This year Dilo Systems will participate in different exhibitions for the textile and nonwovens industry.

As a machine manufacturer, Dilo Systems provides production lines for any nonwoven process and all types of staple fibre products. All over the world, Dilo lines produce nonwovens for a wide range of applications including geotextiles, housing and roofing, automotive products, filtration, acoustics, artificial leather, and medical or hygiene products.

The Dilo Group is traditionally successful with innovative technical solutions that continuously increase the product quality, efficiency, and sustainability of our production lines.

3D-Lofter Technology

For example, the 3D Lofter technology is adding numerous possibilities to nonwovens. It works like a 3D – printer whose ink consists of fibers and the addition of adjustable amounts of fiber in a specific pattern on top of fiber mats or needled felts enables applications like decorative features, precise reinforcement or improved fiber mat quality. Furthermore, nearly all fibers like PES, carbon or natural fibers are usable.

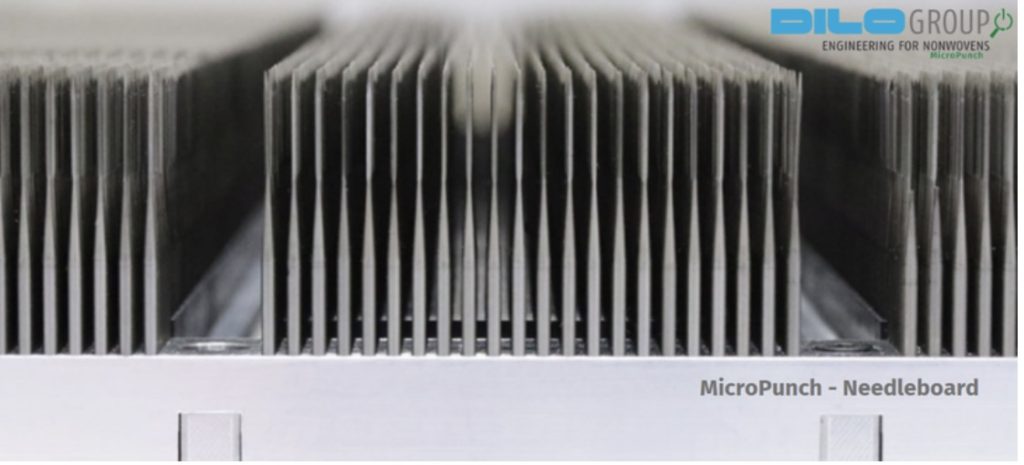

Intensive Needling Technology “MicroPunch”

Our latest needling innovation “MicroPunch“ is a green needling technology for the production of lightweights with similar characteristics to hydroentangled nonwovens. A big advantage is the reduction of power installed up to ca. 75%. This production line is particularly suitable for processing fine fibers of polypropylene, polyester, and viscose.

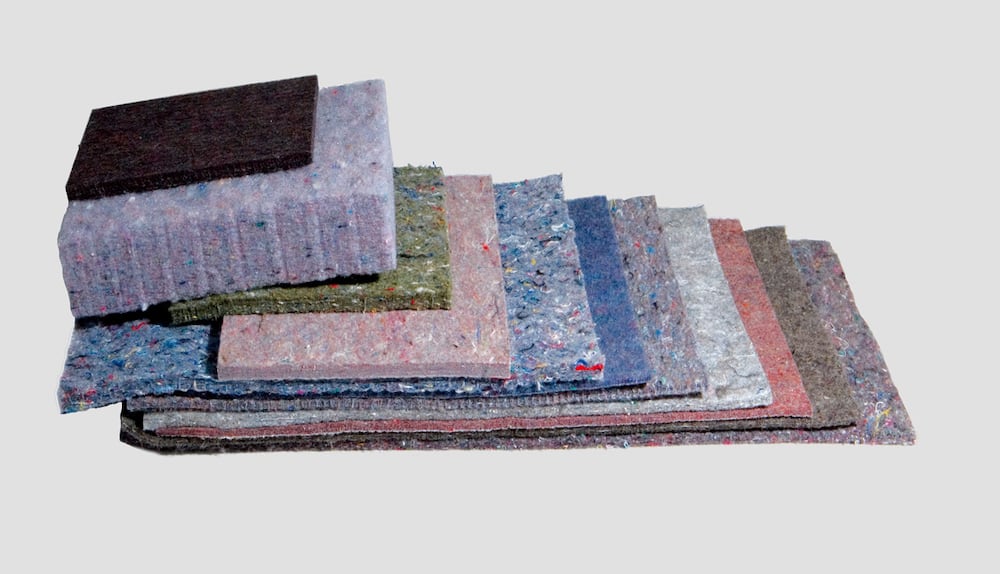

Textile Recycling

Dilo Systems offers complete nonwoven production lines to recycle textile waste through the cooperation with Dell’Orco & Villani and Techno plants and will thus cover the complete technology area for regaining fiber, web formation, needling, thermal bonding, end-of-line components and dedusting.

The lines will be offered according to the proven Dilo standard for automation and drive technology. The projects will be handled turnkey by DiloSystems as a general contractor.

Our engineering is thus supported by four demonstration, testing and development centers for the various process stages to provide all necessary information before investment decisions.

We look forward to welcoming you to the following exhibitions this year:

DTG, Bangladesh: 1. Feb – 4. Feb Hall 8, booth 8-839

Exintex, Mexico: 27. Feb – 01.March booth 812

Saigontex, Vietnam : 10. Apr – 13. Apr Hall A, booth 1J11

Techtextil, Frankfurt: 23.Apr – 26. Apr Hall 12.0, booth B81

Anex, Taiwan: 22. May – 24. May Hall 1, booth J139

ITM, Türkiye: 04.06. – 08.06. Hall 3, booth 310A

Dilo Group’s Professional Performance at ITMA with MicroPunch Technology