action is managed and controlled by the sequence of machineries known as blow room. The main objective of blow room is to separate good fibres from impurities like – dust, leaves, trash, seed coats & lint. The waste extracted is known as blow room droppings. For spinning good quality of yarn, fibres should be free from these impurities. In general amount of waste extraction is decided on the trash contain in cotton mixing.

Beaters and Air flow are the main components engaged in beating and opening of fibres along with transportation of fibres and removal of impurities. During beating some of the fibres get damaged / broken, and during transportation through air flow some long / short / damaged / immature fibres get converted into a ball form called neps. Neps are the ball formation of fibres created due to entanglement of fibres and may also have tiny size seed coats with it.

So it can be concluded that fibres damage and neps generation are the by product of blow room process and to minimize these issues, there is a continuous development taking place in the machine design and in machinery components.

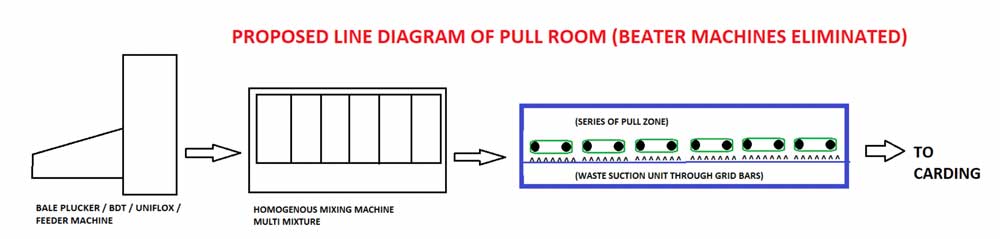

Concept of Pull room effect

If lumps of fibres opened & cleaned without any beating and air transportation it would result into reduced fibre damages & lower neps generations. This will further enhance the yarn quality with lower process flow.

By eliminating the series of existing beating and opening machineries, Pull zone may be introduced. This will solve the main objective of removing impurities and opening of fibres, with ensured lower neps generation and lower fibre damages.

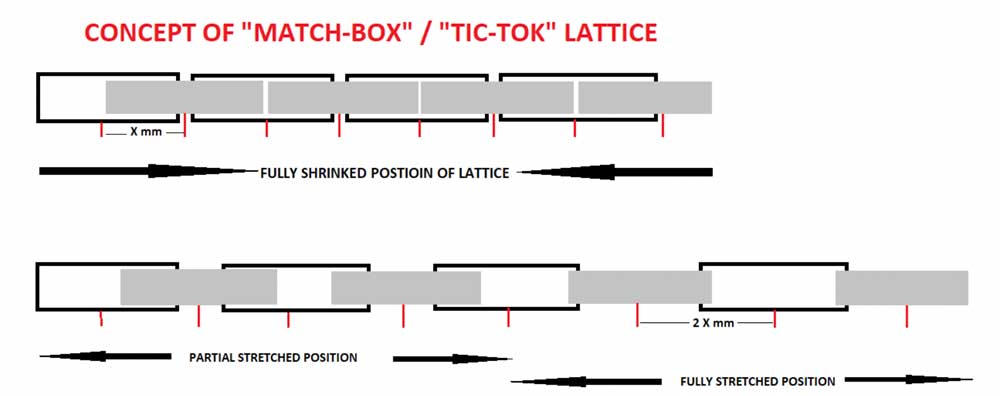

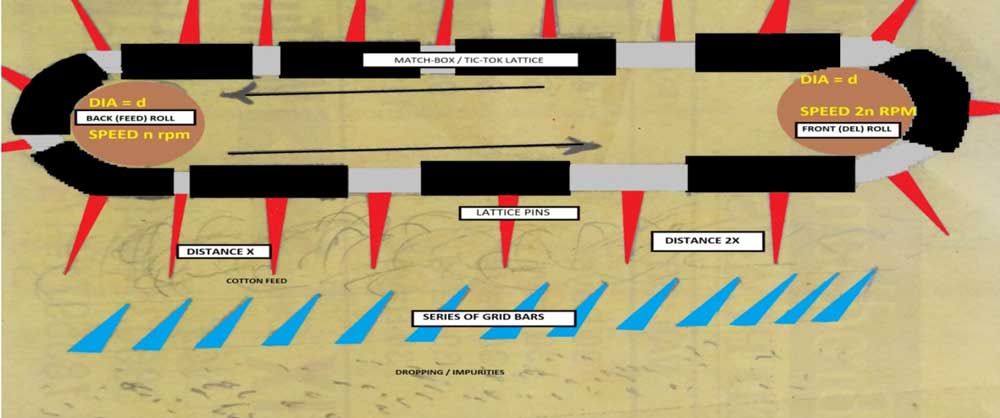

The main component this proposed pull zone is “Match box” / “Tik Tok” lattice, which has a capacity to extend and shrink during its engagement in pull zone. The lattice has pins on its surface which hold the fibres and during stretch, pulls the fibres from the bunch.

The lattice along with the series of pins is mounted over a pair of rolls; the speeds of front roll would be double against the back roll, this introduces draft effect. Therefore the 200% draft is introduced in a pull zone hence the fibres are pulled from each other within the bunch. This results in to the separation of fibres and simultaneously waste gets separated from fibres and is disposed through the series of grid bars.

There can be certain numbers of pull zones. Every pull zone will add 200% draft in the feed material and it can be imagined the total draft in the series of pull zone would separate every fibre without damaging it.

In fabric contamination is considered as a major fault. Mills control these faults by installing various costly machines in blow room and winding. If we closely see we find that in existing blow room one piece of contamination is broken into 100 or 1000 pieces due to the beaters. And these small pieces are tried to arrest by installing contamination / PP cleaners. With this new pull room concept the PP / contamination will not be broken in to small pieces and so there would be better control over contamination / PP in the yarn.

In the existing blow room there is a huge power consumption required to work air supply and the number of beaters. The proposed pull room effect would save huge power as the series of beaters from existing blow room would be eliminated, and also the amount of air suction required for the proposed arrangement would be very low.

Ring Frame: Lower growth in modernization level, an alert to think beyond limitations

By: Ramakant Dubey

+91–8872045777

+91-8872730837