The IMA Tissue&Nonwoven hub will attend IDEA 2022 in Miami Beach, Florida, from March 28th to 31st. Innovative solutions to convert and pack face masks and respirators, safe production of disinfectant wet wipes and sustainable solutions for the recyclable packaging of nonwovens will be under the spotlight during the exhibition.

The main international exhibition for the Nonwovens Industry will be the perfect occasion to get in touch with the full array of developments.

IMA Tissue&Nonwoven is IMA’s cluster of companies that includes five main actors in these sectors, proposes itself as main contractor for complete lines for wet wipe and face mask converting and packing and for the nonwovens packaging markets.

A CONCRETE PARTNER

As a Concrete Partner, the strength of IMA Tissue&Nonwoven resides into the gathering of a pool of vertically specialized companies, joined by one vision: offering its customers complete and tailored solutions, with a commitment to sustainability.At IDEA, visitors will have the chance to get in touch with the IMA brands specialized in the Nonwovens field.

IMA TMC – Tissue Machinery Company

IMA TMC, specialist in the field of Nonwovens Packaging, will present D-NAMIC: a new stacking and bagging machine for the sustainable packaging of baby & adult diapers, light incontinence and bed underpads. With a very compact footprint, this machine features high-speed output up to 75 bags/minute.

The machine can run with either plastic or paper-based films, both recyclable and in accordance with sustainability practices. Perfect completion of the line is reached with TMC’s bundler: D-BUND is the diaper bundler tailored for every manufacturer’s need, up to 12 cycles per minute, overwrapping diaper bags in neat, tight, completely sealed bundles ready for transport and distribution.

IMA TMC’s D-NAMIC – stacking and bagging machine for the sustainable packaging of baby & adult diapers, light incontinence and bed underpads

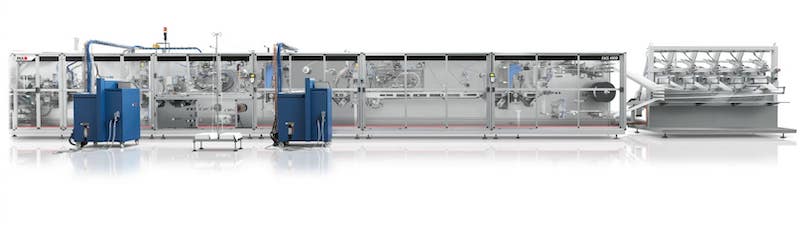

TEKNOWEB CONVERTING

The longstanding experience of TEKNOWEB CONVERTING in the market of face masks and wet and dry wipes will be in the spotlight.

IMA Face 400 and IMA Face 400D are the converters dedicated to the production of surgical face masks and respirators (FFP2/N95); call at the booth to discover the advantages of ultrasonic sealing. Explore our solutions for three-pieces respirators with exhalation valve at high speed.

That of wet wipes is an industry that has seen an important rise since the spread of Covid-19 pandemic: disinfectant wet wipes soaked in alcoholic solutions for personal and home care are now one of the most requested products on the market. Discover Teknoweb’s machinery for IPA alcohol disinfectant wipes, compliant to the explosion proof regulations. Explore our raw materials sustainable and dispersible solutions, up to 300 stacks per minute.

Teknoweb’s IMA Face 400D – Converter for the production of surgical face masks and respirators

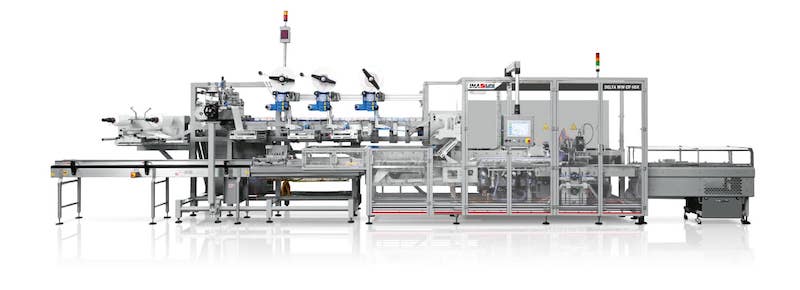

IMA ILAPAK

Pioneers in the design of revolutionary flow wrapping solutions dedicated to innovative, reclosable and attractive packs, IMA ILAPAK stands out today as a market leader in both the wet and dry wipes industry. At IDEA you’ll get the chance to discover Delta WW OF-HSX, a first-class flow wrapper for wet wipes already showcased at INDEX 20. As for IMA’s converters, this machine can be full ATEX compliant and ready for sustainable packaging, running up to 170 packs per minute with traditional laminated films and up to 130 packs per minute with fully recyclable materials.

IMA Ilapak’s Delta WW OF-HSX – Flow wrapper for wet wipes

SUSTAINABILITY MATTERS: IMA ZERO

IMA Tissue&Nonwoven is committed to sustainable practices, which are a fundamental pillar of IMAGroup.

IMA ZERO, born in 2019, is the foundation of the Group’s sustainable development programme. It has the ultimate goal of minimizing environmental impact in industrial manufacturing, and of promoting and creating a working and living habitat that always puts people at the centre. IMA ZERO is composed of 4 main programs: NoP (No-Plastic Program), LOW (Low Impact Program), E-MOB (Sustainable Mobility Program) and YOU (Human-Centric Program).

All these pillars put at the forefront the environment and the people living in it.

In the packaging industry, adopting sustainable solutions is a mandatory challenge: through the research and testing of alternative processes and materials, together with specialised partners, IMA NoP fosters plastic-free and sustainable, compostable or biodegradable packaging solutions.

For this purpose, IMA has established the OPENLab: a series of laboratories where Material Technologists study, develop and test compostable and recyclable materials to be used on its packaging equipment.

IMA ZERO is our very latest promise to create products, production processes and services, benefitting from a renewed logic of sustainability and from the awareness that our commitment today will help to shape the world of tomorrow.