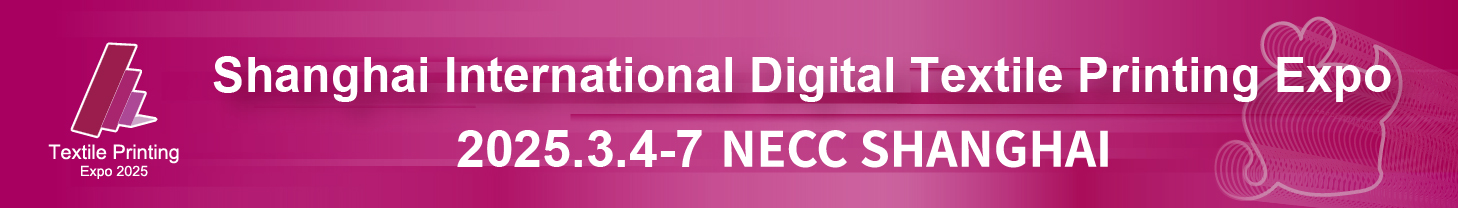

THE WASTEFUL LIFE OF OUR CLOTHES

- Global textiles production almost doubled between 2000 and 2015, while the number of uses per item decreased by 36%.

- Up to 10% of global GHG emissions originate from the textile sector.

- Plastic is projected to overuse the carbon budget available for the sector 5 times by 2050.

STEP 1: EXTRACTION OF MATERIAL

The incredible volumes of clothes produced is enabled by cheap synthetic Fibres – mostly polyester, which is found in over half of all textiles produced. Most recycled content in clothes today originates from PET bottles which, instead of being recycled into bottles, are downcycled into clothes.

STEP 2: DESIGN

At the design stage demand for fast fashion is created via replication of social media and high fashion trends.

STEP 3: PRODUCTION

During the accelerated manufacturing cycles abuse of human and labour rights, child labour, health and safety issues, as well as industrial accidents remain commonplace.

STEP 4: MARKETING

Aggressive marketing and convenient deliveries result in 10%60% of produced clothing going unsold or being sold at a discount. 20%-30% of online purchases are returned and often end up being destroyed rather than put back on sale.

STEP 5: CONSUMPTION

Wardrobes are replaced frequently by new fast fashion items that quickly become unfashionable or damaged because of poor quality. Every year, almost 26 kg of textiles per inhabitant are consumed in Europe, with 42% of these becoming waste, amounting to ll kg of clothes per person per year.

STEP 6: CONSUMPTION

Every second, the equivalent of a truck load of clothes is burnt or buried in a landfill. Textile-to-textile recycling rates are around 1%.

Textiles are one of the main sources of microFibers in the oceans.

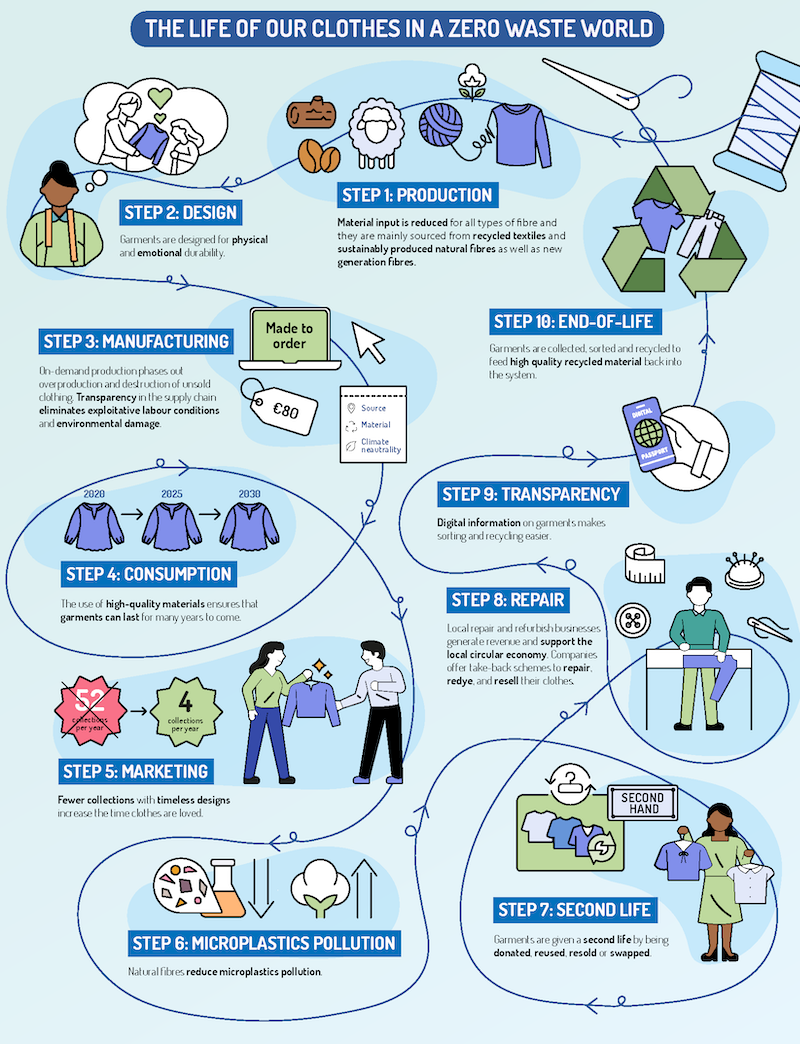

THE LIFE OF OUR CLOTHES IN A ZERO WASTE WORLD

STEP 1: PRODUCTION

Material input is reduced for all types of fibre and they are mainly sourced from recycled textiles and sustainably produced natural Fibres as well as new generation Fibres.

STEP 2: DESIGN

Garments are designed for physical and emotional durability.

STEP 3: MANUFACTURING

On-demand production phases out overproduction and destruction of unsold clothing. Transparency in the supply chain eliminates exploitative labour conditions and environmental damage.

STEP 4: CONSUMPTION

The use of high-quality materials ensures that garments can last for many years to come.

STEP 5: MARKETING

Fewer collections with timeless designs increase the time clothes are loved.

STEP 6: MICROPLASTIC POLLUTION

Natural fibres reduce microplastic pollution.

STEP 7: SECOND LIFE

Garments are given a second life by being donated, reused, resold or swapped.

STEP 8: REPAIR

Local repair and refurbish businesses generate revenue and support the local circular economy. Companies offer take-back schemes to repair, redye, and resell their clothes.

STEP 9: TRANSPARENCY

Digital information on garments makes sorting and recycling easier.

STEP 10: END-OF-LIFE

Garments are collected, sorted and recycled to feed high quality recycled material back into the system.

Source: zerowasteeurope.eu