Saurer looks forward to welcoming customers at the Egy Stitch and Tex 2024 exhibition in Cairo, Egypt, at the ATAG booth 5E14 in hall 5. Supporting our customers in Egypt, Africa, and the Middle East with our future-oriented solutions in the areas of sustainability, digitalization, and automation is Saurer’s goal. Experience the ZI 72XL compact-spinning machine – running live on the booth.

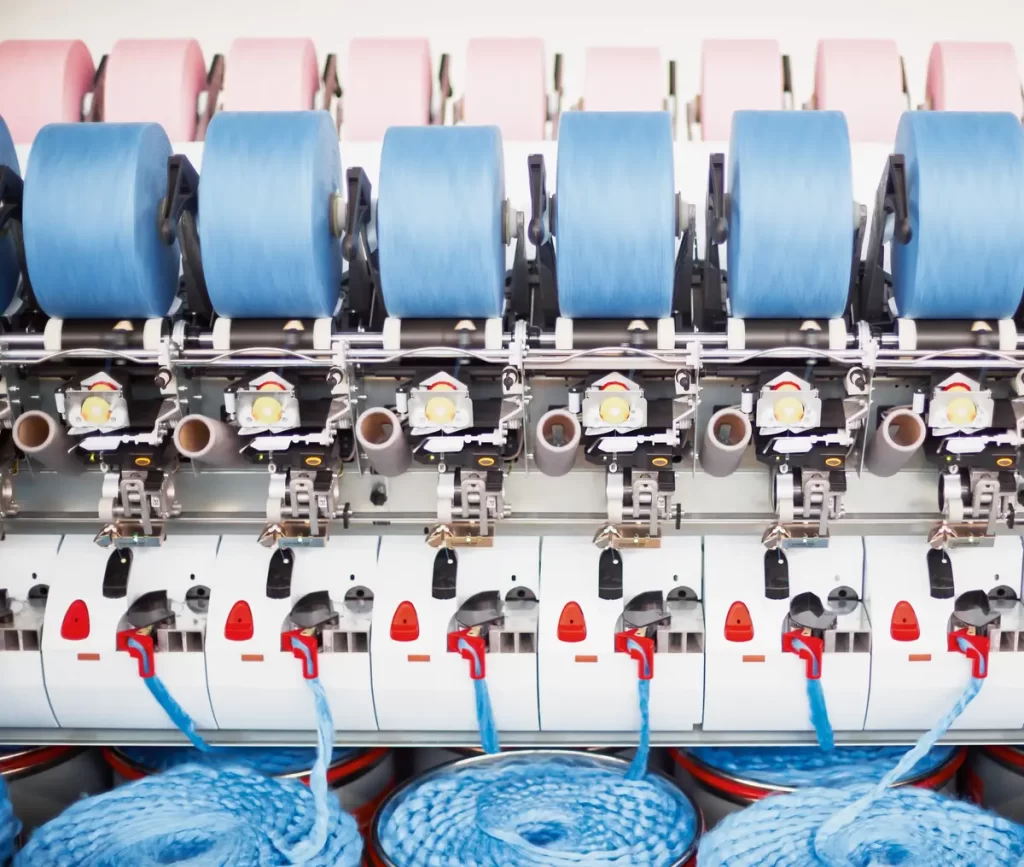

Saurer is the pioneer for sustainable and economical solutions in ring-spinning and will present the highly productive ZI 72XL compact-spinning machine in Egypt. The ZI 72XL offers a high degree of flexibility for almost all applications and is suitable for recycling fibers. Featuring the new self-cleaning compact yarn system Impact FX pro with multi-hole aprons, the ZI 72XL delivers excellent yarn values for standard and recycled yarns, especially for fine yarns.

Rising energy costs are forcing us all to take action. The new Texparts Eshape spindle has a reduced wharves diameter of 17.5mm, which enables remarkable energy savings of up to 6%. The Escape spindle is installed on the ZI 72XL and shown in running condition.

The Saurer experts at the booth will welcome you to discuss the latest innovations of the all-new product portfolio presented last year at ITMA Milano and ITMA Asia. With its focus on automation, digitization and ergonomics, the new Autocard SC7 M assists spinning mills to obtain more production and higher quality with less labor.

Our rotor spinning portfolio has been upgraded to process even the shortest fibers with the Autocoro 11 in the Recycling Xtreme version and the semi-automatic rotor spinning machine BD 8 is now offering a doffer as an option. The Autoairo air spinning machine from Saurer sets new benchmarks for productivity, automation and efficiency for economical air spinning and is now processing cotton.

With the Texparts product line, Saurer offers high-quality components for the textile industry including drafting systems and spindles, spinning rings and travelers, as well as bearings for ring-spinning and rotor-spinning, winders and twisters. The Texparts components ensure excellent yarn quality, maximum productivity and with some products also energy savings.

Sustainability also implies longer product life. SUN-Service Unlimited offers solutions for the long and sustainable life of Saurer spinning machines as well as upgrade kits for processing recycled fibres. Additionally, Saurer provides solutions to improve the energy efficiency of your current machinery.

About Saurer Group

The Saurer Group, founded in 1853, is a leading, globally active technology company with a focus on machines and components for yarn production. As a company with a long tradition, we have always been an innovation leader. Today, the group is a solution provider for the textile industry consisting of two segments.

Spinning Solutions offers high-quality, technologically advanced, and customer-specific automated solutions for staple fiber processing from bale to yarn.

Saurer Technologies specializes in intelligent and economical twisting and cabling machines for tire cords, carpets, staple fibre, glass filament and industrial yarns, which allow customers to adapt flexibly to dynamic market requirements. Automation Solutions provides textile mills with an array of labor-saving systems. With around 3,300 employees, the Saurer Group, with locations in Switzerland, Germany, France, the UK, Czech Republic, Turkey, Brazil, Mexico, the USA, China, India, Uzbekistan, and Singapore, is well equipped to serve the world’s textile centers.