New version of the DISCTENS disc-type yarn tensioner offers even better performance

KARL MAYER’s yarn tensioners reliably guarantee a constant yarn tension over the entire length and width of the warp when yarn drawing-off during the warp preparation process – from the first metre to the last. They protect the yarn material and ensure a long service life.

The yarn tensioners are also extremely wear-resistant, even in the face of the high loads exerted by yarns that can be fast running and even aggressive.

In order to help customers regulate the tension when working cotton yarns, particularly for denim and applications that require coarse gauges, KARL MAYER offers the DISCTENS model.

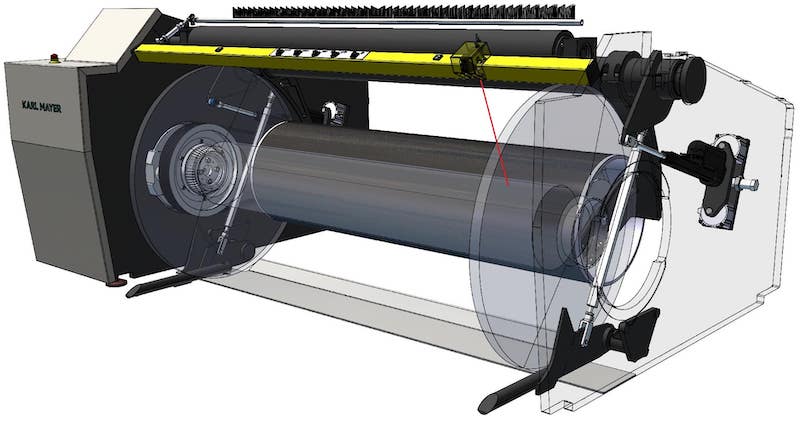

This high-precision, electromagnetic, disc-type yarn tensioner is a tried-and-tested product that has proven its worth in many applications, especially when used in tandem with the KARL MAYER BALL WARPER. The new ISO COTTON direct warping machine also provides optimum benefits when used with the DISCTENS. This year, the high-precision yarn tensioner has been given an upgrade that boosts its performance even further.

The DISCTENS is perfect for prcessing yarns with a wide range of gauges. Its reliable gauge range is 30% larger than that of comparable models. It can work cotton yarns with counts of 4 to 100 Ne at the necessary tensions without any problems at all.

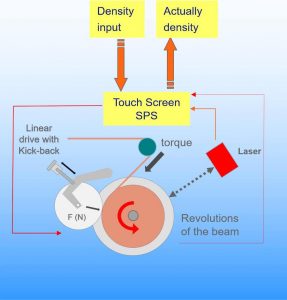

Its tension range runs from 3 cN to 95 cN. In order to ensure maximum flexibility, the DISCTENS uses a pair of discs and the force of electromagnetic attraction. One of the two disc elements – which are positioned opposite one another – is made of brass, the other of steel. When a magnetic field is generated, the gap between the discs becomes smaller and the yarn tension increases.

During this process, the magnetic force – and thus the yarn tension – is regulated digitally with an extremely high level of precision. This is done for all package positions. Each thread of the creel is controlled by one DISCTENS.

Self-cleaning solution

In order to ensure efficient removal of soiling, the discs are driven in the let-off direction of the yarn by a motor and arranged vertically – rather than horizontally, as in most other yarn tensioners. This means that any dirt can simply fall to the ground and does not need to be blown off the discs.

However, this motor only runs when it is needed. An optical sensor is used to check that the threads are present and moving correctly, and triggers an automatic stop if these two requirements are no longer being met. This double-check is necessary because the yarns in the unused package position are often knotted when the number of threads is altered frequently, i.e. they are still in play but not being moved.

For materials that are particularly prone to linting, the DISCTENS can be fitted with an optional, built-in blower nozzle.

Easy input thanks to uniform operator interface

The DISCTENS can be used on all KARL MAYER GH-series creel types. It is fully integrated into KARL MAYER’s PLC architecture and the operator interface used on its warp preparation systems, which is a benefit that cannot be matched by third-party alternatives.

This means that all the machine operator needs to do in order to set up the DISCTENS before commencing operation is to enter the yarn count via the warp preparation system’s operator interface. No additional displays or data input are required. The system automatically derives and calculates all the other figures it needs, such as the yarn tension, based on this information.

All the key process information at a glance

In addition to allowing data input, the display also outputs all the information required. One of the factors included in this output is the “Learned/Not learned” status, which indicates when the target number of threads entered by the user does not match the actual number present. If a thread is missing, the display indicates where it should be using information received from the yarn tensioner.

The operator interface also provides notifications in case of yarn breaks. If a thread tears, the effective communication via the machine’s computer system brings operation to a stop extremely quickly. KARL MAYER’s proven opto-electronic Stop-Motion-Sensors ensure that yarn breaks are detected quickly and reliably.

Another type of information output by the system is the yarn tension. Differences in tension at various stages, such as during putting into operation , can be adjusted separately using the “Calibrate” service menu on the touchscreen to ensure that each position is exactly correct. On older systems, each individual position had to be adjusted using a tool.