Knitwear has had a career that is as winding as it is steep: as early as 1900 BC, some tribes of Asia Minor knew how to intertwine finite threads to form a net work – the fillet.

This technique is not dissimilar to knitting and is still used today in the production of special lace. At that time, however, no one could have predicted the development of knitwear.

Neither could they have predicted the high demands they would have to meet during production. Stephan Kehry, product manager for textiles at Mahlo GmbH + Co KG, talks about how manufacturers can meet these demands and work economically at the same time.

First of all, a brief digression on the definition and development of knitwear. Stitch formation, i.e. the interlocking of thread loops formed from one or more threads, is the basis for knitwear.

The simplest form of loop formation is created by wrapping the fingers of one hand alternately with a thread and then lifting the lower loop over in each case. “You can vividly imagine how our ancestors followed this very principle when they first attempted knitting,” says Stephan Kehry, product manager for textiles at Mahlo GmbH + Co. KG. From the DNA, the knitting dolly is a direct ancestor of this technique.

The simple machine production and the wide range of applications quickly established knitwear as a mass product. Quality played a subordinate role.

“It was only with the advent of technical textiles that the “value side” of knitwear was born,” says Kehry. In particular, the three-dimensional possibilities of the textile made it possible to reproduce properties that had previously been denied to normal structures, such as spacer fabrics in mattress covers or handle plush in car headliners. Today, knitted fabrics can be found in modern sports shoes as well as in artificial leather applications or geotextiles.

Growing demands on textiles

So today knitwear takes on a variety of demanding tasks. But what impact does this have on the production of the fabric? A big one, as the Mahlo expert points out. “Because with the diversification also came the demand.”

Especially when it comes to technical textiles, angular position and stitch density have to be right. In many cases, applications are applied to the textile. “Here, too, quantity and thickness must be constantly controlled.”

In the example of shoe material, on the other hand, the repeat and the position of the article play an overriding role. “When the customer spends sometimes several hundred euros on high-tech sports shoes, the function and appearance must ultimately be right down to the last detail,” Kehry explains.

And, of course, it is always a matter of operating efficiently, not wasting raw materials and working sustainably.

To meet these demands, manufacturers must optimise their production processes. There are various ways to do this. Thread-straight fabric is the basis for high-quality fabric. “To achieve this, the position of the stitches in the textile structure must be reliably determined during the ongoing production process and automatically passed on to a straightening unit via evaluation software. “In other words, in the best case, predicting the development of distortions and eliminating them before they even occur.”

Uniform fabric and correct thread density

However, according to Kehry, the thread density is just as important as the correct alignment of the threads to each other. “Due to the wet finishing of textiles, which are usually sensitive to tension, there are often differences in the weight profile.

If these differences are detected in time, correcting the bias in the stenter frame allows a lot of things to be repaired before complaints arise.”

To measure the thread density, powerful sensor technology is needed that detects the highest possible thread count per centimetre, compares it with the preset value and transmits the corrections in real time to the leading of the stenter frame.

“This is how you get uniform fabric with exactly the right stitch density.” Ideally, the measurement calculates the fabric weight at the same time. For knitwear in particular, this is an important parameter for a flawless end product, as the goods are often invoiced in kilograms and not in metres.

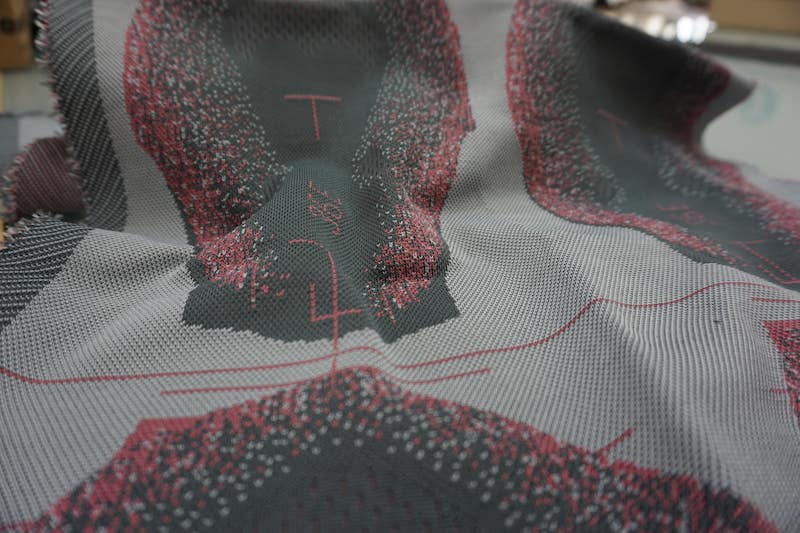

In some cases, however, the process goes far beyond stitch density. For example, in the case of lace for underwear articles or shoe uppers. Particularly in the production of shoes, efficiency and precision are equally important today.

Efficiency in the utilisation of the fabric width due to the different shoe profiles; precision in order to transmit the exact position and circumference of the individual patterns to the computer in charge during the subsequent cutting process – and thus to finish this process fully automatically with “zero defect”.

Nowadays, modern “line scan cameras” are often used for this purpose, which precisely determine the position of the individual elements with the highest possible resolution. “Here, too, the manufacturer can make a correction by means of a straightening device or by controlling the leading edge, so that possible defects are eliminated in time,” Kehry explains.

Reproducible product properties

In general, there is still a lot of untapped potential at the end of the value chain of technical knitwear, the Mahlo product manager is certain.

Be it in optimising the fixing time by continuously monitoring the fabric temperature or by controlling the residual moisture: In both cases, it is a matter of not wasting any safety margin and still implementing absolute process reliability. Whereby the residual moisture in particular not only has an impact on the efficiency of the dryer.

An over-dried product often has a lower wetting capacity and therefore leads to irregularities in subsequent applications.

In general, the strength of any finisher in the textile industry lies in keeping an eye on all subsequent processes while trying to optimally complete the current finishing step with all given means. This becomes particularly clear when applying specific additives, as is often required especially for technical articles.

Parameters such as thickness, weight, air permeability or even composition of the coating should be closely examined and compared during the production process in order to obtain a flawless end product that can perform its tasks.

In order to be successful in the long term in this demanding sector, manufacturers must accompany and optimise their processes in terms of quality.