Sustainability is a huge element that has made its way into the global retail industry and India too is resistant to sit back now. While the overall fashion retail industry is going sustainable, denims particularly interests us with the overall size of this segment growing phenomenally and the recent movement of denim brands towards sustainable manufacturing.

India is the fifth largest destination in the global retail space, making the Indian apparel industry the second largest contributor in the retail sector. According to recent industry reports, denim is the single most leading segment in the fashion industry.

Manjula Gandhi, Chief Product Officer, Numero Uno, asserts, “A good pair of jeans is an important element of a modern day wardrobe which is fashionable, durable and versatile. For this reason, denim has always reigned as one of the leading apparel segments in the Indian fashion industry. Despite slowdown of domestic market growth as well as apparel exports, denim market in India has been clocking a consistent CAGR of 15-18 percent year on year. The industry’s future looks promising as well.”

While the industry is growing with approximately 6 billion pairs of jeans being sold around the world every year and is foreseeing a flourishing scenario in denim business, the denim brands around the world are facing pressure to change the methods of manufacturing jeans in order to tackle environmental issues.

Large amounts of greenhouse gases are released from the manufacturing process of denim, but this was true even in the past. So what exactly has changed and what made sustainability a major factor for the denim industry? Let’s find out.

What’s Driving the Sustainability Movement?

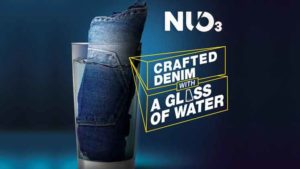

The production of denim can be resource intensive, i.e. , it uses incredible amounts of water and toxic dyes while manufacturing one of the world’s most purchased pieces of cloth – denim. On an average, it takes about 70 litres of water to make a pair of jeans from the denim fabric, but the times have changed and manufacturers as well as brands are innovating their ways and have reduced its water footprint to make jeans by over 95 percent.

A lot of factors, besides the ethical reasons, are forcing the denim manufacturers to go green. Kavindra Mishra, Managing Director, Pepe Jeans India, maintains, “Pepe Jeans has long understood the importance of sustainability in its production process, taking its eco-conscious focus as seriously as its designs for the future of denim. Innovation and knowledge is at the heart of Pepe Jeans. Its leading denim laboratory always strives towards the best in design, style and operation. Pepe Jeans is not only setting the standard in denim design but in eco-technology. Through this, we aim to let indigo thinking become synonymous with green thinking when it comes to your own wardrobe. We have introduced the sustainable range of denims in all our stores pan India which further proves our commitment towards sustainable products that will soon be our future.”

The factors driving this change include changing values of society– durability and sustainability becoming increasingly important especially among young people. Besides, customers are paying attention and 93 percent of global consumers expect their brands to support social and environmental issues and so the retailers and manufacturers are complying. Manjula Gandhi from Numero Uno adds, “It is no longer enough for fashion companies to talk about their green ambitions, they have to prove that they are taking actual steps in making their practices greener and more ethical.

Numero Uno has always been an eco-conscious and responsible brand with emphasis on low water consumption, restricted use of hazardous chemicals and good working conditions for its workforce.” The core consumer group for this range is the new age millennial who are aware and motivated by concerns which are for their personal well being as well as of global consideration.

The Back-end Processes

Given the growing concerns around sustainability, denim brands have realized that it is not just a trend but progressively becoming a prerequisite to sustain themselves in future. Samita Singh, Head- Design, Wrangler, apprises, “In Wrangler, we have already started our journey to become one of the leading sustainable denim brands. Besides using sustainable/recyclable materials, we are also working on practices like ethical cotton sourcing, which results in giving back a fair amount deserved by farmers. The contribution is small as of now but increasing steadily with each season.”

While a number of denim brands are working towards going sustainable, what exactly goes into the entire process? For Pepe Jeans, the first stage always includes R&D of ways of producing eco-friendly denims. The brand’s collection called Wiser Wash involves process that eliminates the use of pumice stones and toxic chemicals which are involved in traditional washing. “While this takes away the hazard, it still retains the bright contrast and the abrasions that brings about the true depth of indigo coloured denims. This entire process is done using less than a cup of water. When creating this collection, our main priority was to ensure that no chemicals are disposed of in the environment during the denim washing process. This method also increases the lifespan of the denim as there is less damage to the cotton fibres; thereby preserving the natural state of fabric. Lastly, the garment is free of residue that comes from corrosive chemicals that also gives a better environment for workers,” boasts Kavindra Mishra.

Numero Uno involves a combination of multiple processes involving use of laser technology, ozone treatment with minimal water and chemical usage to achieve the desired final output, with no compromise on the design aesthetics of the denims.

Even as the price range of sustainably manufactured denim is comparatively higher in comparison to the other collections, brands are looking forward to the sustainable collection to bring in nominal amount of sales and are building up on these collections. The price range of sustainable merchandise by Wrangler starts from Rs.3,000 and goes up to Rs.4,000; for Pepe Jeans it ranges between Rs.4,999- Rs.5,999; and the One Glass Water Jeans collection by Numero Uno is priced between Rs.2,699- Rs.2,799.

Sustainable in Hinterlands?

The global jeans market is valued at US $ 92.9 billion, according to Euromonitor. It is the fastest growing segment in majority parts of India. But is it true for the sustainable denims collection as well? We agree that the consumer psychographics across tier-I, -II and -III vary widely and while tier-I and -II markets are aware and are demanding sustainable denim collections, tier-III market is yet to expand its avenues for eco-friendly merchandise. However, major players in the segment feel that sustainability and environment conscious lifestyle will trickle down to tier-II and tier-III areas in the times to come.

Pepe Jeans has already launched two lines of eco- friendly denims called Wiser Wash and Post Consumer Waste denim and plans to start communicating and educating its customers on its sustainable line of products through digital channels. From futuristic denim technology brands to handloom ones like ikat, denim is witnessing a revolution in terms of design aesthetics and accessibility to cater to the evolving mentality of the consumers. Even one of the country’s largest denim producers, Arvind Ltd., is untouched by this development and has implemented the Zero Liquid Discharge (ZLD) technology at its treatment plant.

Moving forward, Numero Uno is planning to enlarge its portfolio of sustainable denim collections and continue producing sustainably, avoiding waste or spoiling resources, conserving energy and reducing harmful toxic chemicals during washing processes. Fortunately, many denim manufacturers and retailers are striving to embrace greener methods and are also making efforts to develop new techniques of producing jeans sustainably and the trend is very efficiently getting trickled down to the supply chain and the manufacturers in different countries.