The ideal machine for mass production of simple articles, such as sportswear accessories and bands for technical articles.

Beside the innovations on our electronical knitting machines, COMEZ continued in the study and development of numerous machines models with mechanical control to improve their efficiency, productivity and easy operations.

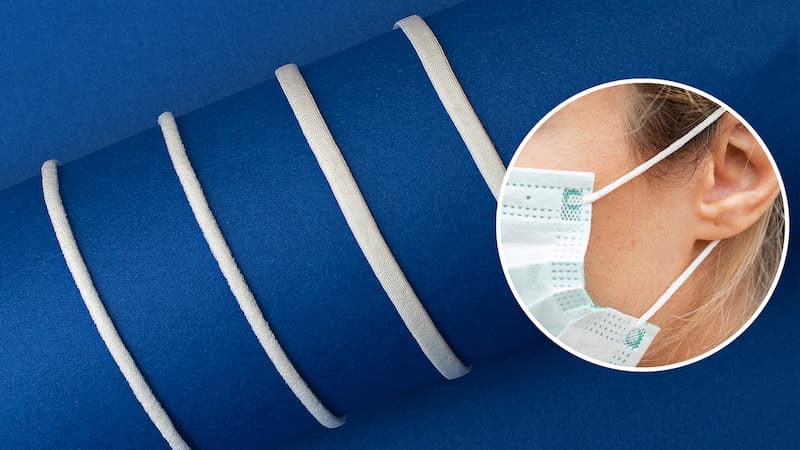

The result of this ongoing research is the new DNB/600-2B, a high-speed mechanical warp knitting machine with double-needle bed, suitable for the mass production of simple articles, such as bands for sportswear.

The machine is equipped with 2 mechanically controlled guide bars and can process any type of yarn, both synthetic and natural, according to the machine gauge. In addition, the two-needle beds and guide bars allow the production of double face fabric structures.

The DNB/600-2B machine enables very high productivity, thanks to its operating speed and the low stitch density value required by fabrics produced. Its compact design and reduced working width allow fast article changeovers, in both small and long production runs.

Users of COMEZ machines are in a position to obtain high-quality products in large quantities. They can therefore count on continuous production (overcoming changes in fashion tastes and market trends), enabling them to also be competitive in new market segments.

Notable features of the DNB/600-2B:

> high efficiency and operating speeds

> simple structure

> easy operation and maintenance

The primary application sectors for articles produced on this warp knitting machine are sportswear accessories and technical articles.

For more information, or to view samples produced on our machines, please contact our agents or the COMEZ Sales Area Manager responsible for your country.