By Mohammad Esmail Sharifkhani

Since the output of the Blowing line is a disordered and Nep-included bulk of entangled fibers and still has impurities to some extent, it is necessary to extract remaining dust and fragments, non-functional or broken fibers and other foreign elements.

This goal is accomplished by carding machine. Carding is the procedure of forceful opening, cleaning, paralleling and individualizing of fiber via mechanical work. The delivery is the “sliver” which is defined as a thick strand of untwisted and straightened fibers quantified in a uniform linear weight and coiled appropriately for the following process.

To produce a quality end yarn, carding is an essential step for all long or short staple fibers. This process is associated with the reduction of fiber entanglement. Furthermore, the Nep content of yarn is strongly dependent upon the effectiveness of the carding. The basis relies on passing in progress materials through surfaces which are closely-spaced and sharply clothed or needled.

Inasmuch as the quality of yarn is directly tied to sliver quality, the specialists know the carding as “the heart of spinning and taken into consideration as nicely carded is half spun”. This indicates an affirmation and an emphasis on its significance in staple spinning.

The innovations in the carding systems are growing and getting promoted uninterruptedly and replacing the previous technologies. These modernizations enable operators to achieve higher quality and quantity within lower cost and energy. In this article we aim to generally cover the latest advancements in the carding machine.

The processes in Carding Machine

• Combing between feeding roller and taker-in.

• Carding between main cylinder and revolving flats.

• Stripping firstly between taker-in and main cylinder and secondly between doffer and stripper.

• Doffing between main cylinder and doffer.

The main functions and tasks of Carding Machine:

• Opening the chute fed fibers and individualizing

• discarding dust, trash and seed coat fragments

• removing non-spinnable and hairiness-raiser fibers

• extracting Nep

• material blending

• material straightening or alignment

• Web formation

• Even slivering

Assembly units of a Carding machine

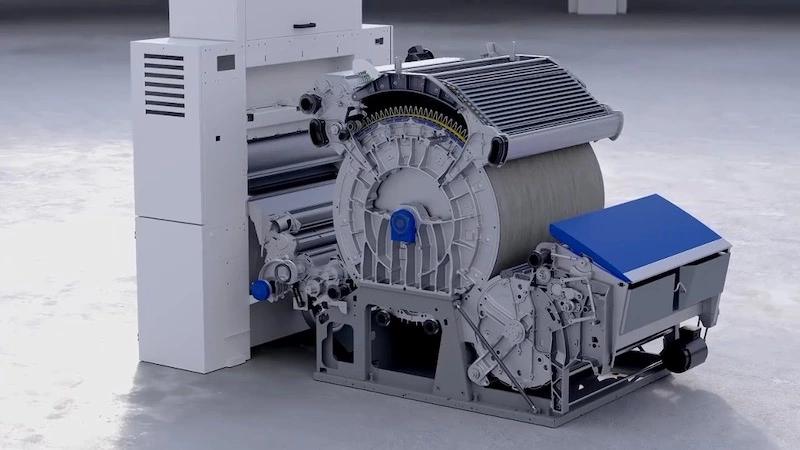

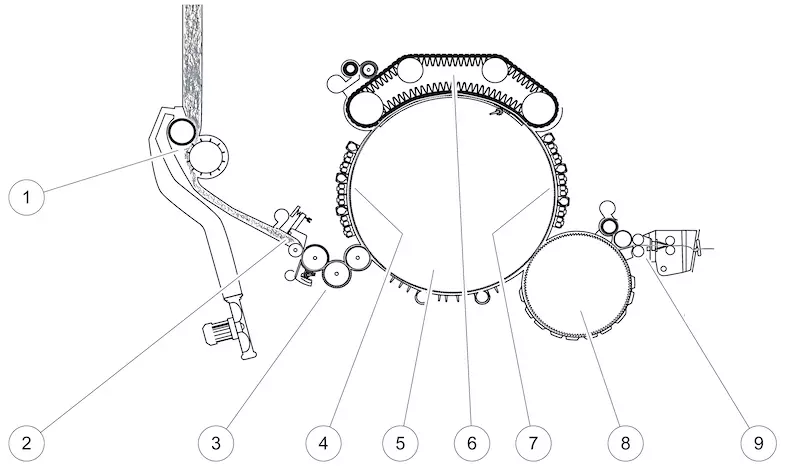

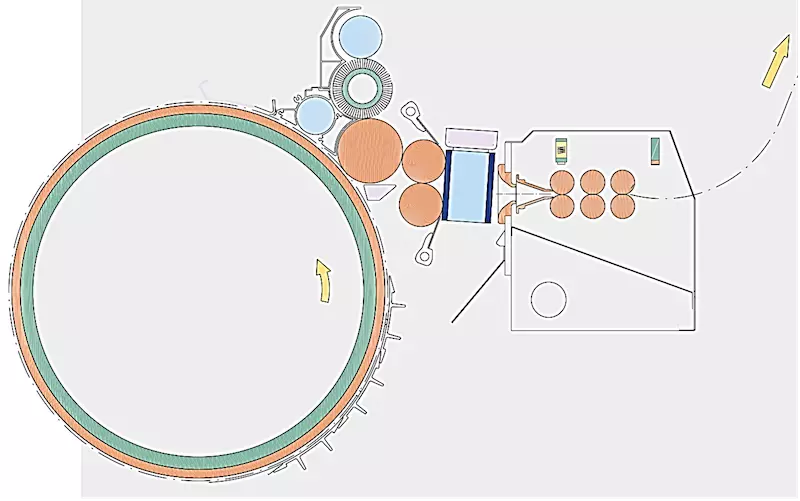

Carding machine primarily comprises feeding section, taker-in (or licker-in), main cylinder and a set of revolving flat-bars, doffer and stripper. They have needles or wires on the surface. The illustration below shows the units of a Truetzschler “TC 10”. The parts are named according to the manufacturer’s catalogue.

• tuft feeder

• integral tray and feed roller

• licker-in unit, (1 or 3 rolls)

• Pre-Carding area with fixed flats

• main Cylinder

• Revolving flats

• Post-carding area with fixed flats

• Doffer section

• Web doffing section

The technological improvements in Carding machine

• Delivery capacity around 270 kgs per hour

• Feed rate monitoring

• Direct feeding and supply system via Chute feed

• Metals detectors

• Triple licker-in unit

• Build-in and continuous suctioning

• Magnetic revolving flats: MAGNOTOP

• computerized control via Touch Screen

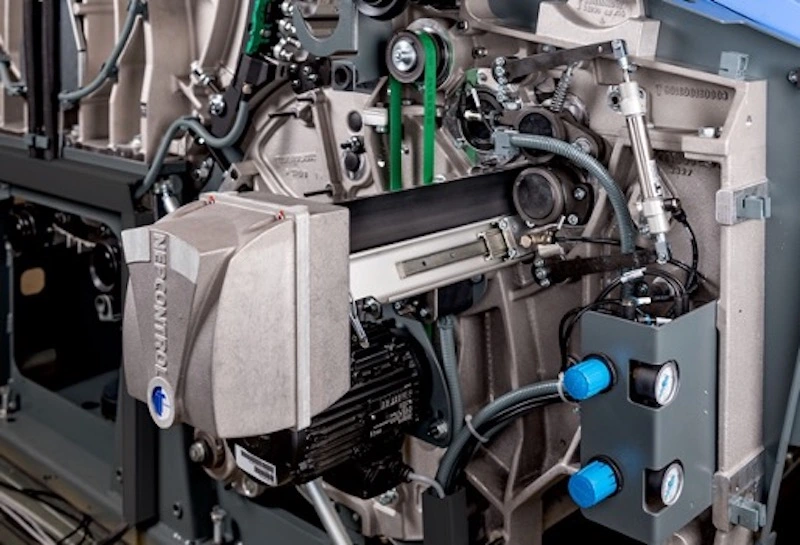

• On-line Nep counting using NEPCONTROL

• Evaluation of waste quality through WASTECONTROL

• Automatic leveling and CV% observing

• Maintenance-free servo drives

• Cans in size of 1200 mm

• Embedded grinding tools

• Long-life wires

• Smooth and uninterrupted can changing

Highlights in new Cardings

• Greater carding surface and improved productivity

• Lower expenditure on energy

• Reduced maintenance and service cost

• Decreased workload

• Easy-to-adjust settings

• Plant management system

• Automation through computerization

Leading manufacturers of Carding machine worldwide

Here is a list of the main makers in alphabetical order:

• Lakshmi Machinery Works, LMW (India)

• Marzoli Machines Textile (Italy)

• Rieter (Switzerland)

• Saurer (Germany)

• Truetzschler (Germany)

In the subsequent parts, we will look at the most important achievements in the field of carding systems. All information has been collected from the company’s website and product catalog.

Saurer Card JSC328/JSC328A

Less power consumption

By using improved and more precise technologies in the making of components such as cylinders, doffer, electronic elements and etc., it has been possible to reduce the energy consumption. Moreover, the extensive and optimal use of inverter-equipped motors has eliminated the repetitive need to change pullies.

Expanding the Carding area

Increasing the width of the machine to 1.28 meters and expanding the carding area to 3.61 square meters has increased the production. Furthermore, the increase in the length of the carding section has led to the optimized number of Flats and improved pre-carding operation and consequently the sliver quality has been superior.

By making the cylinder wider and heightened, the effective carding area has increased by 60% compared to the old conventional machines, and under the same conditions, the production has increased by more than 50%. Quantitively, the delivery rate has reached 150 kg per hour or 350 meters per minute.

Triple licker-in composition

When cotton fibers are harvested by a machine, the impurity of the sliver is high. This machine uses a triple V-shaped Licker-in system. The results showed that when Licker-in is triple, the impurity percentage goes down by 15%.

Trützschler Card TC 19i

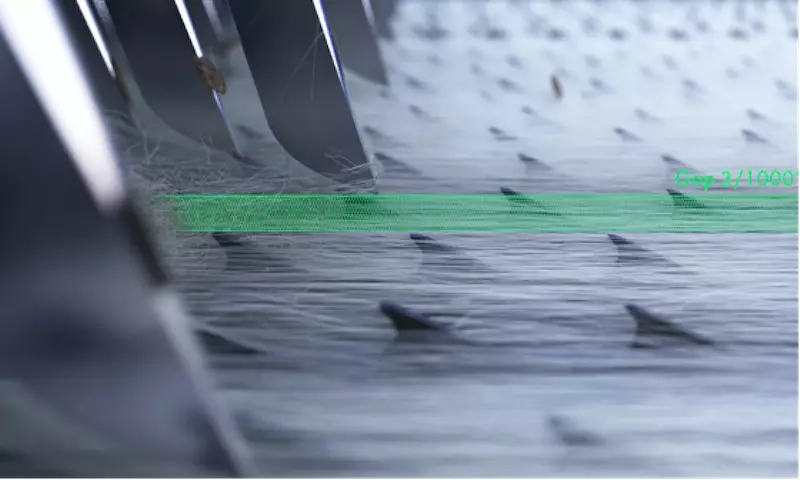

Gap Optimizer T-GO for a consistent and minimized carding area

In a spinning process, the carding operation between the cylinder and flats has a major impact on the quality of the end product. In cotton fibers, the smaller distance between the cylinder and flats, the higher quality. Even the most skilled technicians cannot apply the gap of three thousandths of an inch in the cold and standstill state of the machine. As the machine starts and the temperature rises, the centrifugal forces and the expansion of elements greatly affect the adjustments.

T-Go tool guarantees an unchanged minimum gap of three thousandths of an inch in production conditions. T-GO provides producers with a distinct quality and productivity by automatically adjusting the distance of the carding area.

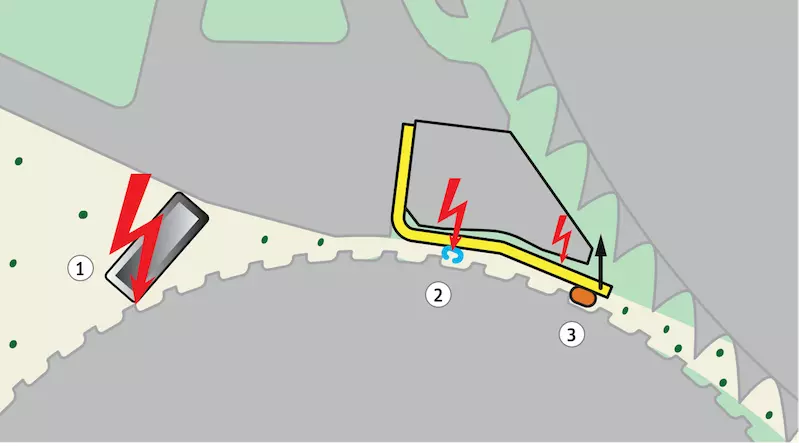

Waste monitoring with WASTECONTROL

The technology introduced by Truetzschler named WASTECONTROL helps to reduce machine waste. With this tool, there is a sensor that continuously monitors the quality of the waste removed from the most important cleaner part of the machine, Licker-in. If too many spinnable fibers are detected by the sensor, then the system changes the mote knife settings using servomotors.

Instantaneous quality control with NEPCONTROL

Reducing Nep is one of the most important functions of the carding machine. Therefore, it is important to be able to continually and in real time monitor and measure the amount of NEP in sliver, before the quality control laboratory belatedly intervenes. NEPCONTROL tool located beneath the take-off roller, monitors the web. Its camera records 20 images per second of the passing web. A powerful computer processes the images and recognize and counts the Nep, seed coats and trash.

Mill Monitoring System “My Mill”

It is accessible that the information obtained from NEPCONTROL to be sent to a data processing system named “My Mill”. The computerized data evaluation and quick display of the results help assess the following concerns:

• Actual qualitative values and their differences with the desired limits

• Deterioration in clothing performance

• Raw material changes and conditions

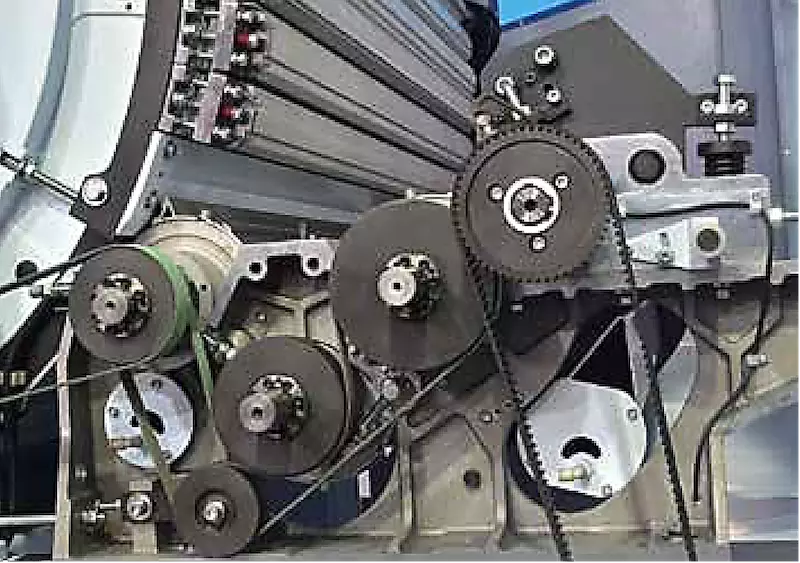

Flats clothing MAGNOTOP 3

Timely and quick replacement of flats has a noticeable effect on ensuring product quality. Speed of operation and ease of action are desirable characteristics demanded by technical workforce. With MAGNOTOP 3, Truetzschler has supplied a clothing strip that is placed on the flat bar without workshop tools and using neodymium magnetic force, while does not shift or slip.

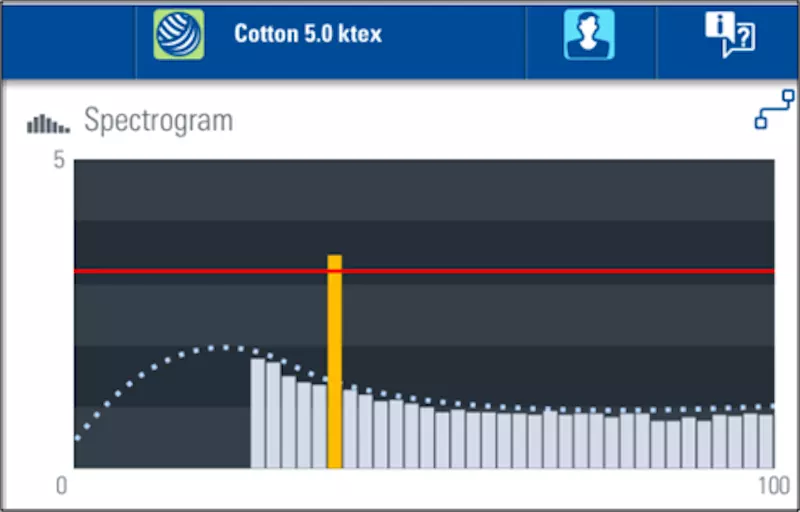

Monitoring of every meter of sliver properties such as count and evenness, Spectrogram, thick places, Neps, dirt particles and seed coat fragments in immediate, permanent and online measuring helps to manage and maintain quality.

TC19i features various sensors which read and quantify the aforementioned quality criteria and send them to a computer connected with a SMART TOUCH. The user is able to view the graphical statistics. The received data is processed and if the values are out of the predefined range and exceed the upper and lower limits, the system detects and stops the production process. It is a comprehensive quality control and is superior to random sampling and supervision.

Rieter Card C 80

Enhanced efficiency with cans of 1200 mm diameter

In order to promote production efficiency, RIETER has developed cans with a diameter of 1,200 mm, which has 43% more capacity than a can with a diameter of 1,000 mm. This feature reduces the number of sliver piecing, can changes and can transports, and hence costs and manpower are optimized.

Metal and foreign parts detector

Although in new blowing lines there is a device to detect and extract metals among the fibers, these foreign parts may still pass through the line and reach the carding and cause damage. RIETER has considered a united metal and foreign object detector in its carding so that they find and remove metal parts as soon as they enter the feeding area of the machine. This detector recognizes both small and large bodies.

Distinguishing of metal and foreign objects in stages:

1. Large metal objects

2. Small metal objects

3. Non-metal foreign objects

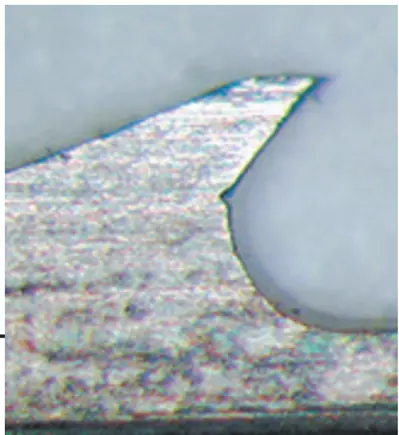

IGS-System

Due to the operation, the card clothing loses its original shape and wears out. RIETER has provided an exclusive system called IGS (The Integrated Grinding System.This tool helps to always keep the clothing sharp.

This system has two parts:

1- IGS- CLASSIC: includes a grinding stone that automatically displace across and grinds the cylinder when the machine is operating. During the pre-defined lifetime of the cylinder clothing, 400 times of grinding are performed. The grinding interval is calculated by the program.

2- IGS-TOP: It is a fully automatic option that performs the revolving flats grinding at specified intervals throughout the service life. Cycles on a preset lifespan are computed by the system.

A varied, gentle and automated grinding ensures a higher quality than the less frequent but aggressive practice.

Marzoli Card C701

INTEGRATED DRAFTING SYSTEM

Marzoli C701 can be integrated with a 3-over-3 drafting system equipped with an auto-leveler. The presence of such a feature eliminates the need for a finisher draw frame because the delivered sliver is uniform and it can be fed directly to the rotor machine. The drafting rollers are driven

by separate drive motors, and the settings are applied from the main control panel.

Final words

In this article, we tried to discuss the most recent efforts of the carding manufacturers without taking a comparative view. Details were avoided in order to deal with the technologies. Paying attention to reducing energy consumption and increasing productivity was reflected in all these machineries. We hope that in the coming years, with the introduction of artificial intelligence into the textile industry, we will see a significant improvement in the capabilities of spinning mills.

Hello. This is Christine from PengTuo Power Transmission which is specializing in bushing pulley covering European and USA standard. Should any of bushing pulley of interest to you, pls let us know.

We will be happy to give you a quotation upon receipt of your detailed requirements. If you are interested in our product, you could check our web in advance.

Look forward to hearing from you soon.