Interview with Tommaso Cumerlato, Chief Sales Officer and shareholder at MIC

Passion, Dedication and Yarn ; All by MIC SPA Since 1911

Tommaso Cumerlato, the fourth generation of the Cumerlato family of Manifattura Italiana Cucirini, after graduating in economics and having worked for other Italian companies in the textile and fashion sector, is now Chief Sales Officer and shareholder at MIC, where he participates in the family’s work together with experienced colleagues in a dynamic climate where, despite the changes in the market and the company, the passion and dedication that the founder possessed at the beginning remains unchanged: MIC is now a reliable company that has always been available to his customers, to follow them and guarantee the quality and service.

Please let us know more details about MIC SPA company, history and success story.

The Cumerlato family’s entry into the world of textiles dates back to 1911, when Giorgio, in the Vicenza area (Italy), founded Ovattificio Cumerlato, to supply wadding to important local clothing manufacturers.

Following a furious fire, in 1940 the factory was moved to Verona, expanding its activity in the field of wool spinning for weaving.

Shortly afterwards, his son Pietro established the company in a new, larger and more modern location in the industrial area of Verona, where ten years later, his sons Piergiorgio and Giovanni set up Manifattura Italiana Cucirini SPA.

With great success MIC entered the Italian market, initially specialising in jeans and casual clothing sector, but the spirit of innovation and flexibility led MIC to be a company capable of progressing and supplying its thread to many sectors of the apparel and clothing world.

Quality and sustainability are key aspects of MIC’s identity and today it’s present throughout Italy with a network of its own warehouses, which are able to supply the goods, ready to be shipped, in just 24/48 hours from the order date.

Distribution abroad was started in the early nineties, following the wave of the delocalisation flows of the most important Italian and European brands.

As a result, important partnerships were signed with the main foreign distributors and direct commercial branches were created from the Baltic countries to the Balkans. Today, with the foreign branches of MIC Africa (Tunis), MIC Albania (Tirana) and MIC Romania (Arad), and thanks to the collaboration with retailers in Poland, Bulgaria, Morocco and the Baltic countries, the company has extended its presence and services to the whole Europe and the Mediterranean basin.

The consecration as a global player and as a group comes with the acquisition of Cometex in Egypt in 2019, a factory of excellence in the production of mercerised cotton for sewing thread and weaving/knitting.

The choice of Egypt is not accidental, as Egypt not only has a reputation as the world’s best producer of high-quality cotton, but logistically it allows us to be close – and therefore quick – to the main brands and clothing manufacturers who have moved their production sites in this continent.

Quality and sustainability are at the heart of the company’s vision, which boasts Oeko-Tex 100 certificates for its products and compliance with REACH specifications, as well as GOTS and GRS certifications for specific products.

Which kind of products do you offer to the market? Which countries are your target market for export? (you can mention number and figures about your production and export if you like)

With over 100 years of experience in textiles, MIC’s core business since 1976 has been the production of sewing threads – more than 60 different articles – for the whole world of fashion and related garments.

Thanks to its in-house dyeing and specialized staff, MIC has become an expert in dyeing different raw materials including polyester, high-quality Egyptian cotton, nylon and others.

Polyester, as the predominant fibre in MIC’s production, is available in numerous variants – spun, core yarn, textured, high tenacity, microfibre and many others – each of these declined in several labels and thicknesses, available in 450 colours, ready in our warehouse to guarantee a fast service of 24/48 hours all over the world, and coverage of all the sectors in which this raw material is used, today available in recycled version too.

MIC cotton is a boast for the company, being produced by the Egyptian production site, which uses high tenacity extra-long staples in the poduction of combed, gassed, mercerised high-quality yarns, which can be dyed on customer’s request.

The production of MIC has also opened up to nylon, in order to guarantee product differentiation for the various needs of the market. In this way we can offer high tenacity polyamide variants, textured and elastic, always dyeable internally in the company respecting all the protocols for a safe and certified production.

Multicolour, antibacterial, water-repellent and recently, antiviral treatments have been developed over the years to offer the most suitable yarn for every need, especially when considered in addition to the presence of technical raw materials such as para and meta-aramid for the production of flame retardant and cut-resistant yarns, threads combining polyester and glass microspheres for reflective effect, and other special yarns for every type of sewing, knitting or weaving and other procedures.

As a leader yarn manufacturer Company in Italy, How do you evaluate the textile and spinning yarn industry in Italy in general and also post Pandemic period?

Art and design are pillars of Italian know-how for which we stand out. Fashion and the entire textile sector are part of it and remain among the sectors that most export all over the world. The improvement of living conditions, the dynamism of the market with the affirmation of historical firms, the birth of new local artisans and international brands, have allowed the whole sector to grow and offer production opportunities all over the world, but in the last few years, it was mainly located in Asia.

Manifattura Italiana Cucirini’s production stands out for its know-how and wants to maintain the quality and the status of Made in Italy, for these reasons it didn’t move its production to the Far East but opened branches in Europe and North Africa to guarantee a rapid and constant service throughout the Mediterranean basin and the European continent.

The crisis caused by the covid-19 pandemic has recently dealt a severe blow to this positive trend in the fashion economy. It required efforts from all sectors, and MIC has been involved, alongside companies in the national territory, in the creation of individual protective devices, giving our contribution to the reconversion to medical devices of several companies in the sector, thanks to the supply of sewing thread already tested for use in sanitary devices.

Among the many companies that have been able to supply this special yarn in a very short time is also the Calzedonia Group, which has been able to produce 150,000 gowns for doctors and paramedics. The pandemic triggered new market demands and required changes in the organisation of many companies, which are starting to return to production in the Mediterranean basin in order to offer a product with less environmental impact and proximity to suppliers of quality products.

We don’t know what will happen, everything changes very quickly, but looking to the future with positivity, we hope that from this difficult time new opportunities for a constant recovery and an increasingly sustainable economy can arise, not including the reshoring effect which will definitely boost the Mediterranean area manufacture and production.

What do you think about the textile and fashion industry in the Middle East and North Africa and its potentials in Future?

In the last thirty years the North African market has become increasingly important for the production of international brands, and today, adding to the positive trend of recent years to the growing phenomenon of reshoring from the Far East (that has dominated it in recent years), we look at this area with positivity for job opportunities, the increasing quality of services and raw materials.

We have also noticed in recent years a trend towards the production of finished garments to be placed on the market and the significant growth of production partners in North Africa, which have gradually evolved from laboratories to companies capable of offering a complete service to the customer, from the design of the garments to the choice of materials. Our presence in these markets is therefore increasingly strategic.

MIC believes in the possibility of growth in this area, witnessed by its presence in Tunisia for over 20 years, its many years of collaboration with production entities in Morocco and the acquisition of Cometex, a company producing high-quality cotton yarns, in Egyptian territory in 2019.

COVID 19 shows us we should rely more on sustainability and green products, MIC Spa has focused on sustainable and organic products as well. how do you evaluate sustainable and Organic textile and fashion market?

This hard times has awakened attention to the organization of the production and supply chain in many brands and fashion realities. For some time now, MIC has turned its attention to a plan to progress, step by step, towards a production that can take into account all aspects of real sustainability: from raw materials and auxiliary products in production, to the avoidance of child and forced labour in its own supply chains, paying attention to geographical presence, in order to reduce its carbon footprint, and constantly improving internal efficiency.

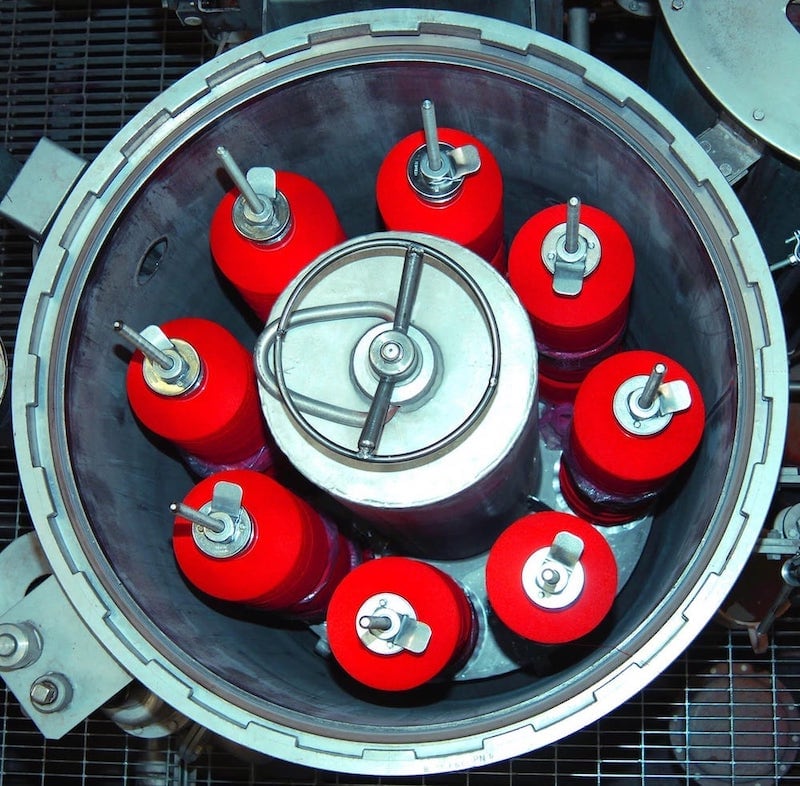

For this reason, as MIC, we have completely renewed the industrial apparatus in 2018, with cutting-edge technologies capable of reducing water consumption in the dyeing phases by 50% and energy consumption by 35%; we have also expanded the purification plant and renovated the photovoltaic system, present since 2011, which since its installation has reduced CO2 emissions into the atmosphere by 860 tons – the equivalent of planting 2. 200 trees.

The new market requirements and MIC’s research and development department, have made this new focus an opportunity, following this path MIC added eco-friendly articles to its product range:

Recycled high-quality polyester, ICEA-certified GRS line, increasingly in demand and needed by the market, also available in numerous titles and variants, that over time will replace the offer of standard polyester to ensure a useful service to the fashion industry, man and the environment.

Biodegradable nylon, LEAF – available in textured sewing version, for productions that use this sustainable technical material born from the research of companies outside MIC to cover all market needs;

Organic cotton, BIO-COTTON, dyeable in many colors and available in the MIC product range since 2007 and the first sewing thread in the world to be GOTS certified, in order to guarantee the traceability of production in compliance with the most current organic farming regulations, which guarantee the absence of synthetic pesticides from sowing to fibre harvesting, and do not allow the use of forced or child labour, and even verify and approve all the substances and processes for the production of the finished product.

For More information and Free Samples contact :

MIC – Manifattura Italiana Cucirini SPA

Via Spineta, n.61

37050 Vallese di Oppeano – Verona

Phone: +39 045 7134725

FAX: +39 045 7134104

E-mail: mic@micspa.com

Thanks for sharing

I’m tumo molahlehi from KTM and mohair BROKER PTY LTD lesotho we’re in the raw greasy wool business so we’re looking for the buyer method of payment we need L/C we can supply from one 40feet container upwards for more information call CEO directly or watsup here +26658505586/email tumoph@gmail.com

Hello,

I am from pakistan.i am interested in your deyed cotton yarn.plz send me detail and price which cotton count you offer?

Hello sir, I am Niraj from India. I need towel febric,240-250gsm.