The Renewable Carbon Initiative has published a position paper outlining the importance of chemical and physical recycling and what is needed to realise its huge potential.

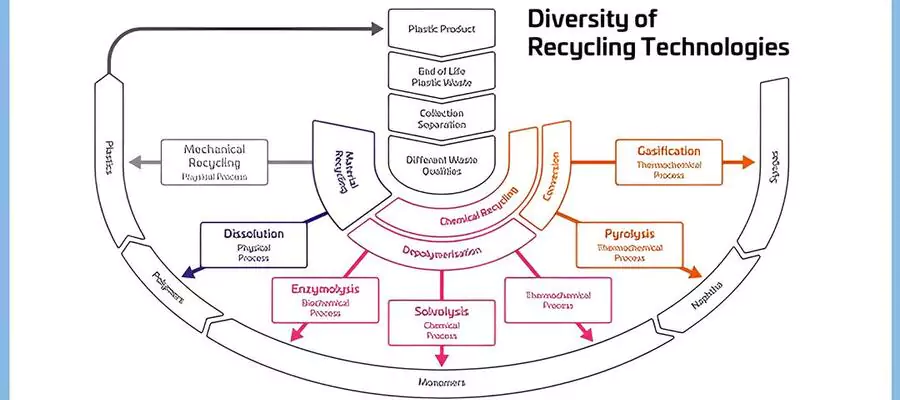

Chemical and physical recycling play essential roles in realising the objectives of the Green Deal and advancing the circular economy. These technologies are indispensable for the green transition. A wider range of different chemical and physical recycling processes are needed to keep as much of the carbon embedded in plastics as possible in the cycle.

Through this, the required volumes and scalability of the circular economy can be achieved. Chemical and physical recycling enable the utilisation of waste streams that cannot be mechanically recycled and are currently sent to incineration or landfill. They are the only ways to ensure these materials remain in a cycle, reducing reliance on disposal methods like incineration and landfill.

Mechanical, physical, and chemical recycling complement each other due to differences in available waste stream composition, sorting needs, target products and economics. Each technology has distinct strengths and weaknesses in terms of input, output quality and quantity.

Chemical and physical recycling are fundamental for a comprehensive carbon management that creates sustainable carbon cycles and enables the defossilisation of the chemical industry. While they hold considerable high-volume potential, significant investment is needed to fully leverage these technologies. Creating secure demand, in particular through the policy framework, is imperative to achieve this.

What is necessary to realise the huge potential of chemical and physical recycling?

In its latest position paper, the Renewable Carbon Initiative (RCI) identifies eleven requirements to create secure demand, drive investment and further improve the technology field. These include general acceptance of the technology; mandatory recycled content for all polymers/plastics in all applications; recognition and clarification of rules for the calculation of recycling rates;

full acceptance of mass balance & attribution with fuel-use excluded; accelerated approval of new chemical and physical recycling facilities; expansion of recycling infrastructure for all sectors beyond packaging; and the extension of CO2 pricing for waste incineration in the ETS combined with a landfill ban.

Additionally, RCI advocates for a pragmatic approach, emphasising that while closed-loop recycling is a noble goal for sectors such as packaging, textiles and automobiles, it should not be approached too dogmatically. Flexibility is essential to prevent environmental and economic inefficiencies. If the waste stream of one sector can be better used in another, this should be possible.

Comprehensive Carbon Management

Chemical and physical recycling emerge as key technologies and critical component of a comprehensive carbon management. Carbon management goes beyond the reduction of CO2 emissions and their capture and long-term storage. It decouples the entire industry from fossil feedstocks from the ground, eliminates the use of fossil carbon wherever possible and allocates renewable carbon from biomass, CO2 and recycling as efficiently and effectively as possible where carbon use is unavoidable, like chemicals and plastics.